Automatic feeding device for copper plate

An automatic feeding device, copper plate technology, applied in the stacking, transportation and packaging of objects, electrolysis process, etc., can solve the problems of solution splashing, human injury, etc., achieve stable parameters, avoid human injury, and avoid unstable factors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

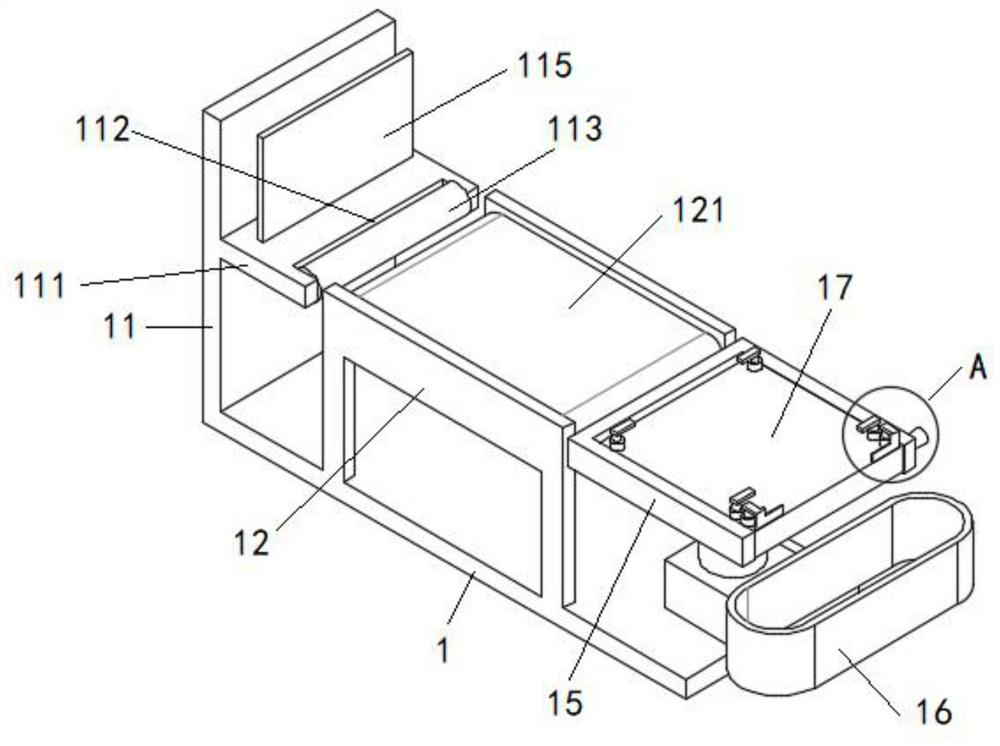

Examples

Embodiment 2

[0033] A kind of automatic feeding method, described automatic feeding method comprises:

