Waste gas spray tower with tail gas purification treatment

A tail gas purification and treatment tower technology, applied in the field of spray towers, can solve the problems of lack of tail gas purification structure, lack of waste water treatment structure, lack of particulate matter detection structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

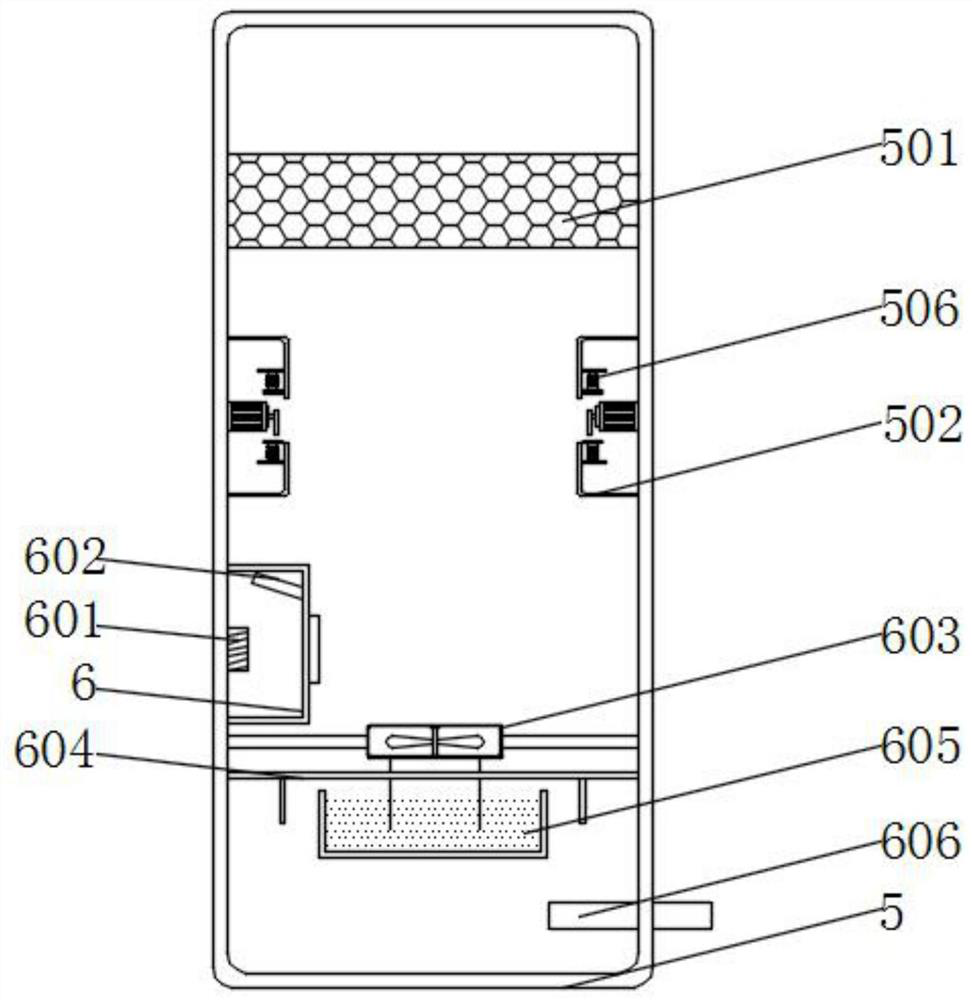

[0042] Example 2: see image 3 and Figure 4 , an embodiment provided by the present invention: a waste gas spray tower with tail gas purification treatment, the inner wall of the purification tower 5 is equipped with an activated carbon net 501, and the inner wall of the purification tower 5 is equipped with an igniter 502, and the igniter 502 is located on the activated carbon Below the net 501, a motor 503 is installed on the inner wall of the igniter 502, a cam 504 is installed on the output end of the motor 503, a fixed plate 505 is installed on the inner wall of the igniter 502, and a No. 1 spring 506 is installed on the bottom of the fixed plate 505. A flint 507 is installed at the bottom of the 506, a signal receiver 601 is installed on the inner wall of the protective case 6, an inclined laser transmitter 602 is installed on the inner wall of the protective case 6, a sealing plate is installed on the inner wall of the purification tower 5, and the top of the sealing p...

Embodiment 3

[0043] Example 3: See Figure 8 , an embodiment provided by the present invention: a waste gas spray tower with tail gas purification treatment, a flow detector 401 is installed on the outer wall of the connecting pipe 4, a rotating rod 402 is installed through the inner wall of the connecting pipe 4, and the rotating rod 402 Blades 403 are installed around the outer wall of the rotating rod 402, a reflector 404 is installed on the outer wall of the rotating rod 402, a support plate is installed on the inner wall of the flow detector 401, a processor 405 is installed on the top of the support plate, and an infrared signal transmitter is installed on the inner wall of the processor 405. An infrared signal receiver is installed on the inner wall of the processor 405, and the infrared signal receiver is located on one side of the infrared signal transmitter. The purified exhaust gas passes through the connecting pipe 4, and then the flow detector 401 detects the flow rate of the e...

