Desizing method for glass fiber cloth with low expansion coefficient

A glass fiber cloth, low expansion coefficient technology, applied in the continuous processing of textile materials, equipment configuration for processing textile materials, heating/cooling fabrics, etc., can solve problems such as loss of tensile strength performance of glass fiber cloth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

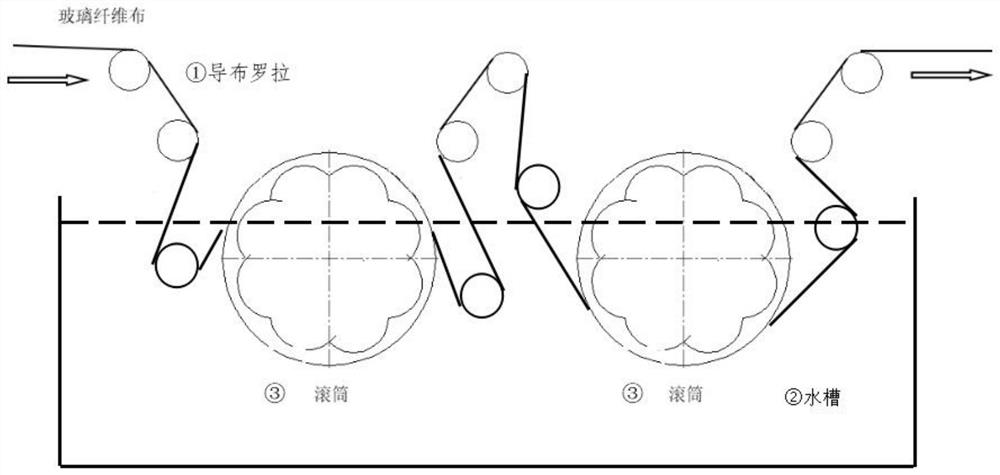

[0026] Such as Figure 1-2 Shown, a kind of low expansion coefficient glass fiber cloth desizing method of the present invention, comprises the following steps:

[0027] Step 1: Prepare the glass fiber gray cloth, the glass fiber cloth enters the water tank through the guide roller, and the organic matter on the surface of the glass fiber gray cloth is dissolved in hot water;

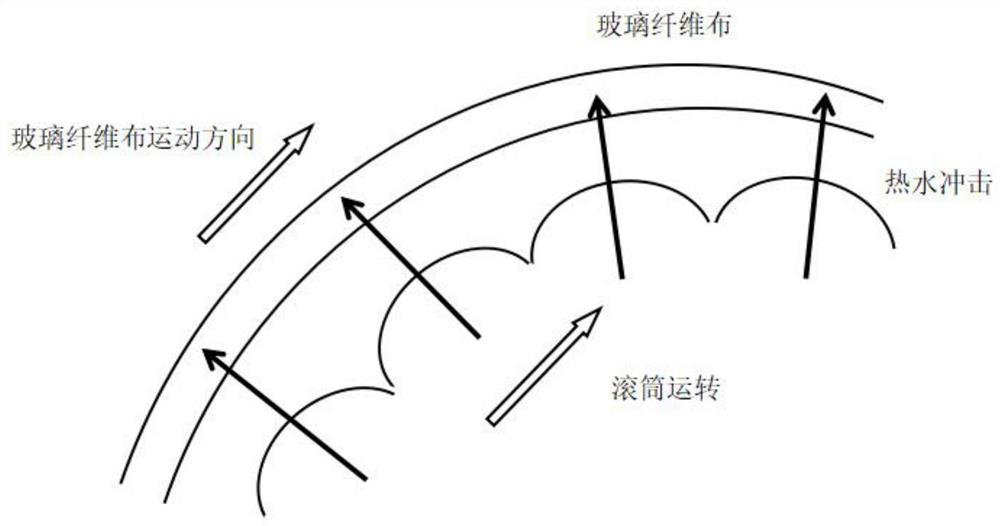

[0028] Step 2: Drum washing, the glass fiber gray cloth enters the water tank through the guide roller and is transported on the outer surface of the drum. The drum runs at a high speed driven by the motor to further impact the organic matter in the glass fiber gray cloth;

[0029] Step 3: Drying the glass fiber gray cloth, drying the glass fiber cloth after drum washing, removing the surface moisture of the glass fiber gray cloth, and winding the glass fiber cloth onto the desizing roller;

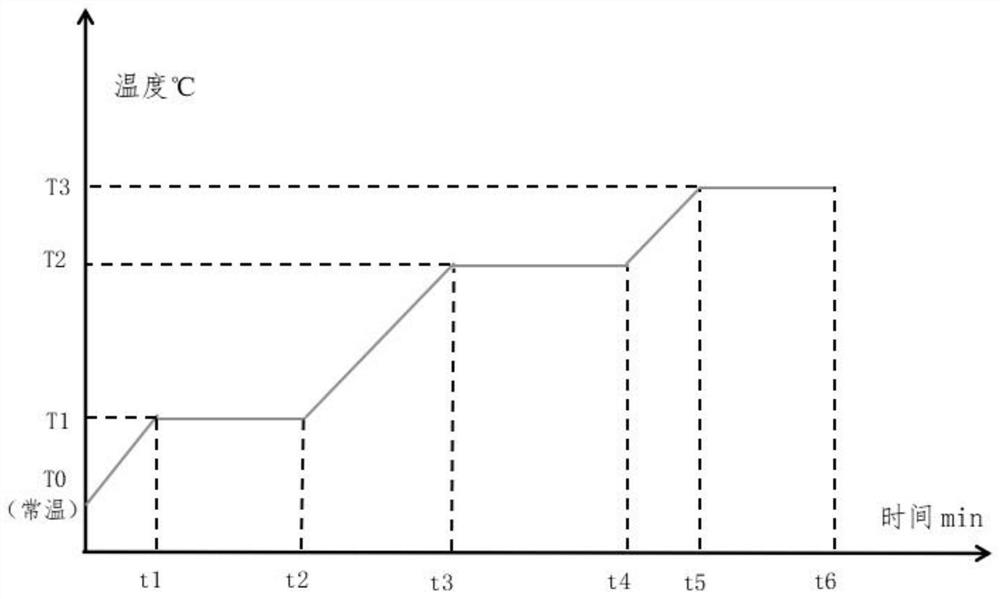

[0030] Step 4: BH sintering, the glass fiber gray cloth on the desizing roller is placed in a BH sintering furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com