High-erosion-resistance screen pipe outer protective cover and method for reducing erosion damage risk of screen pipe

An outer protective cover, high anti-scour technology, used in earth-moving drilling, production fluids, wellbore/well components, etc., can solve the problem of difficult to locate the high-risk position of screen erosion damage, and enhance the screen of the whole well section. In order to improve the anti-erosion ability of the screen pipe, reduce the risk of erosion damage and enhance the anti-erosion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

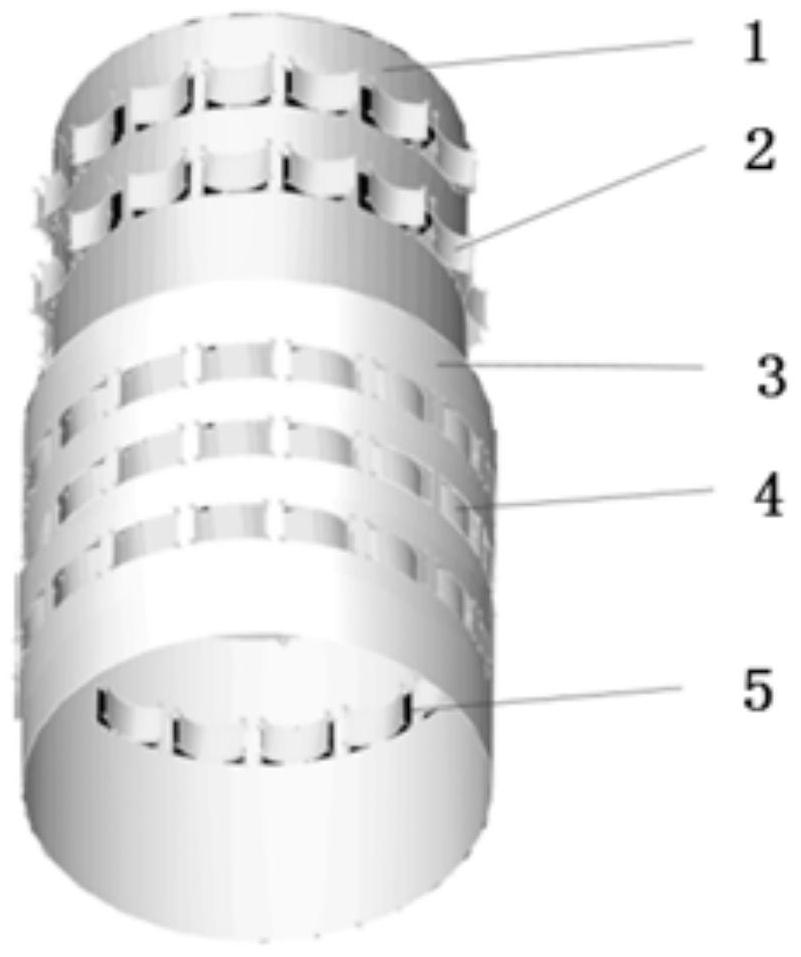

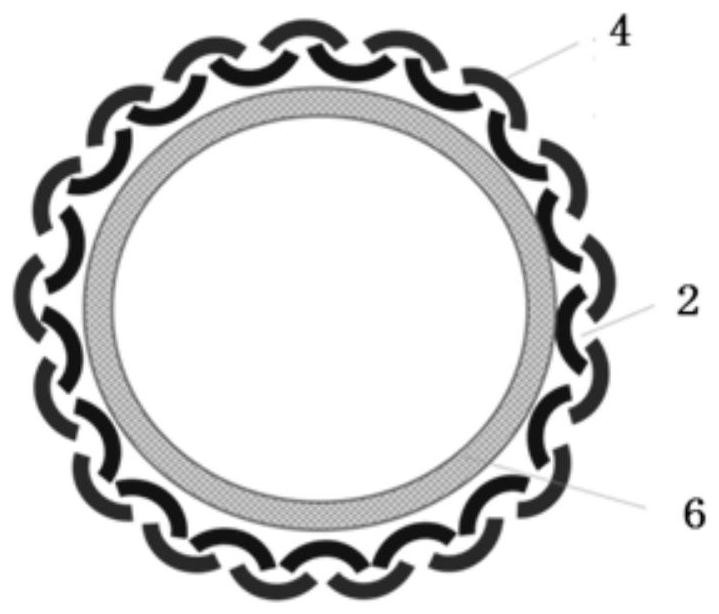

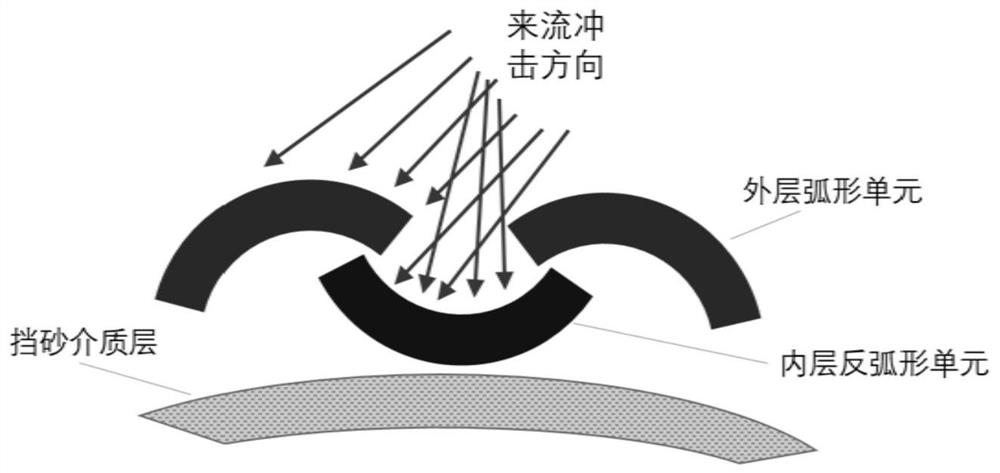

[0080] Such as figure 1 , figure 2 As shown, a high erosion-resistant screen outer protective cover, the outer protective cover includes an inner layer matrix 1 and an outer layer matrix 3 arranged together from the inside to the outside, and the inner layer matrix 1 and the outer layer matrix 3 are Both are provided with horizontally arranged arc-shaped punching slots, the arc-shaped punching slots 2 on the inner substrate and the arc-shaped punching slots 4 on the outer layer substrate are interlaced, and the arc directions of the arc-shaped punching slots are opposite.

[0081] The thickness of the inner substrate 1 is 0.4-0.6mm, the length of the arc-shaped punching seam is 50-10mm, the punching distance is 20-30mm, and the arc angle is controlled at 150-170°. The thickness of the outer substrate 3 is 0.5-0.8mm, the length of the arc-shaped punching seam is 50-10mm, the punching distance is 30-40mm, and the arc angle is controlled at 150-170°. The diameter of the inner...

