Safe and energy-saving flat heat pipe air-cooled fuel cell stack and heat management method

A technology of fuel cell stacks and flat heat pipes, applied in fuel cells, secondary batteries, circuits, etc., can solve problems such as high parasitic power and uneven battery temperature, reduce internal resistance, reduce volumetric power density, and save size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

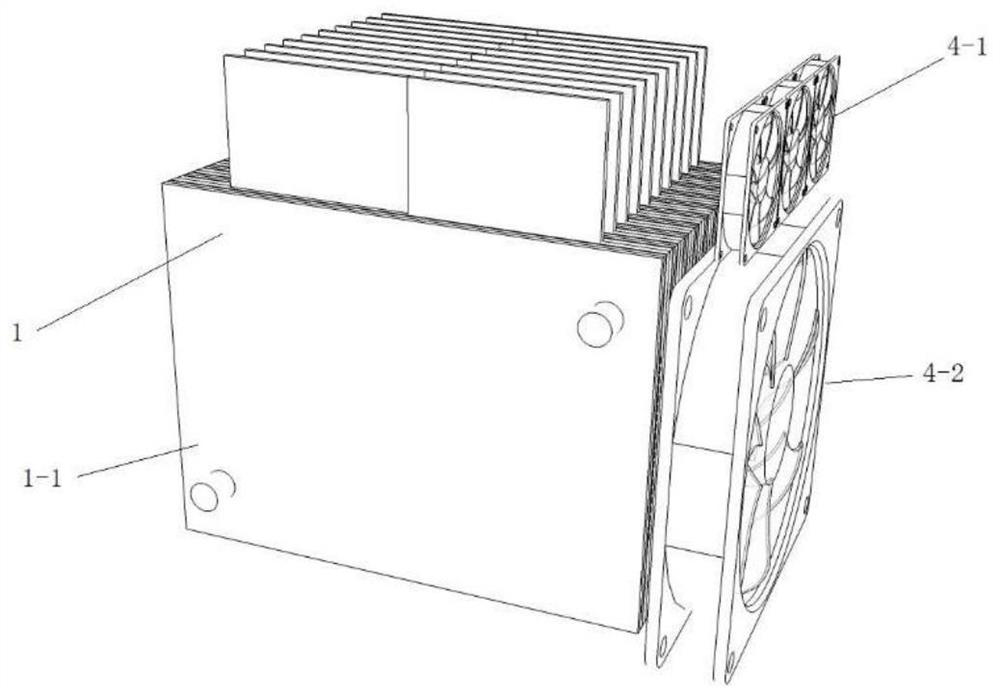

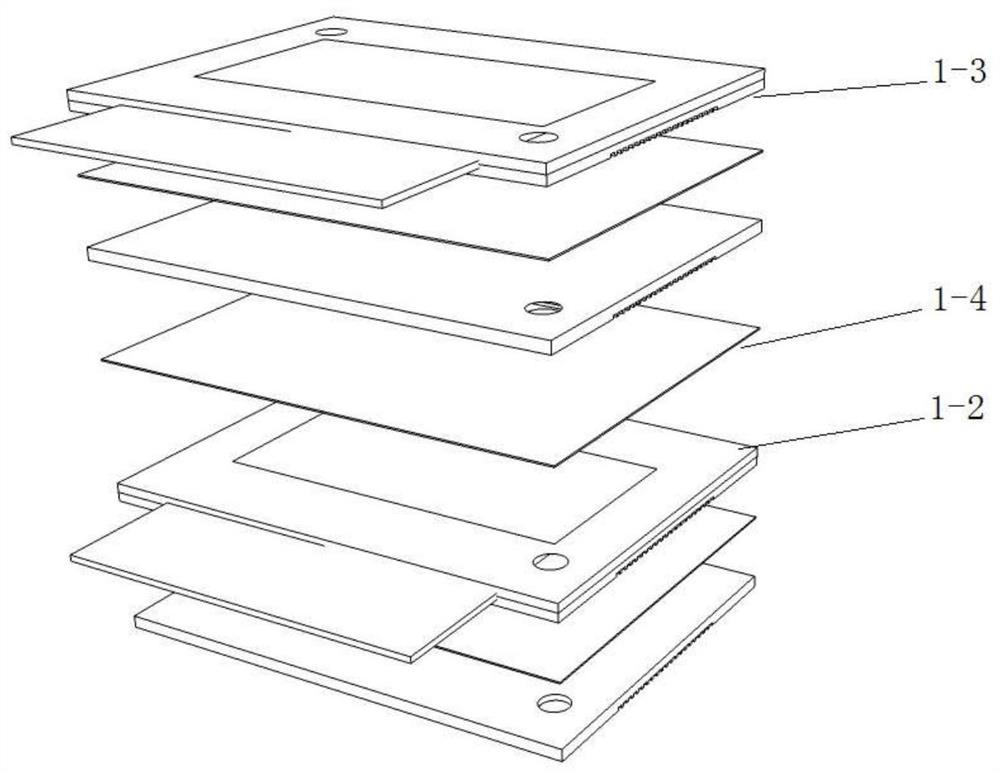

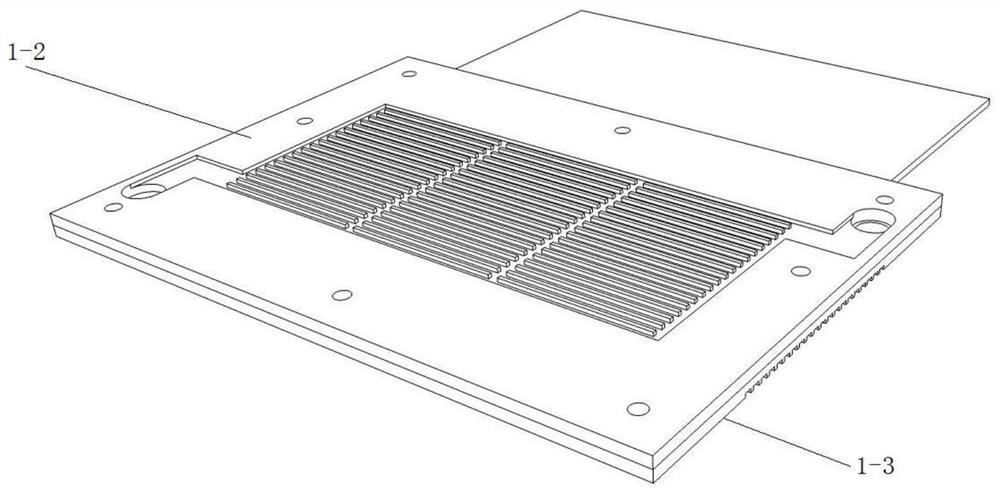

[0032] Such as Figure 1-3 As shown, this implementation case is a safe and energy-saving flat-plate micro-heat pipe air-cooled fuel cell stack, which is composed of a fuel cell stack 1 , a micro-heat pipe array 2 and a fan 4 . The fuel cell stack 1 includes two end plates 1-1, a current collector, multiple membrane electrodes 1-4 and multiple sets of bipolar plates, and the multiple membrane electrodes 1-4 and bipolar plates are arranged alternately. Part of the bipolar plate is attached to the micro heat pipe array 2 to form a bipolar plate with the micro heat pipe array, and part of the bipolar plate is not attached to the heat pipe and formed into a single plate. The bipolar plate with the micro heat pipe array 2 is composed of a plurality of anode plates 1-2 and cathode plates 1-3 attached to the micro heat pipe array 2 in the middle, and the micro heat pipe array 2 is attached to the anode plate 1-2 and the cathode plate 1 -3 in the middle, and closely arranged together...

Embodiment 2

