Expanded polytetrafluoroethylene surgical isolating membrane and manufacturing process thereof

A technology of polytetrafluoroethylene and manufacturing process, which is applied in medical science, flat products, and other household appliances, etc., can solve the problems of poor surface flatness, lower product purity, and insufficient overall strength, and achieve safe use, high purity, and The effect of simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

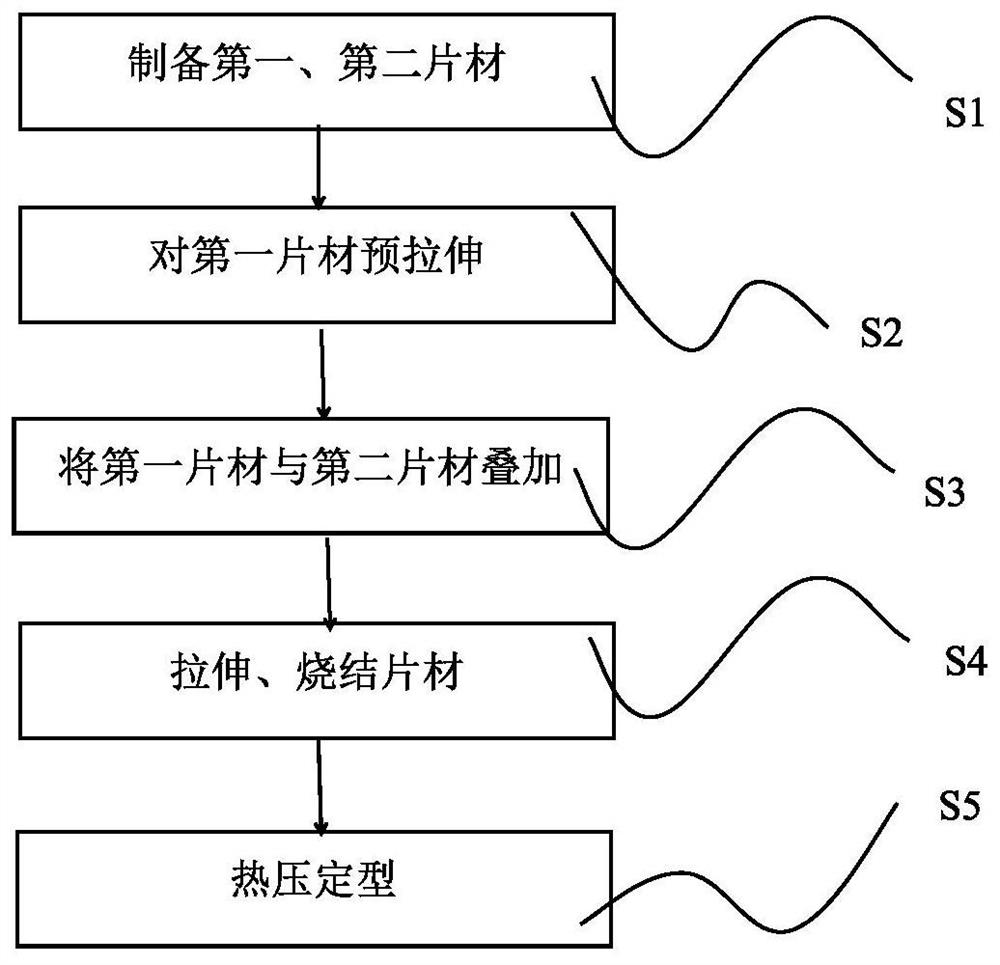

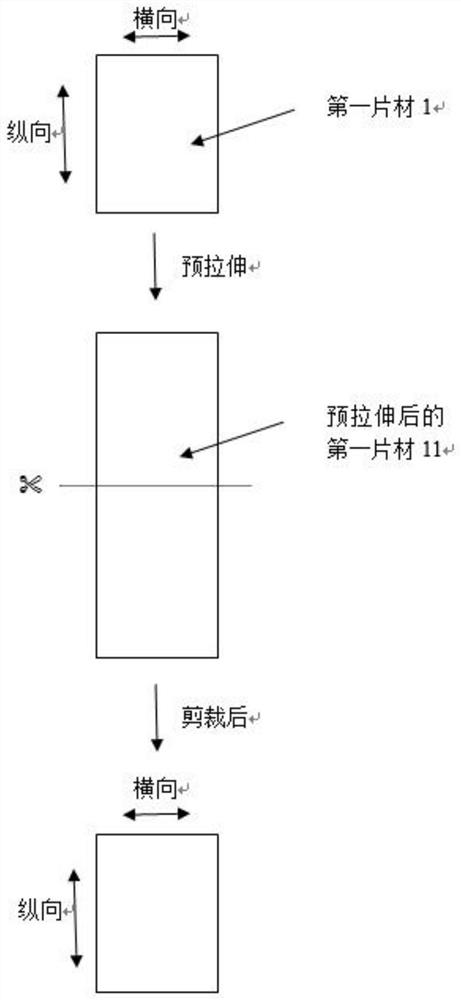

[0054] This embodiment provides a kind of preparation method of the double-layer expanded polytetrafluoroethylene surgical isolation membrane that adds antibacterial agent, and its steps are as follows:

