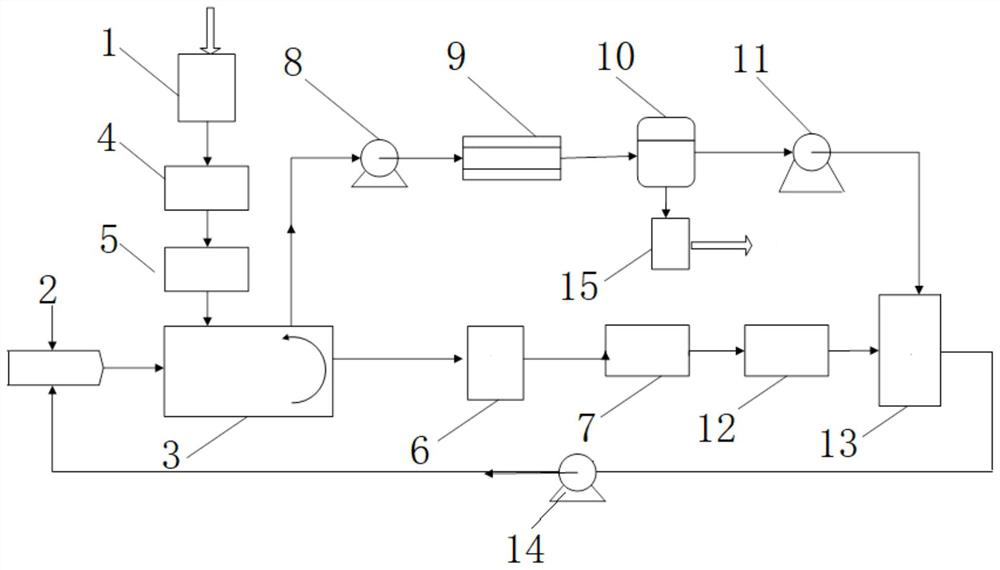

Biochemical herb residue drying and pulverized coal boiler coupling incineration system

A pulverized coal boiler and biochemical technology, applied in the direction of incinerators, combustion types, combustion equipment, etc., can solve the problems of boiler thermal efficiency decline, mixed combustion efficiency, and low disposal volume, so as to reduce boiler efficiency and reduce flue gas The effect of increasing the volume and improving the disposal capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The thermal power plant boiler with a single unit rated capacity of 300MW (rated evaporation capacity of 1028t / h) that has completed ultra-low emission transformation has a designed coal consumption of 132t / h under the condition of the boiler’s maximum continuous evaporation capacity. It is equipped with SCR denitrification device, high-efficiency electrostatic dust removal, and wet limestone-gypsum desulfurization device to achieve ultra-low emissions.

