Candy package surface defect quick detection method based on machine vision

A technology of machine vision and detection methods, applied in neural learning methods, instruments, computer parts and other directions, can solve the problems of low efficiency, high cost and low accuracy of manual detection, achieve rich distribution, reduce the generation of defective products, The effect of avoiding missed detection and false detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

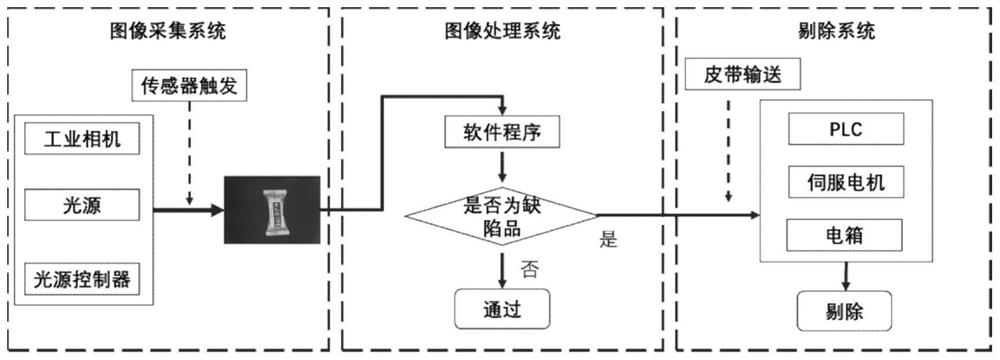

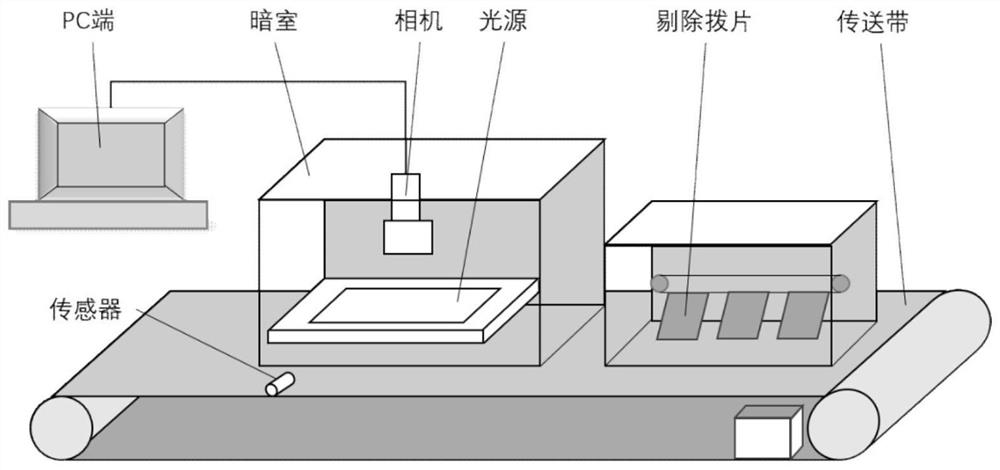

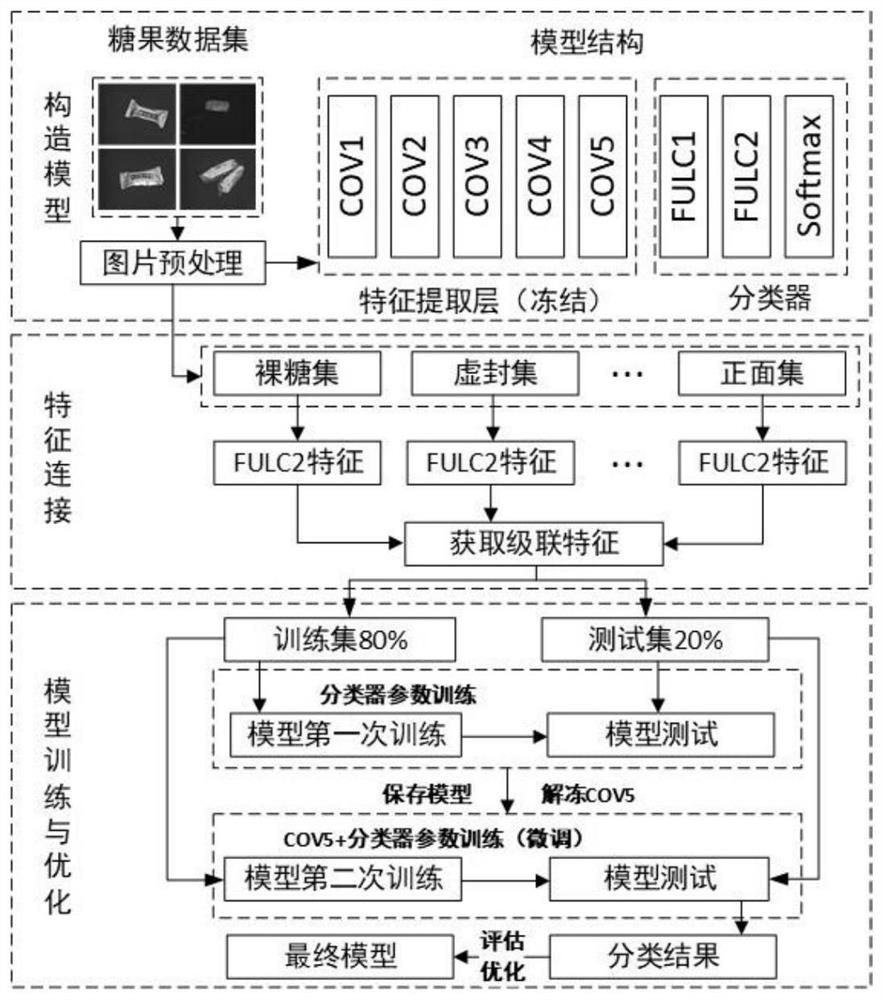

[0057] see figure 1 and figure 2 , a machine vision-based rapid detection method for candy packaging defects, the specific implementation steps are as follows:

[0058] Step 1: Image acquisition.

[0059] Specifically, after the candy is packaged from the production line, it enters the image acquisition unit through the conveyor belt, and arrives directly under the flat shadowless light source, triggering the infrared sensor, which sends a signal to the industrial camera to trigger the photo, and saves it in the camera memory.

[0060] Step 2: Image processing.

[0061] The image processing software automatically makes a judgment after receiving the picture in the memory of the processor. If it is judged to be unqualified, it will quickly transmit the defective product signal to the rejecting mechanism.

[0062] Step 3: Removal of defective products.

[0063] After receiving the defective product signal, the transmission signal is sent to the PLC, and the PLC controls the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com