Embodiment 2

[0084] A screen with high erosion resistance, the screen includes from the inside to the outside in sequence: a base pipe, the base pipe is provided with diversion holes communicating with the inside of the base pipe; an inner layer filter is sleeved on the outside of the base pipe; The outer layer filter set on the outside of the base pipe; the pre-fill layer between the inner layer filter screen and the outer layer filter screen; the outer protective cover of embodiment 1, the outer protective cover is set on the outer side of the outer layer filter screen, and the end fixed on the base tube.

Embodiment 3

[0086] The sand control completion method for reducing the risk of erosion damage by using the high erosion resistance screen of embodiment 2 includes:

[0087] S1: provide a high erosion resistance screen;

[0088] S2: Based on the heterogeneity of the inflow and sand production profiles displayed by porosity and rock density, identify the high-speed inflow and sand production positions and area lengths during the production process, and determine the high-speed inflow positions and areas in the production interval of oil and gas wells as a follow-up improvement Anti-erosion ability of the screen, and the target position to reduce the risk of erosion damage to the bottom hole screen;

[0089] The identification method of the high-speed inflow position and the area length of the oil and gas well production section is as follows:

[0090] Step 1: Obtain the porosity and rock density of the production section of the target well;

[0091] Step 2: Calculate the pseudo-inflow ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com