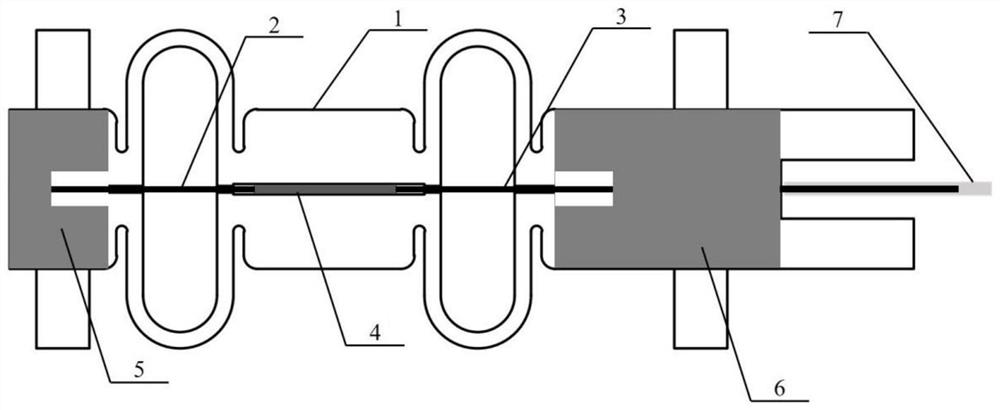

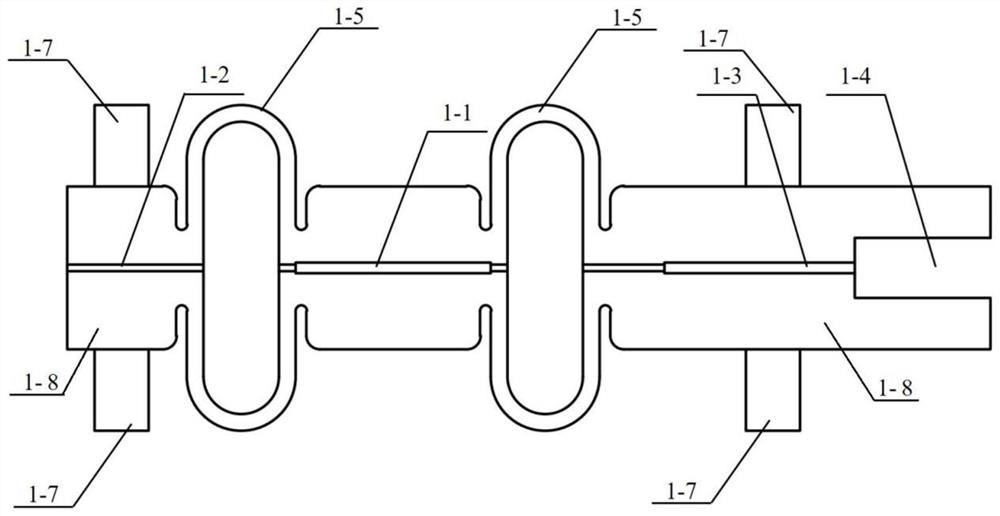

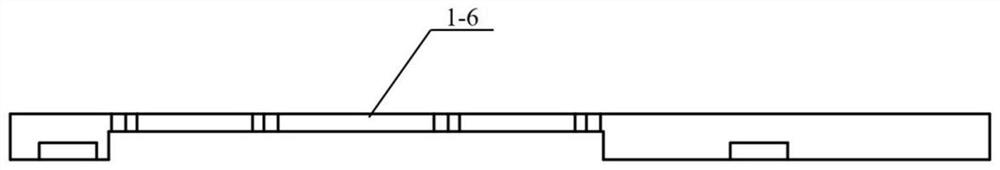

High-temperature-resistant and high-pressure-resistant optical fiber strain sensor

A technology of optical fiber strain and high temperature resistance, applied in instruments, optical devices, measuring devices, etc., can solve the problem that the strain sensor cannot work stably for a long time, and achieve strong anti-electromagnetic interference ability, small size, and high measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] This embodiment provides a high temperature and high pressure resistant optical fiber strain sensor. The optical fiber sensing technology is a high-precision measurement technology; the optical fiber itself has the advantages of fast transmission speed, strong anti-electromagnetic interference ability, corrosion resistance, high temperature resistance and high safety. Therefore, it has been widely used in aerospace, energy, construction and other industrial and military fields. The fiber optic Fab sensor is a typical representative of the fiber optic sensor. With the development of various high-precision processing and assembly technologies, various types of fiber optic Fab sensors have emerged. The fiber-optic F-P sensor can be used to construct the F-P cavity in different forms. The shape of the sensor is flexible and can be used in many different measurement environments. At the same time, the fiber-optic F-P sensor has a simple structure, is not easily affected by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com