Method for rapidly eliminating nodules on surfaces of furnace rollers

A furnace roller and nodulation technology, which is used in grinding machine parts, workpiece feed motion control, grinding machines, etc., can solve problems such as economic losses and batch products that do not meet requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

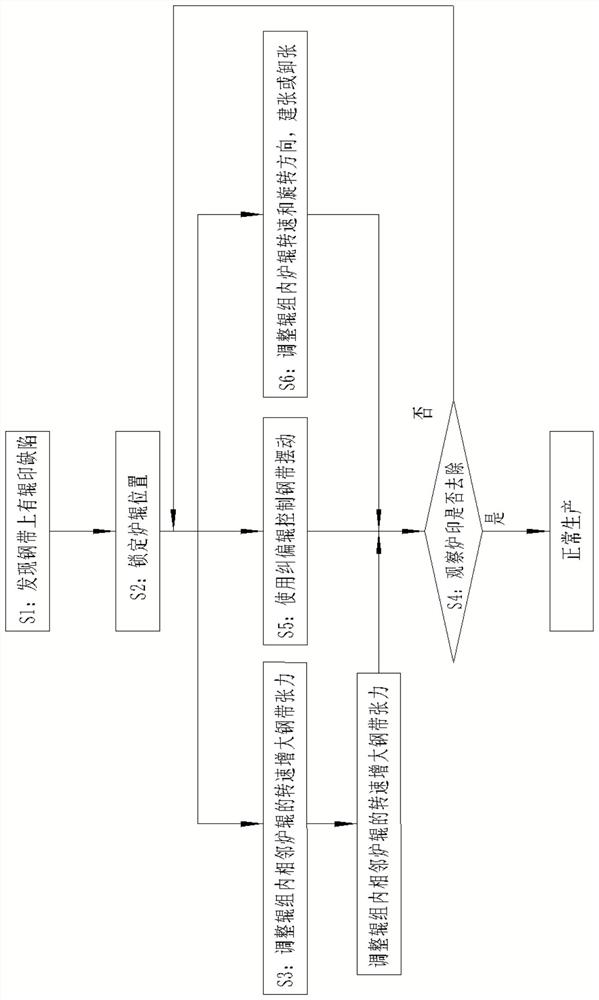

[0039] Preliminary steps:

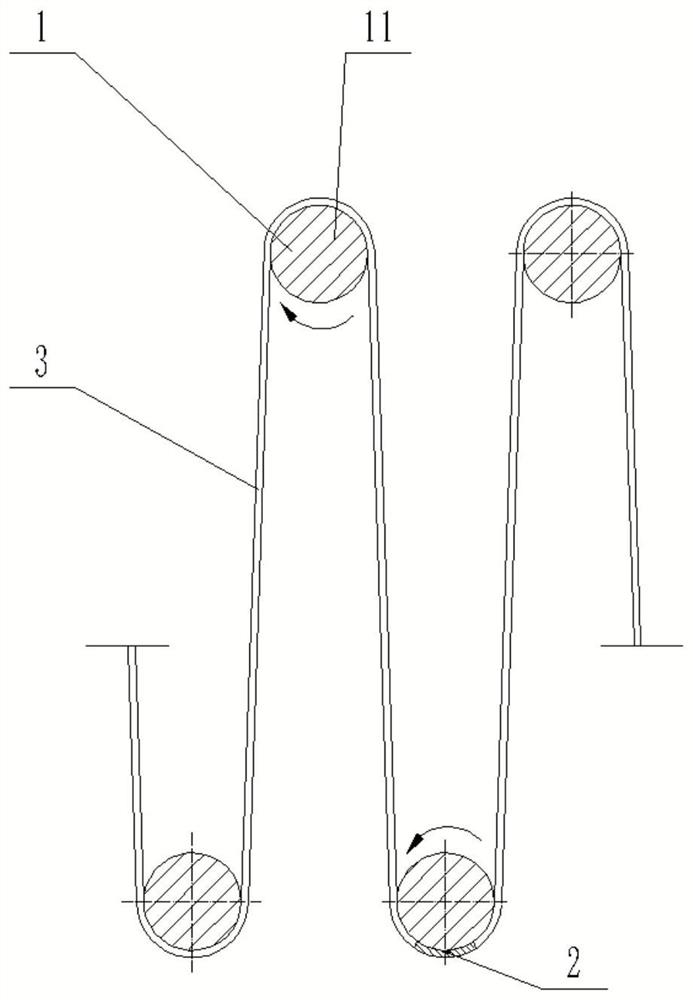

[0040] When the continuous annealing furnace is in normal operation, if the surface appearance inspection equipment or artificially finds roll marks on the surface of the steel strip (SPCC: generally cold-rolled carbon steel sheet and steel strip) 3, immediately take measures to reduce the transmission speed of the steel strip 3, reduce the The flame nozzle method reduces the temperature of the continuous annealing furnace, etc. The reduction of the speed is to reduce the output of defective steel strips, and the temperature of the annealing furnace is correspondingly reduced to avoid the overheating and melting of the steel strips due to the reduced speed. Generally, the thickness of the steel strips in normal production is 0.1 to 3.0 mm, the width is 500~1800mm.

