Small-size transcatheter artificial heart valve and preparation method thereof

An artificial heart valve, small-sized technology, applied in medical science, tissue regeneration, prosthesis, etc., can solve the problems of increasing the size of the delivery, increasing the hardness of the valve, increasing the elastic modulus, etc. Effect of reduction and small conveying size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

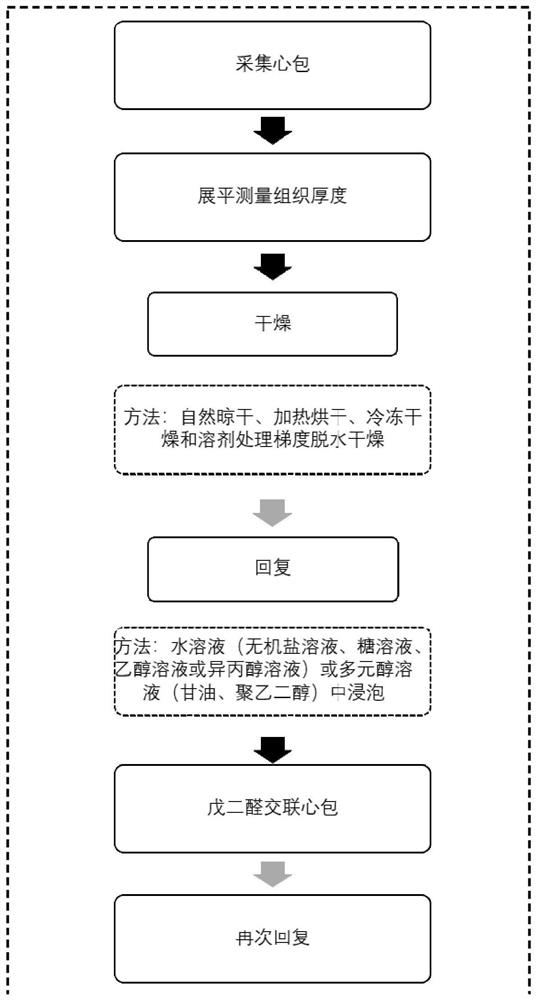

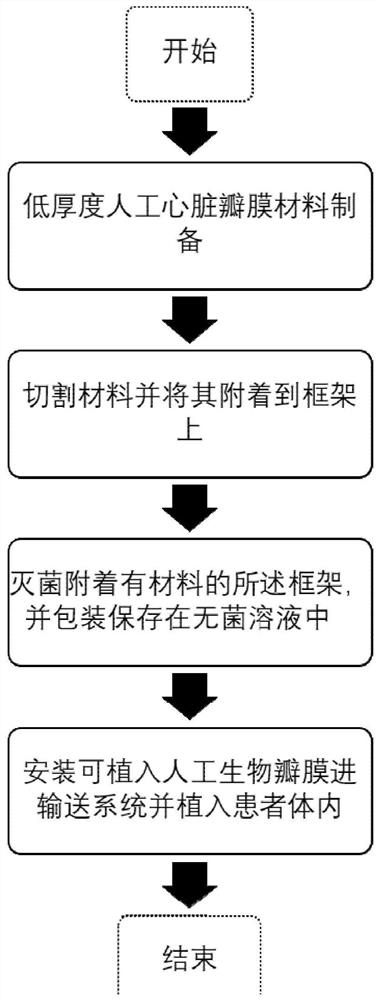

[0037] A preferred embodiment of the present invention provides a method for preparing a small-sized transcatheter artificial heart valve, and the specific steps are as follows:

[0038] Take fresh porcine pericardium, spread and fix it on a plastic plate, and dry it naturally. After 3 hours of drying, the film becomes transparent, and its thickness is less than 30% of the initial thickness. Then it is placed in glycerin solution for 3 weeks, and then placed In sterile normal saline for 1 week, its thickness increased, but less than the initial thickness, and then cross-linked using 0.625 wt% glutaraldehyde aqueous solution containing 25 wt% glycerin, the cross-linking time was 1 week, and the cross-linking was completed Afterwards, the valve was placed in glycerol solution for 3 weeks, and the leaflet tissue was obtained, the thickness of which was reduced by more than 25% compared with that of the pericardial tissue directly subjected to cross-linking treatment, and the mecha...

Embodiment 2

[0040] A preferred embodiment of the present invention provides a method for preparing a small-sized transcatheter artificial heart valve, and the specific steps are as follows:

[0041]Take fresh porcine pericardium, spread and fix it in the middle of a plastic plate, and freeze-dry it. After drying for 6 hours, its thickness is less than 20% of the original thickness, and then put it in glycerol solution for 3 weeks, and then put it in sterile normal saline 1 week, the thickness increased, but less than the initial thickness, then cross-linked using 0.625 wt% glutaraldehyde aqueous solution containing 25 wt% glycerin, the cross-linking time was 1 week, after the cross-linking was completed, the valve was placed in glycerin After 3 weeks in the solution, the valve leaflet tissue was obtained, the thickness of which was reduced by more than 30% compared with that of the pericardial tissue directly subjected to cross-linking treatment, and the mechanical properties and elastic m...

Embodiment 3

[0043] A preferred embodiment of the present invention provides a method for preparing a small-sized transcatheter artificial heart valve, and the specific steps are as follows:

[0044] Take fresh bovine pericardium, spread and fix in the middle of a plastic plate, freeze-dry, after drying for 6 hours, its thickness is less than 10% of the original thickness, then put it in glycerol solution for 3 weeks, then put it in sterile normal saline 1 week, the thickness increased, but less than the initial thickness, then cross-linked using 0.625 wt% glutaraldehyde aqueous solution containing 25 wt% glycerin, the cross-linking time was 1 week, after the cross-linking was completed, the valve was placed in glycerin After 3 weeks in the solution, the leaflet tissue was obtained, the thickness of which was reduced by more than 50% relative to the thickness of the pericardial tissue directly subjected to cross-linking treatment, and the mechanical properties and elastic modulus had no sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com