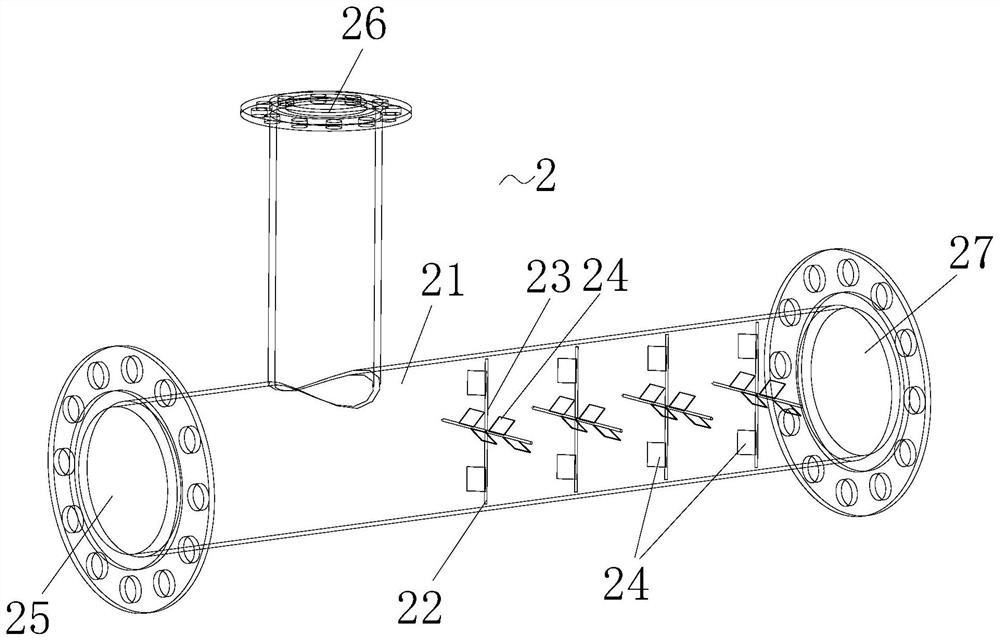

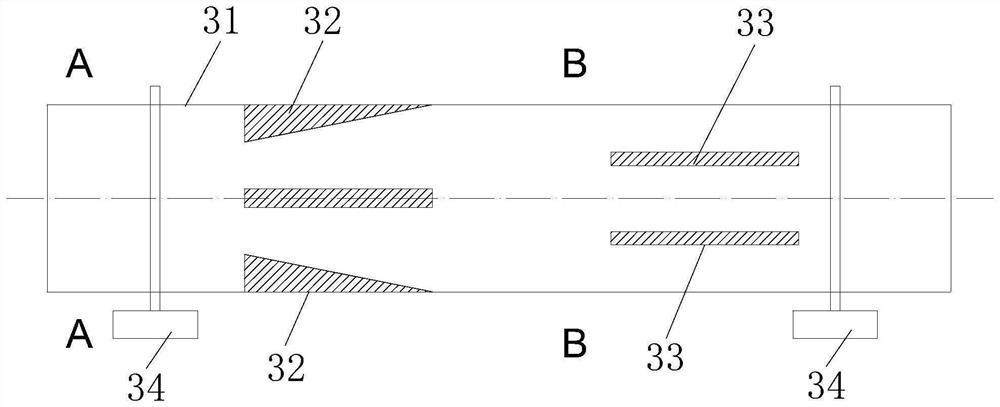

[0057] Now, through technological transformation, a biochemical dregs receiving and drying feeding blending system that can handle 100t / d has been built. Under the design load of 100%, 4.2t / h of biochemical residues (with a moisture content of 80%) are transported to the drum drying chamber, and then incinerated in the furnace after drying, with a mass blending ratio of 3.2%. At the same time, the high-temperature flue gas (450-650°C) and a certain amount of ambient air (accounting for 0-50% of the high-temperature flu...

Embodiment 2

[0061] The thermal power plant boiler with a single unit rated capacity of 300MW (rated evaporation capacity of 1028t / h) that has completed ultra-low emission transformation has a designed coal consumption of 132t / h under the condition of the boiler’s maximum continuous evaporation capacity. It is equipped with SCR denitrification device, high-efficiency electrostatic dust removal, and wet limestone-gypsum desulfurization device to achieve ultra-low emissions.

[0062] Now, through technological transformation, a biochemical dregs receiving and drying feeding blending system that can handle 100t / d has been built. Under the design load of 100%, transport 4.2t / h biochemical residue (moisture content 80%) to the drum drying chamber, after drying, it will be temporarily stored in the buffer warehouse and then incinerated in the furnace to increase its quality and the proportion of mixed combustion is 6.4%. At the same time, the high-temperature flue gas (450-650°C) and a certain ...

Embodiment 3

[0066] The thermal power plant boiler with a single unit rated capacity of 300MW (rated evaporation capacity of 1028t / h) that has completed ultra-low emission transformation has a designed coal consumption of 132t / h under the condition of the boiler’s maximum continuous evaporation capacity. It is equipped with SCR denitrification device, high-efficiency electrostatic dust removal, and wet limestone-gypsum desulfurization device to achieve ultra-low emissions.

[0067] Now, through technological transformation, a biochemical dregs receiving and drying feeding blending system that can handle 100t / d has been built. Under the design load of 100%, transport 4.2t / h biochemical residue (moisture content 80%) to the drum drying chamber, after drying, it will be temporarily stored in the buffer warehouse and then incinerated in the furnace to increase its quality and the proportion of mixed combustion is 6.4%. At the same time, the high-temperature flue gas (450-650°C) and a certain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com