Method, device and equipment for accurately adjusting ADC camera and computer storage medium

A camera and precise technology, applied in chemical instruments and methods, self-melting liquid pulling method, single crystal growth, etc., to achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

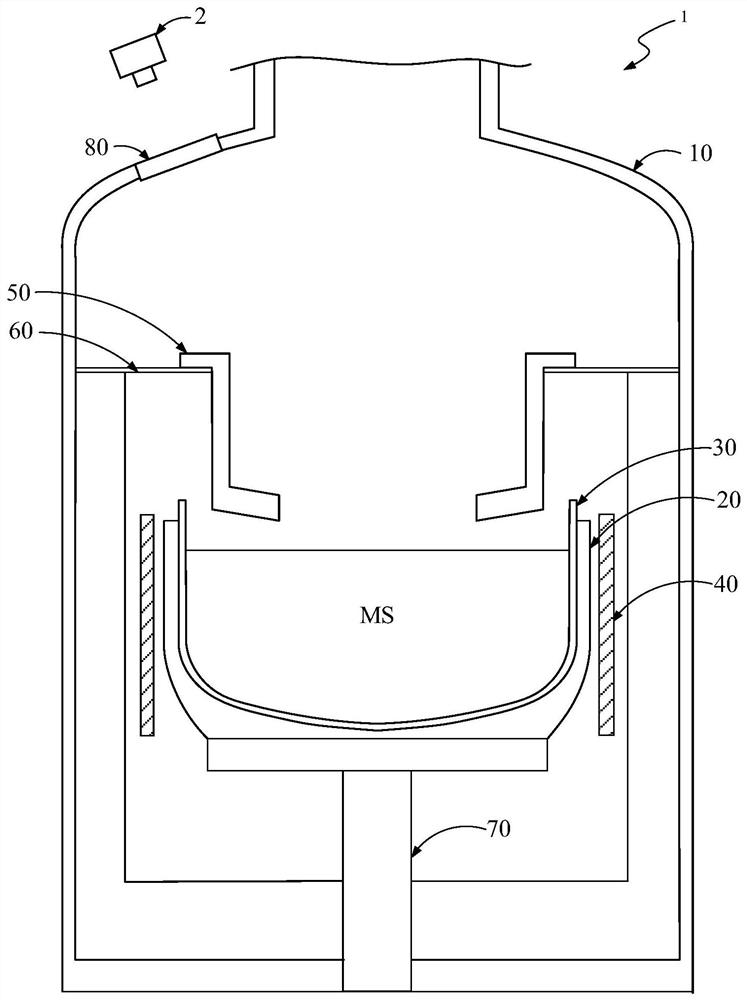

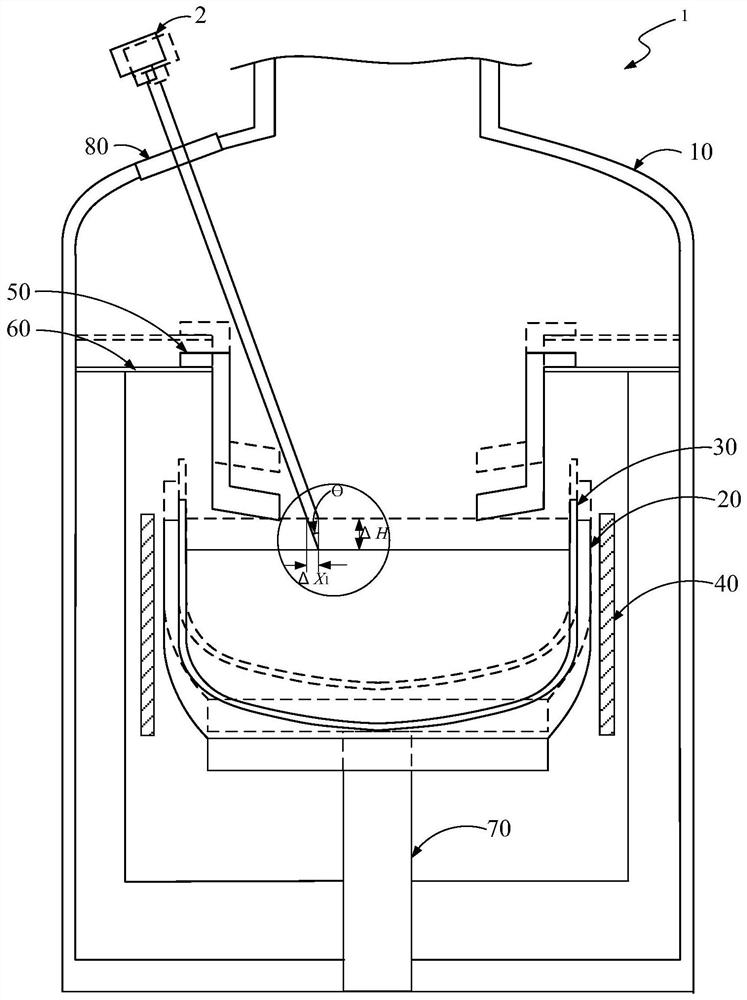

[0029] see figure 1 , which shows a single crystal furnace 1 capable of realizing the technical solution of the embodiment of the present invention, the single crystal furnace 1 may include: a furnace body 10, a heating device and a pulling device are arranged in the furnace body 10; the heating device includes a graphite crucible 20 , a quartz crucible 30 and a heater 40, etc., wherein the quartz crucible 30 is used to contain silicon raw materials, such as polysilicon. The silicon raw material is heated and melted into the melt MS in the quartz crucible 30 , the graphite crucible 20 is wrapped on the outside of the quartz crucible 30 to provide support for the quartz crucible 30 during the heating process, and the heater 40 is arranged on the outside of the graphite crucible...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com