An online flight test system and its test method

A flight test and tester technology, which is used in the testing of machine/structural components, measuring devices, aerodynamic tests, etc. low impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

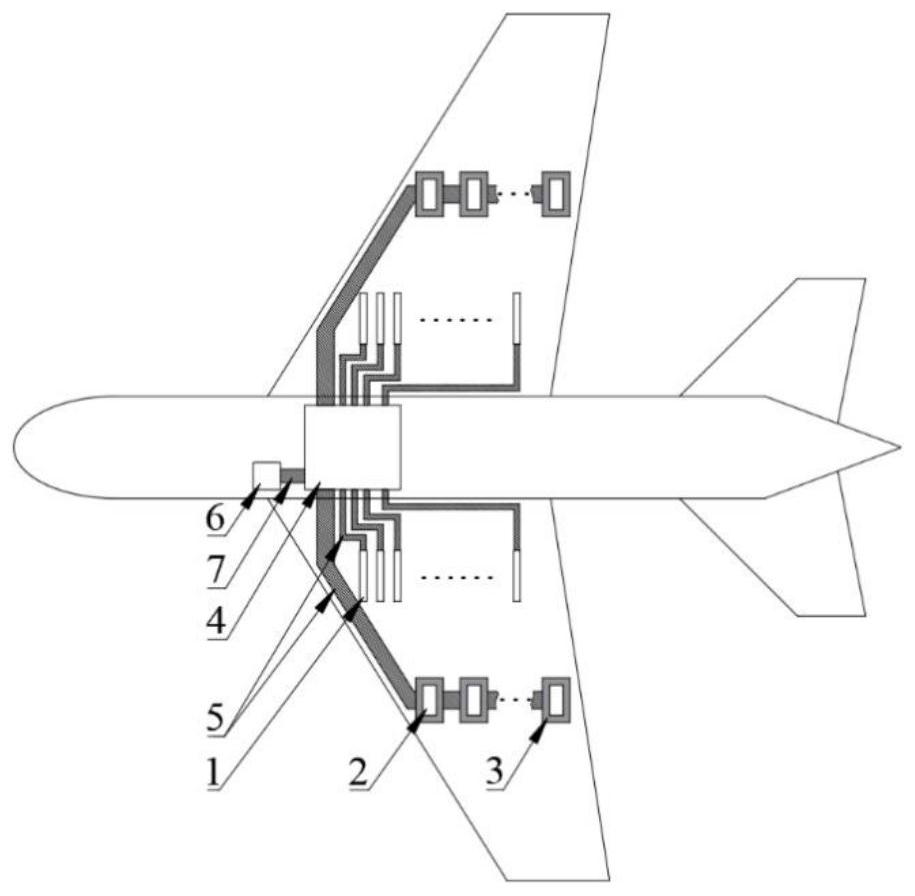

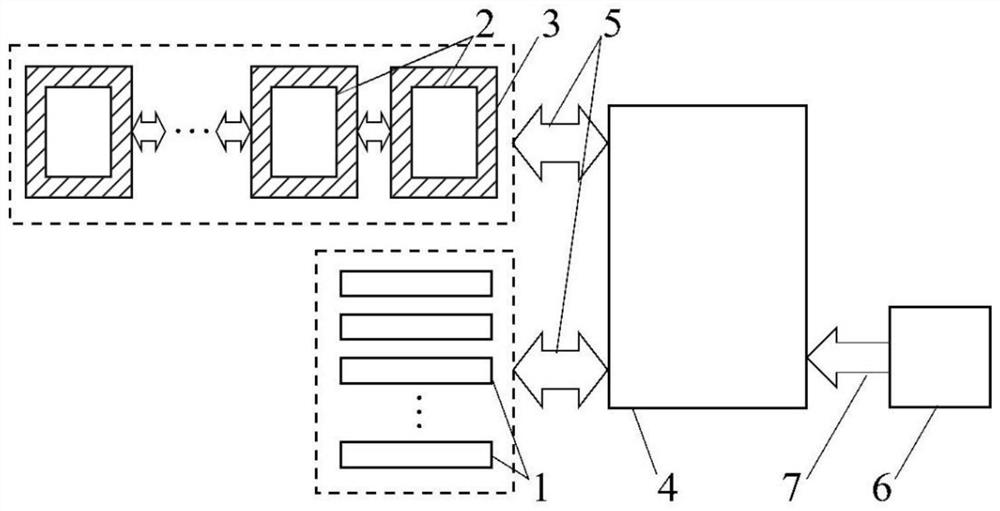

[0050] The shear stress test node module is electrically connected to the tester in parallel mode, and the stress test node module is electrically connected to the tester in series mode.

