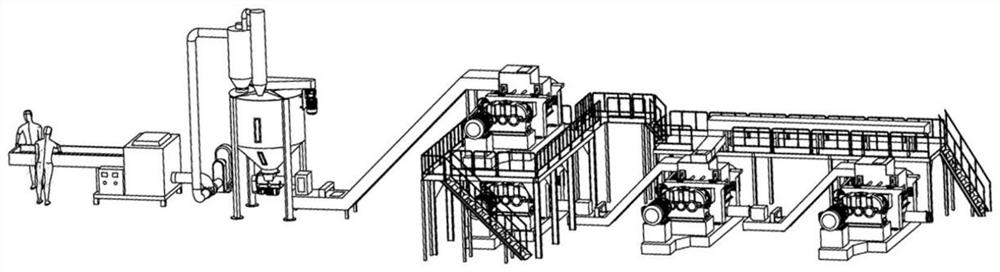

Polyurethane flexible foam low-temperature activation powder making device and method

A polyurethane soft foam, low temperature activation technology, applied in plastic recycling, mechanical material recycling, recycling technology and other directions, can solve the problems of inactive preparation of micropowder, inability to pulverize materials, temperature rise, etc., to ensure the quality of the working environment and production. The effect of efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

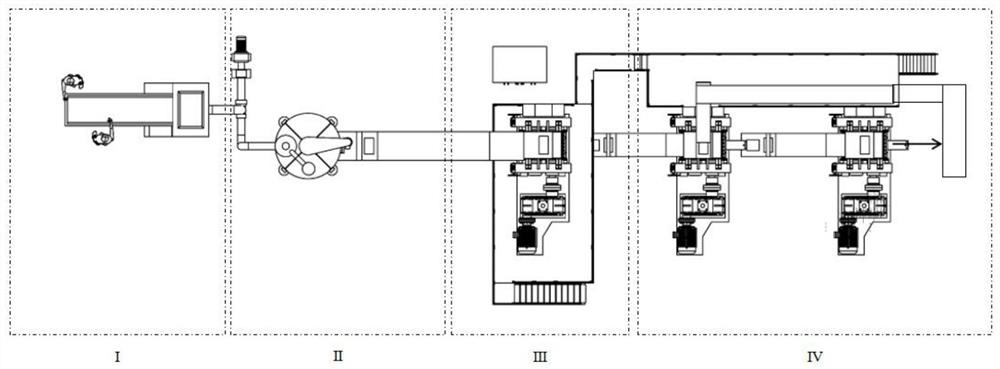

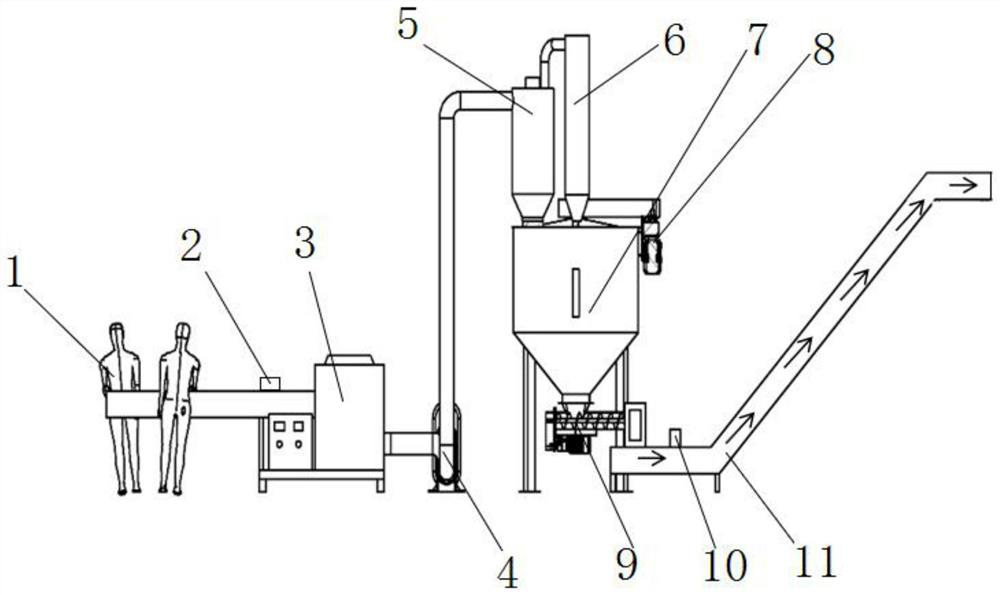

[0048] (1) Place the polyurethane flexible foam waste on the double-station feeding conveyor belt 1, and enter the residual material block making device for cutting after metal detection, and prepare the polyurethane flexible foam waste into small pieces with a side length of 10-100mm Cubes are then transported to the homogenization buffer silo 7 by the pneumatic feeder 4, waiting for the follow-up activation of the milling process;

[0049] (2) Enter the polyurethane soft foam small pieces in the homogenized buffer storage bin into the activated powder making unit through the lifting conveyor belt 11 to carry out the activated pulverizing process of the polyurethane flexible foam. The block is conveyed into the first double-roller strong shearing device 13, and then the material enters the second double-roller strong shearing device 13 by gravity for preliminary activation and pulverization, and the activated fine powder enters the second double-roller strong shearing device 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com