Closed carbon brush grinding tool

A grinding tool and closed technology, applied in the field of closed carbon brush grinding tools, can solve problems such as the influence of the operating environment of the unit, overheating of carbon brushes, uneven grinding, etc., so as to reduce maintenance labor intensity, improve work efficiency and grinding accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

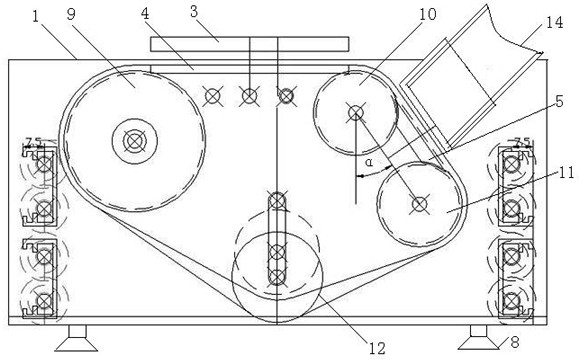

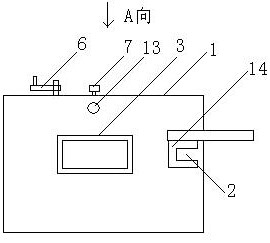

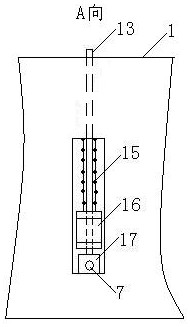

[0015] see figure 1 -3, the names of parts are as follows: cuboid dust collection box 1, carbon brush socket 2, flat grinding port 3, flat module 4, arc-shaped flat grinding module 5, crank handle 6, knob 7, suction cup feet 8, driving wheel 9. The first driven wheel 10, the second driven wheel 11, the third driven wheel 12, the guide rod bolt 13, the brush holder 14, the spring 15, the tension adjustment wheel 16, and the guiding and fixing block 17.

[0016] see figure 1 , figure 2 , the closed carbon brush grinding tool includes a dust box 1, and the inside of the dust box 1 has a driving wheel 9, a first driven wheel 10, a second driven wheel 11 and a third driven wheel 12 (both diameter The same), there are grooves on the surface of each driving wheel and driven wheel, which are used for fixing and abrasive belt transmission (equivalent to the belt in the pulley structure). A plane grinding module 4 is fixed between the driving wheel 9 and the first driven wheel 10. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com