[0051] In the parallel mode, each node is individually connected to the tester, and the tester performs excitation and signal processing; in the series mode, the first node is connected to the tester, and subsequent nodes are connected to the previous one one by one. node.

[0052] The serial mode test node includes a flexible substrate, a control unit and a sensing unit. The sensing unit is a piezoresistive, piezoelectric or capacitive pressure sensor. The control unit is used for controlling the signal acquisition of the sensor to be synchronized with the network.

Embodiment 2

[0054] The shear stress test node module is electrically connected to the tester in series mode, and the stress test node module is electrically connected to the tester in parallel mode.

[0055] In the parallel mode, each node is individually connected to the tester, and the tester performs excitation and signal processing; in the series mode, the first node is connected to the tester, and subsequent nodes are connected to the previous one one by one. node.

[0056] The serial mode test node includes a flexible substrate, a control unit and a sensing unit. The sensing unit is a floating type, thermal type or bottom partition type wall shear stress sensor. The control unit is used for controlling the signal acquisition of the sensor to be synchronized with the network.

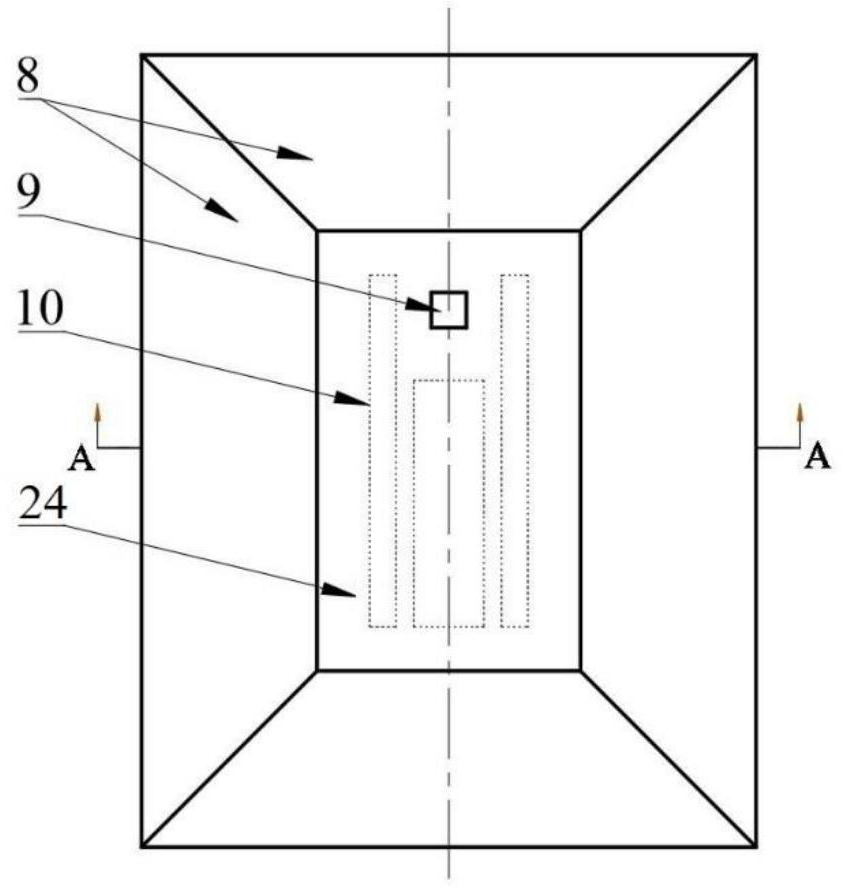

[0057] In the first embodiment and the second embodiment, a first node fairing and a second node fairing are attached above the shear stress test node module and the pressure test node module, respectively. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com