[0035] In this embodiment, a fuel cell stack using air-cooled micro heat pipe arrays for thermal management, on the basis of Embodiment 1, additional fins 3 are added.

[0036] Such as Figure 4 As shown, in order to increase the heat exchange area, the protruding part of each of the micro heat pipe arrays 2 is attached to the upper fin 3 with thermal silica gel, and the heat is transferred from the fin 3 through the work of the cooling fan 4-1 installed above the fin 3 The inside of the battery is taken away, which has the effect of cooling the fuel cell.

Embodiment 3

[0038] In this embodiment, a fuel cell stack using air-cooled micro heat pipe arrays for thermal management, on the basis of the structure of embodiment 1 or embodiment 2, the micro heat pipe array 2 not only includes the inline micro heat pipe array 2, but also includes An L-shaped micro heat pipe array 2, and an electric heating chip 5 is arranged on the L-shaped micro heat pipe array 2.

[0039] Such as Figure 5 As shown, several groups of bipolar plates are spaced apart, and an L-shaped micro heat pipe array 2 is attached between the anode plate 1-2 and the cathode plate 1-3, or part of the inline micro heat pipe array 2 is replaced by an L-shaped micro heat pipe array2. The electric heating sheet 5 is attached to the bent portion of the end of the L-shaped micro heat pipe array 2 .

[0040] A fuel cell stack that utilizes micro heat pipe array air-cooling for heat management, using the above heat management system, a micro heat pipe array 2 is attached between the anod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydraulic diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com