Embodiment 4

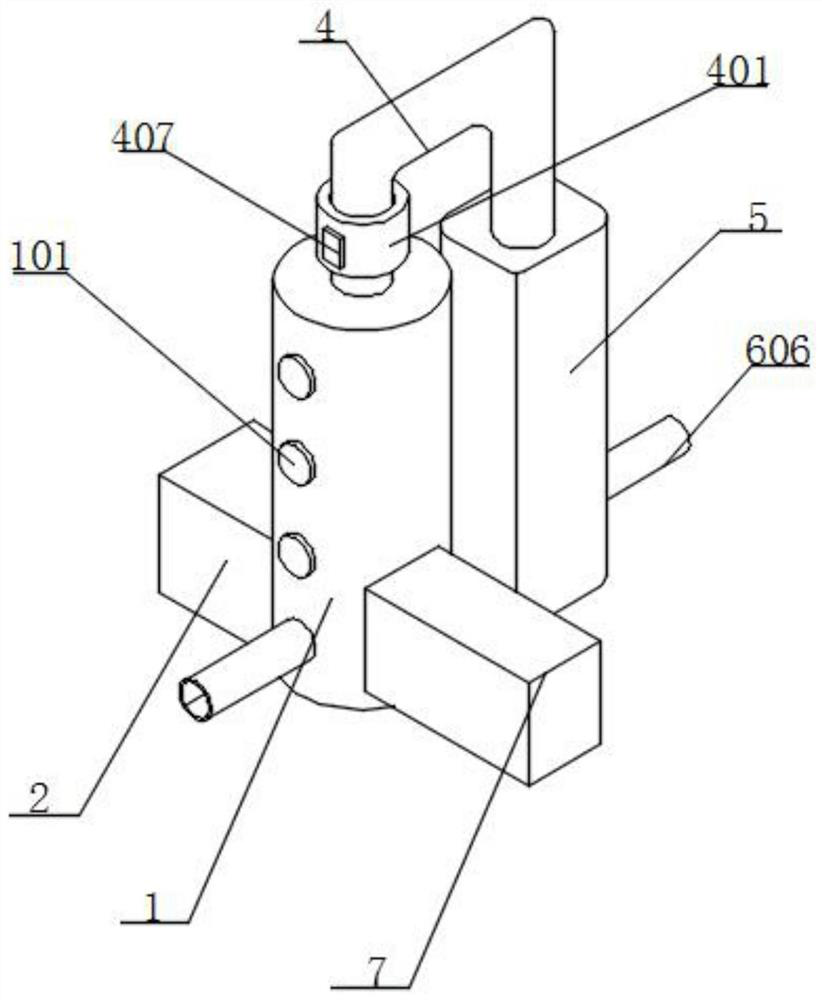

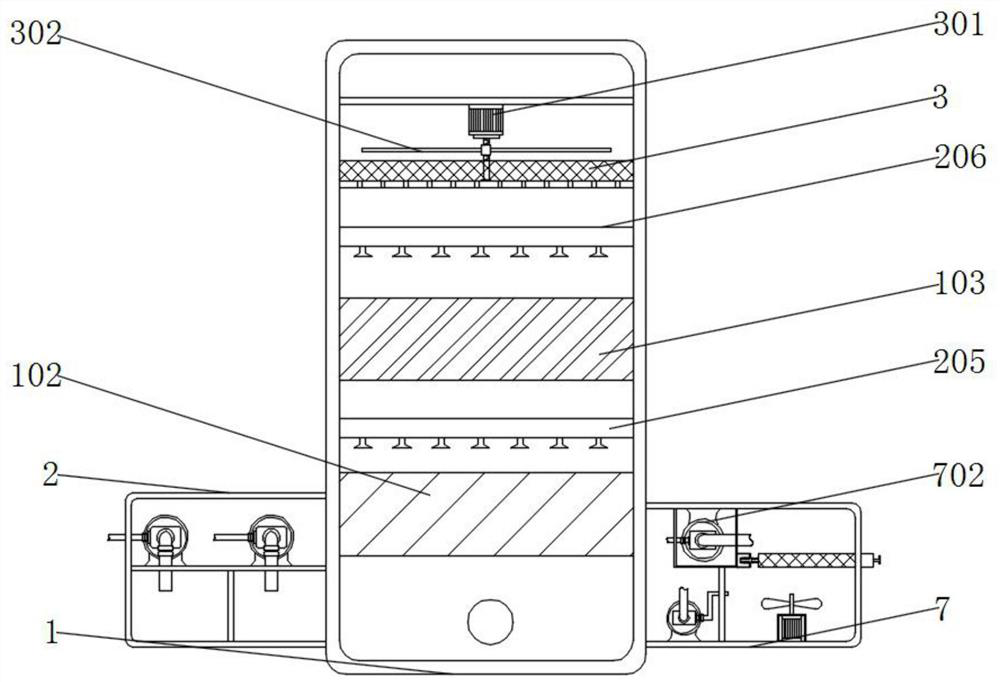

[0044] Example 4: See figure 1 , figure 2 and Figure 5 , an embodiment provided by the present invention: a waste gas spray tower with tail gas purification treatment, No. 1 purification block 102 is installed on the inner wall of the treatment tower 1, No. 2 purification block 103 is installed on the inner wall of the treatment tower 1, and the second The No. 1 purification block 103 is located above the No. 1 purification block 102. A plurality of portholes 101 are installed on the outer wall of the treatment tower 1. A No. 2 box 201 is installed on the inner bottom wall of the feed box 2. A No. 1 water pump 202 is installed on the top of the No. 1 box 201. , the input end of the No. 1 water pump 202 extends into the inside of the No. 1 box 201, the output end of the No. 1 water pump 202 extends into the inside of the treatment tower 1, and the output end of the No. 1 water pump 202 is equipped with a spray pipe 205, and the feed box 2 No. 2 tank 203 is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com