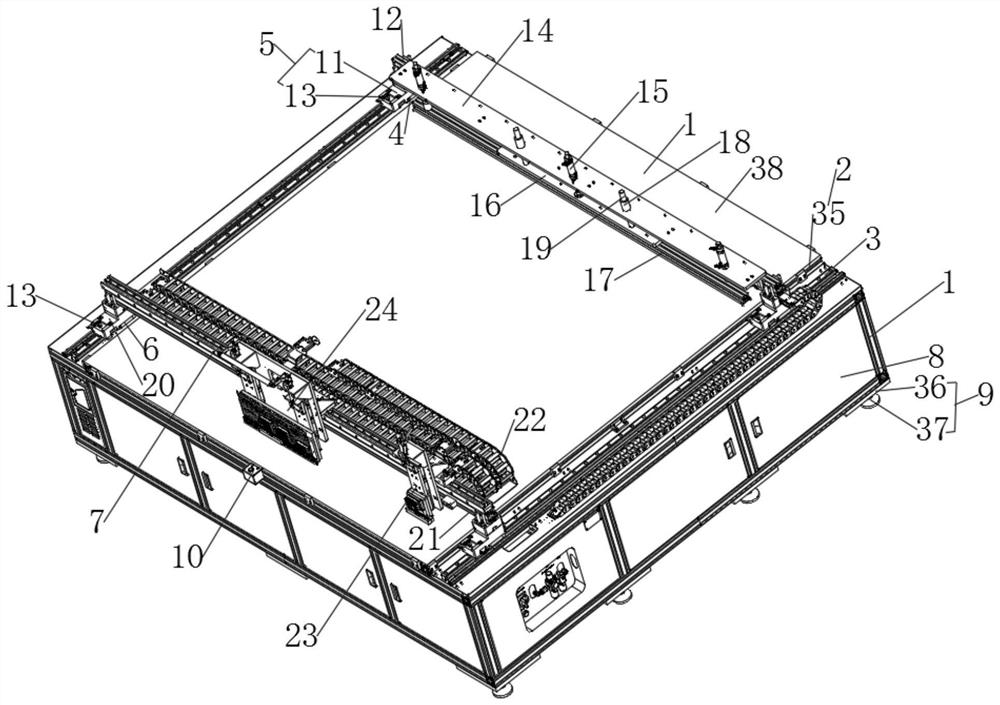

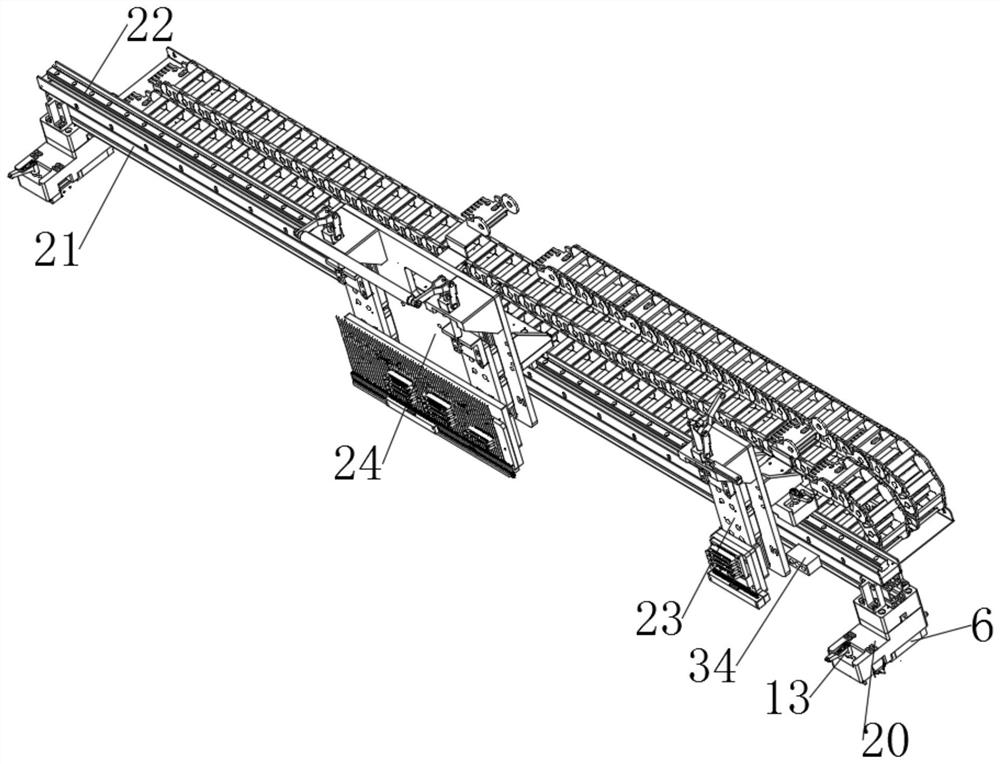

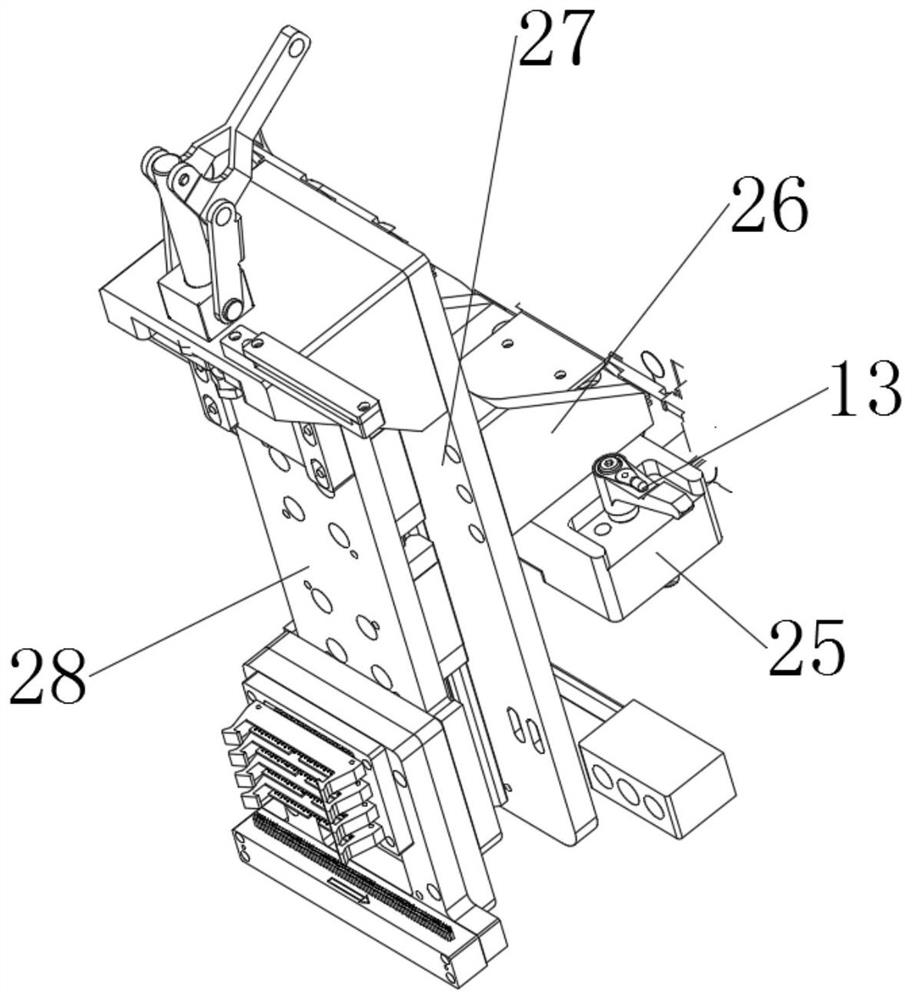

Electric appliance capacitive screen conduction detection equipment

A technology of conduction detection and capacitive screen, which is applied to parts, instruments, and measuring electronics of electrical measuring instruments, can solve problems such as low detection efficiency, low service life of capacitive screens, and inaccurate detection results, and reduce labor intensity , Stable operation and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] First of all, the original design intention of the present invention is explained. The capacitive touch screen technology uses the current induction of the human body to work. The capacitive touch screen is a four-layer composite glass screen. The inner surface and interlayer of the glass screen are each coated with a layer of ITO. The outermost layer is A thin layer of silica glass protective layer, the interlayer ITO coating is used as the working surface, four electrodes are drawn from the four corners, and the inner layer of ITO is the shielding layer to ensure a good working environment. During the production process of the electrical capacitance screen, it is necessary to Carry out conduction detection to ensure the service life of the capacitive screen. Most of the existing detection process is through manual detection. This method is low in efficiency and labor-intensive for workers. The detection device has a complex structure, high cost, low detection efficienc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com