Thick and large ore body non-explosive mining method based on intelligent heading machine

A technology of thick and large ore bodies and mining methods, applied in ground mining, mining equipment, underground mining, etc., can solve the problems of low degree of mechanization and intelligence, limited production capacity, low mining efficiency, etc., and achieve high filling structure strength , good stress conditions, and the effect of improving filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be clearly and completely described below in conjunction with embodiments.

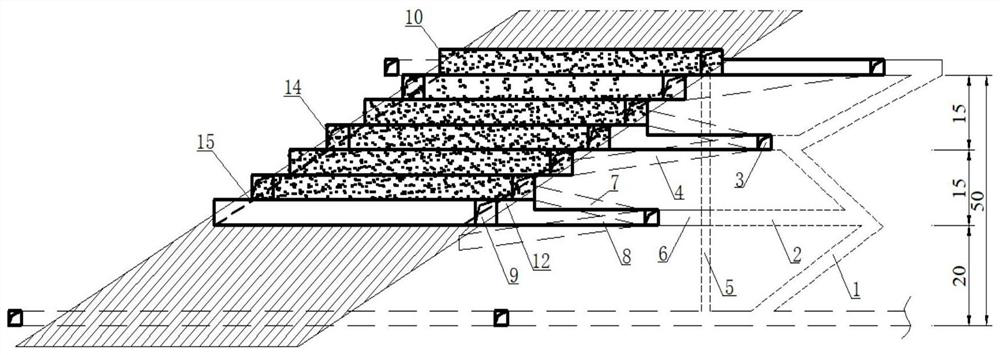

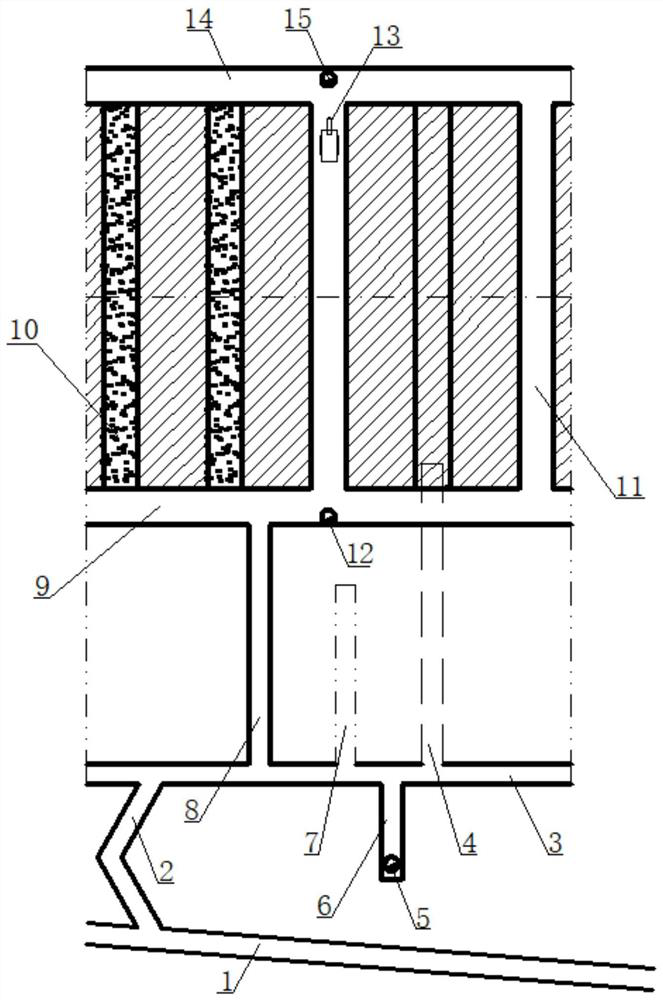

[0020] Such as Figure 1-Figure 3 As shown, the non-explosive mining method for thick and large ore bodies based on the intelligent roadheader provided by the embodiment of the present invention is suitable for the mining of weak, broken, unstable, and high-value hard rock ore bodies with a thickness of 20 m and above, and is a mechanical mining method. Provided new ideas.

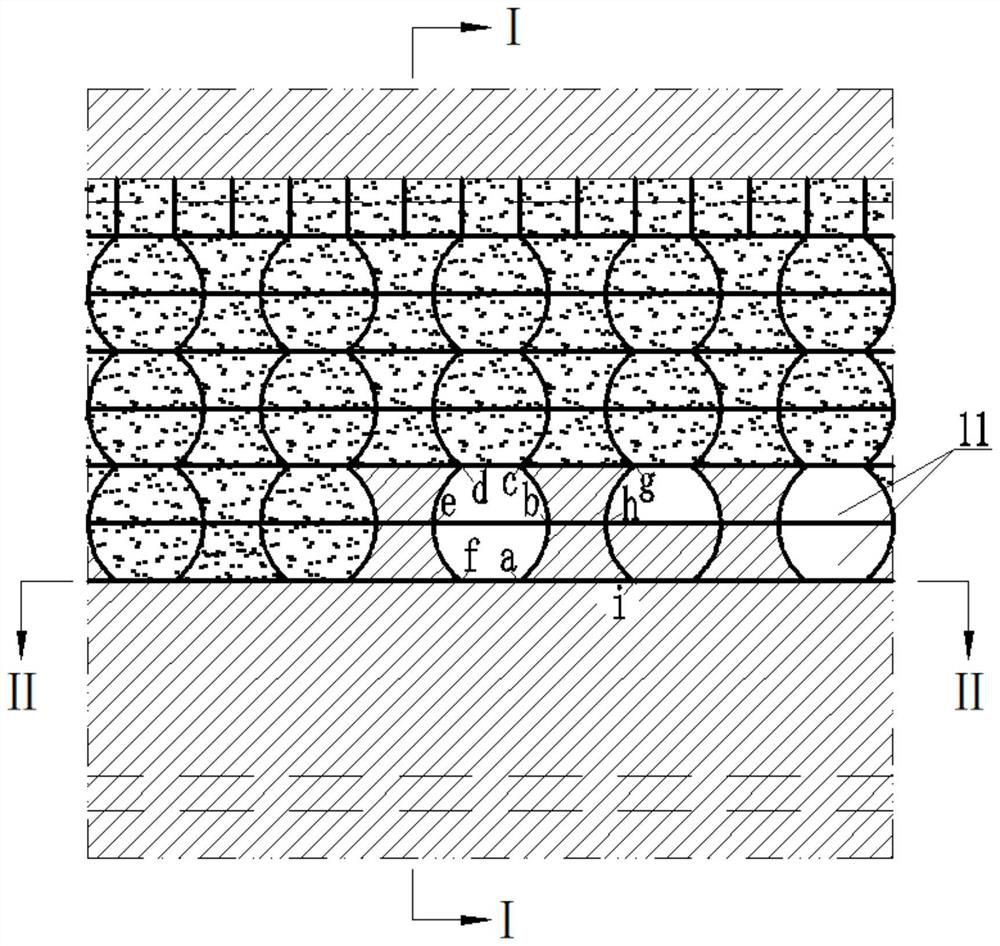

[0021] The embodiment of the present invention provides a non-explosive mining method for thick and large ore bodies based on intelligent roadheaders. The method includes: dividing the thick and large ore bodies into multiple panels along the strike, and the panels are vertically divided into multiple segments. There are multiple layers in the segment, and each layer is divided into a number of vertical mining approaches 11 .

[0022] Each panel is 42-112m long, the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com