Desert buried pipeline monitoring system and method based on optical fiber vibration and temperature test

A buried pipeline and optical fiber vibration technology, which is applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of signal feature processing and low accuracy of monitoring signals, so as to improve accuracy and positioning accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

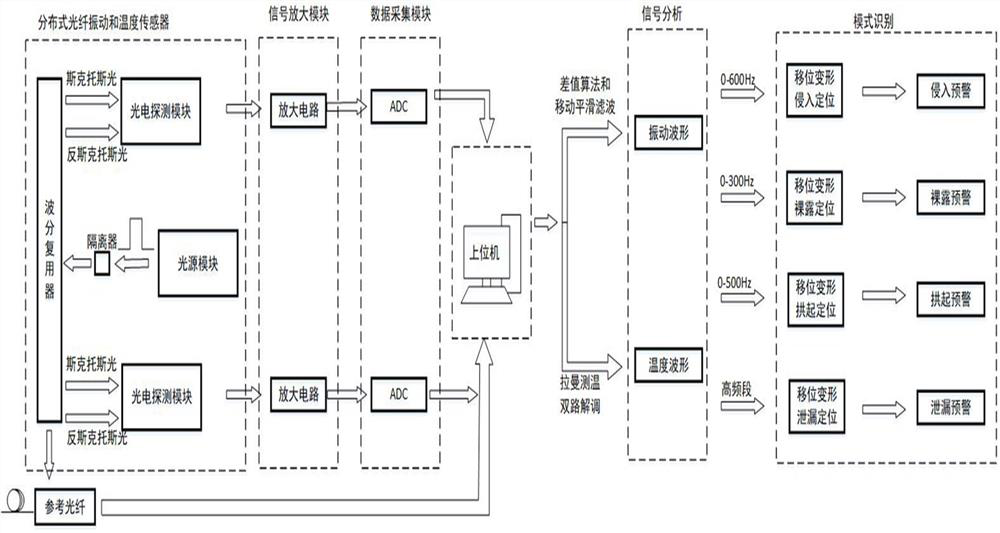

[0054] In this example, if figure 1 As shown, a desert buried pipeline information monitoring system based on distributed optical fiber vibration and temperature testing, the system includes data acquisition module, signal amplification module, signal acquisition module, signal analysis module, host computer, reference optical fiber and pattern recognition module. The signal acquisition module is connected with the reference optical fiber and the signal amplification module respectively; the signal amplification module is connected with the data acquisition module; the host computer is respectively connected with the data acquisition module and the reference optical fiber; the signal analysis module is connected with the host computer; the pattern recognition module is connected with the signal analysis module .

[0055] In this embodiment, the signal acquisition module includes a wavelength division multiplexer, an isolator, a light source module and two photoelectric detect...

Embodiment 2

[0078] In this embodiment, a desert buried pipeline information monitoring method based on distributed optical fiber vibration and temperature is carried out based on the monitoring system provided in Embodiment 1, which specifically includes the following steps:

[0079] S1, when the system enters the working state, the host computer respectively obtains the vibration signal detected by the distributed optical fiber vibration sensor and the temperature signal detected by the distributed optical fiber temperature sensor;

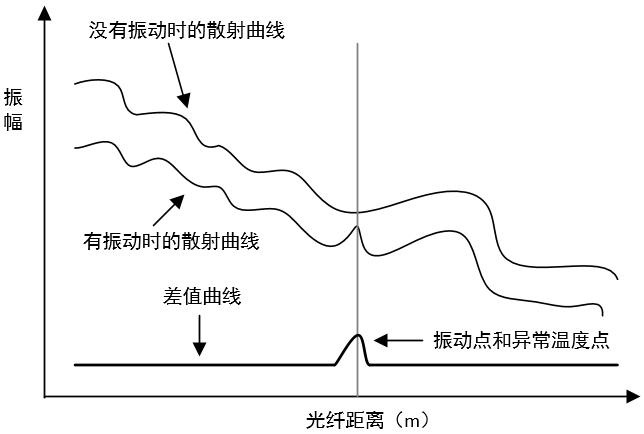

[0080]S2, the upper computer uses the difference algorithm to perform differential processing on the original scattering curve in the vibration signal to obtain the initial light intensity change range result, and uses the filtering algorithm to smooth the difference curve to remove redundant noise in the vibration signal and obtain the vibration source location value;

[0081] S3. According to the spontaneous Raman scattering effect technology and optical t...

Embodiment 3

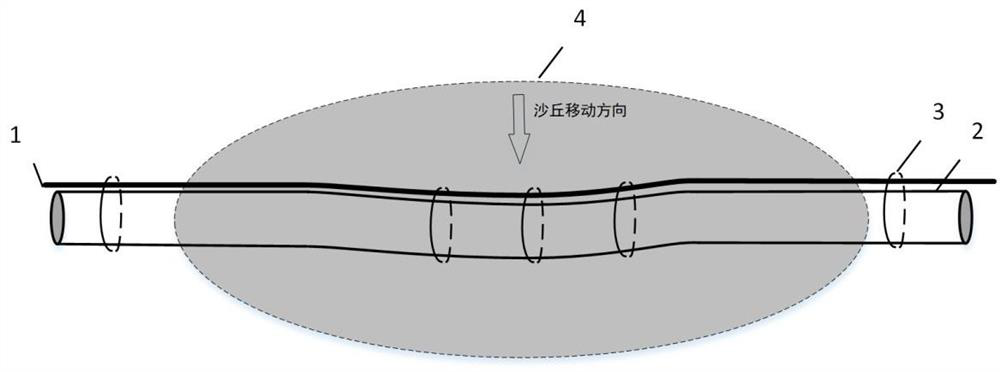

[0161]This embodiment is implemented based on Embodiment 1 and Embodiment 2. In this embodiment, distributed optical fiber vibration and temperature sensors can be used to locate the displacement and deformation in the pipeline desert.

[0162] Due to the movement of sand dunes, the pipeline will be displaced and deformed, mainly causing the transverse and longitudinal buckling deformation of the pipeline. At this time, fluid-solid coupling vibration will occur inside the pipeline. Further, the vibration will cause the refractive index of the optical fiber to change, and cause the return light intensity change. Since the change range of the light intensity in the vibrating area is stronger than that in the non-vibrating area, the light intensity change range is used as the basis for vibration location. The monitoring system and monitoring method use the difference algorithm to perform differential processing on the collected original scattering curve to obtain the initial ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com