[0041] Manually intercept part of the steel strip 3 carrying the roll marks, grab this part of the steel strip 3 to the quality inspection station, measure the length of the adjacent rol...

Embodiment 2

[0056] (2) The correction roller in the control roller group drives the steel belt to reciprocate and swing along the furnace roller axis to remove nodules:

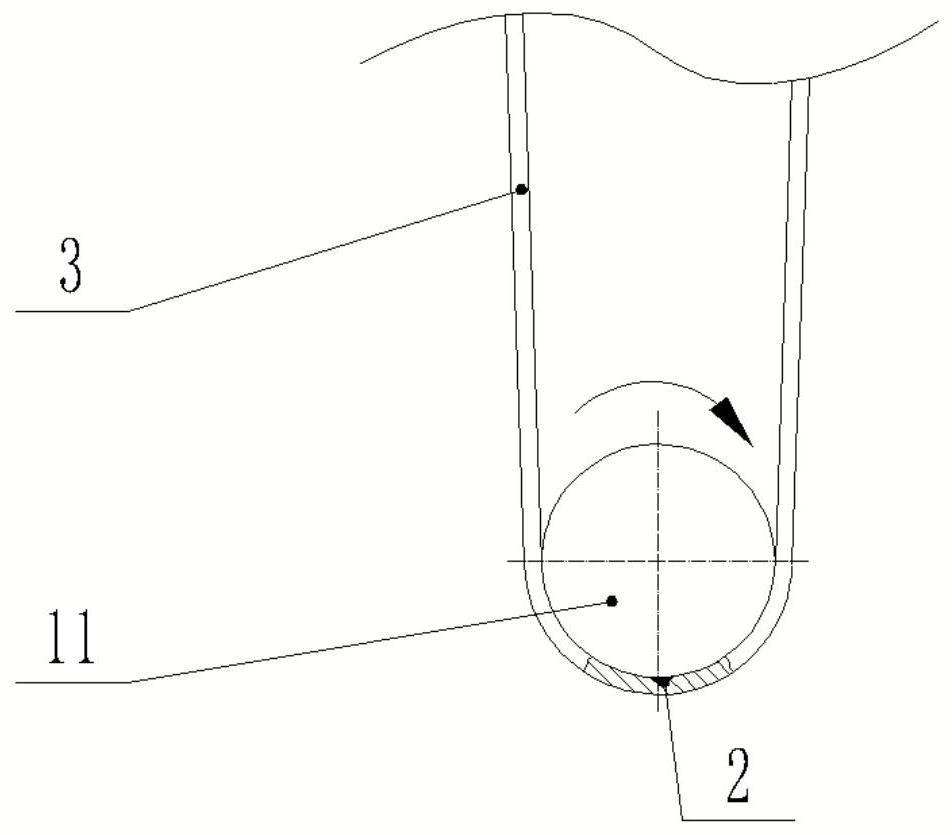

[0057] Some furnace marks are caused by burrs on the steel strip 3, which are in the shape of flat flakes. This kind of nodules 2 cannot be pressed into the inside of the steel strip 3, so the method in the first embodiment cannot be used to eliminate them. To this end, the following method is provided to eliminate such nodules2.

[0058] In the continuous annealing furnace, there is a deviation correcting roller 12 for preventing the deviation of the steel strip 3, and the parameters of the control panel of the continuous annealing furnace are adjusted so that the furnace roller 12 in the area of the furnace roller 11 carrying the nodules 2 controls the steel strip 3 along the axis of the furnace roller 11 To the reciprocating swing, because the furnace roll 11 is in a rotating state, when the nodule 2 on the furnace ...

Embodiment 3

[0060] (3) Control the positive and negative directions of the furnace rolls in the roll group to repeatedly adjust the rotation direction to remove nodules:

[0061] In order to further remove nodules 2, the present invention also provides a method for repeatedly unstrapping (releasing the tension) and establishing tension (establishing tension) for the steel strip 3, and its specific operation method is the same as that of Embodiment 1.

[0062] The rotation direction and speed of each furnace roller 11 are all controlled by the console of the continuous annealing furnace, and the motor driving the rotation of the furnace roller 11 is a frequency conversion motor, which can control the rotation speed of the furnace roller 11. When the furnace roller 11 rotates in the opposite direction to the transmission of the steel strip 3 at the same time, the steel strip 3 is unloaded. , the furnace roller 11 continues to keep rotating, and rubs on the steel strip 3, and nodules 2 fall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com