PFC voltage-regulating resonant MIG welding power supply system and control method

A technology of power supply system and resonant converter, which is applied in the direction of control/regulation system, adjustment of electrical variables, electrical components, etc., and can solve the problems of LLC resonant converter deviating from the optimal resonance point, application limitations of LLC resonant converter, and efficiency decline, etc. , to achieve high-quality welding effect, high energy conversion efficiency, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

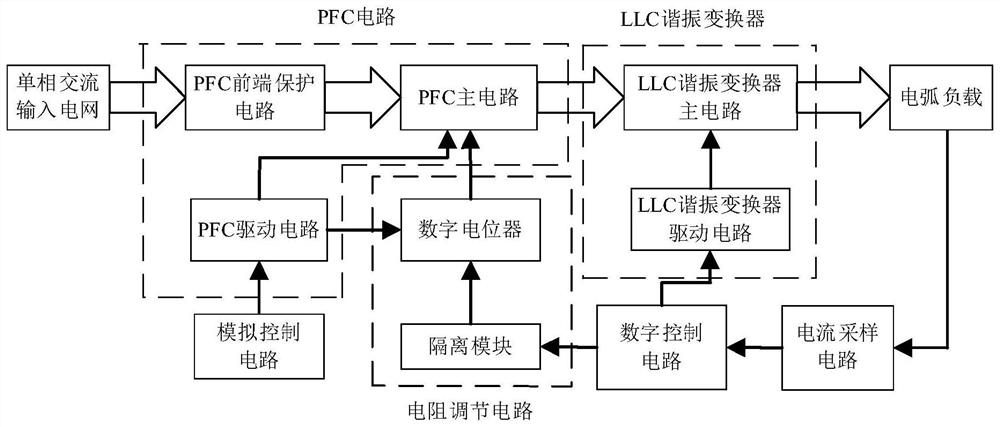

[0038] Such as figure 1 As shown, a PFC voltage-regulated resonant MIG welding power supply system includes a single-phase AC input grid, PFC circuit, LLC resonant converter, digital control circuit, analog control circuit, current sampling circuit, resistance adjustment circuit and arc load.

[0039] The single-phase AC input grid, PFC circuit, LLC resonant converter and arc load are connected in sequence.

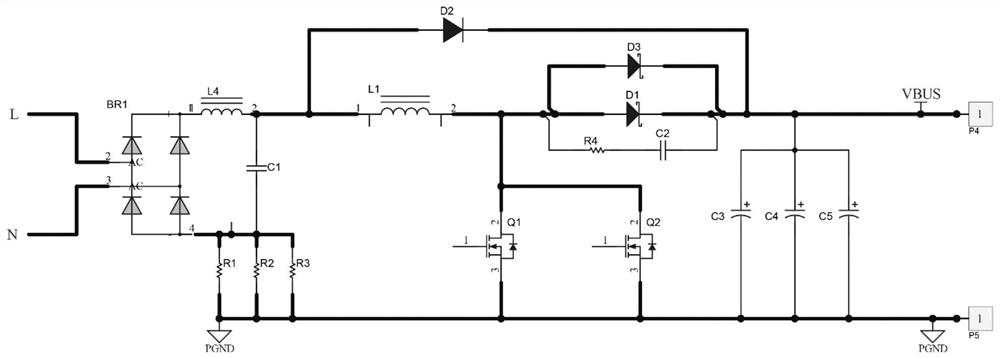

[0040] The PFC circuit includes a PFC main circuit, a PFC front-end protection circuit and a PFC drive circuit.

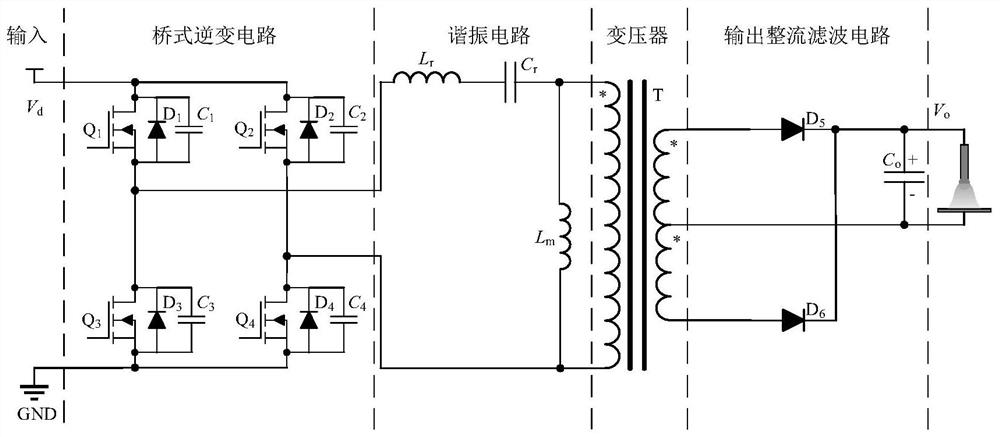

[0041] The LLC resonant converter includes an LLC resonant converter main circuit and an LLC resonant converter drive circuit.

[0042] The resistance adjusting circuit includes a digital potentiometer and an isolation module.

[0043] One end of the PFC front-end protection circuit is connected to the single-phase AC input grid, and the other end is connected to the PFC main circuit.

[0044] One end of the PFC drive circuit is connected to the analog cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com