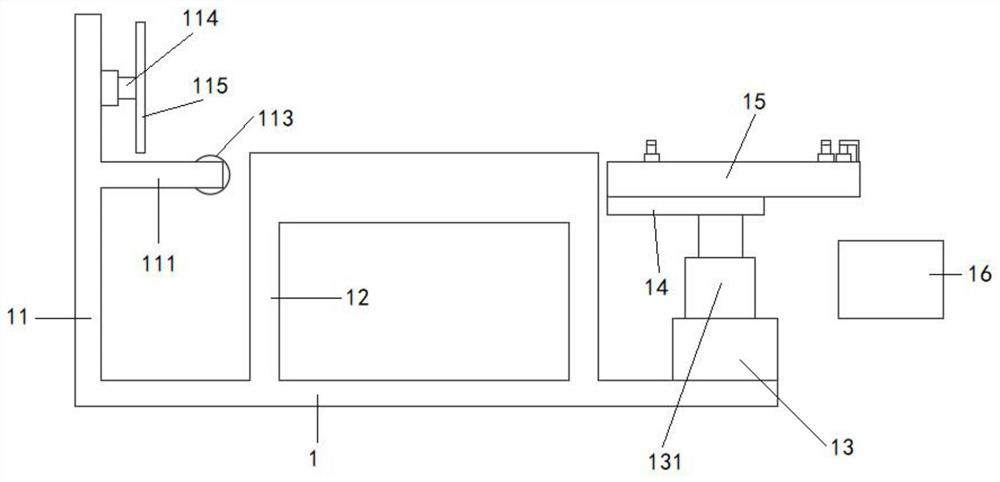

[0034] Stp1, a plurality of copper plates are vertically placed on the support plate 111, then stretch out by controlling the material pushing cylinder 114 and the material shifting roller 113 to rotate, so that the copper plates are adjusted to be horizontal and placed on the conveyor belt 121;

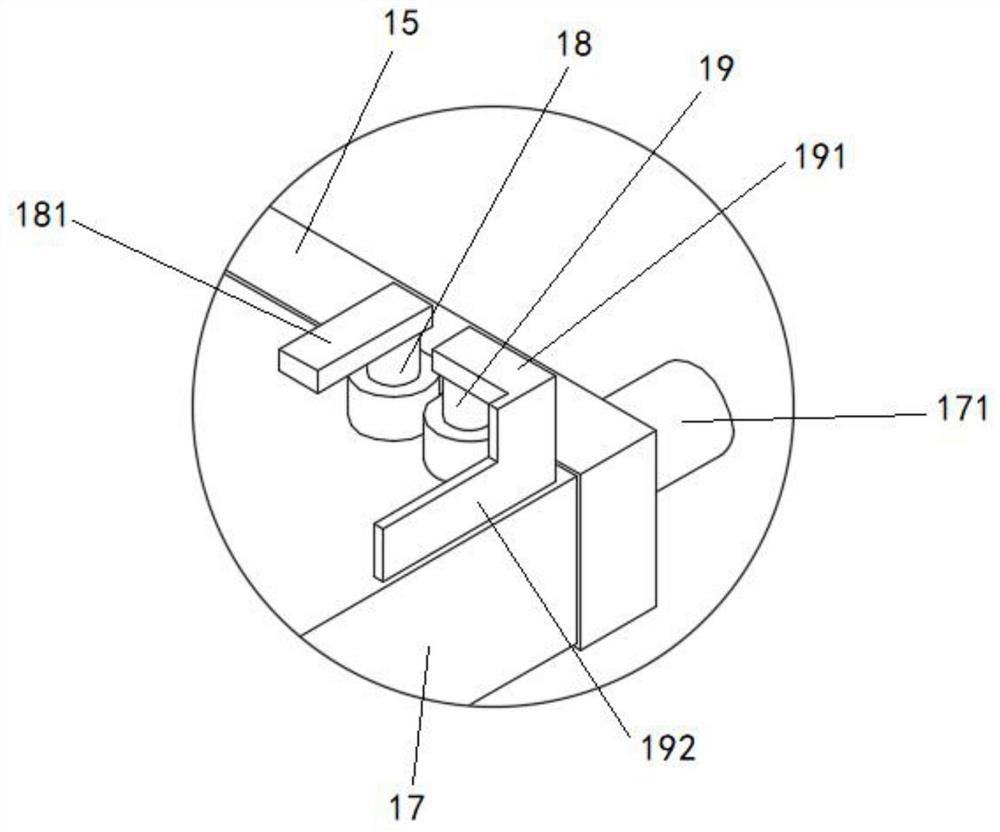

[0035] Stp2, the copper plate moves to the pallet 17 under the action of the conveyor belt, and after the pressure sensor detects the pressure signal, the micro telescopic cylinder 18 is controlled to retract so as to realize the clamping of the copper plate placed on the pallet 17 by the clamping plate 181;

[0036] Stp3, drive the rotary motor A171 to rotate, so as to facilitate the control of the tray 17 to be tilted or vertical, then control the rotary motor B19 to rotate, control the removal of the baffle plate 192, and then control the extension of the miniature telescopic cylinder 18, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com