[0055] S1, preparing the first sheet 1 and the second sheet 2, the specific steps are as follows:

[0056] S1.1, below 20°C, use polytetrafluoroethylene dispersion resin as raw material, add extrusion aid and antibacterial agent, the mass ratio is polytetrafluoroethylene dispersion resin: extrusion aid: antibacterial agent=100: (20~50 ): (1-5), mix evenly, heat up to 30-50°C, and let stand for 8-24 hours to ensure full penetration of extrusion aid;

[0057] S1.2, heat up the mixed resin in step S1.1 to 25°C-35°C, and preform it into a billet shape for easy extrusion;

[0058] S1.3, heating the mouth temperature of the extruder to 40-60°C, and then extruding the resin formed in step S1.2 to form a sheet of 1.5-2.5 mm;

[0059] S1.4, roll the sheet prepared in step S1.3 at 50...

Embodiment 2

[0078] The present embodiment provides a multilayer expanded polytetrafluoroethylene surgical isolation membrane with a silica gel interlayer adding an antibacterial agent, and the steps are as follows:

[0079] Steps S1, S2, S4 are exactly the same as steps S1, S2, S4 in embodiment 1; S3, S5 are respectively:

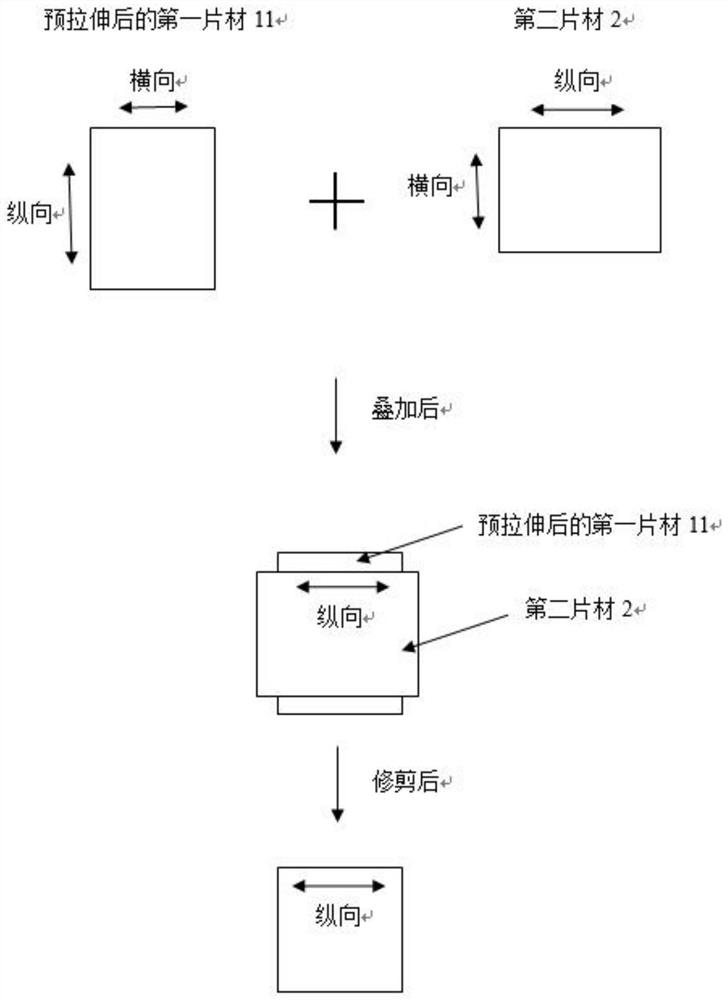

[0080] S3, stack the pre-stretched first sheet 11, the silicone sheet 4, and the second sheet 2 in sequence, wherein the pre-stretched first sheet 11 and the second sheet 2 are stacked in two directions. The longitudinal directions of the sheets are at an angle of 90° to each other, and then the three are regarded as a whole, and the overlapping parts are trimmed into squares or rectangles, including:

[0081] S3.1, placing the longitudinal direction of the pre-stretched first sheet 11 and the longitudinal direction of the second sheet 2 perpendicular to each other, superimposing them, and then cutting them into the same size;

[0082] S3.2, adding a silica gel sheet ...

Embodiment 3

[0085] The present embodiment provides a multi-layer expanded polytetrafluoroethylene surgical isolation membrane with polytetrafluoroethylene emulsion as an adhesive by adding an antibacterial agent, and the steps are as follows:

[0086] Steps S1, S2, S4, S5 are exactly the same as steps S1, S2, S4, S5 in embodiment 1; S3 comprises:

[0087] S3, taking one of the pre-stretched first sheets 11 and the second sheet 2 to be superimposed, the superposition direction ensures that the longitudinal directions of the two sheets are at an angle of 90° to each other, and then the two are regarded as a whole pair of overlapping Parts are trimmed into squares or rectangles, and an adhesive (PTFE emulsion 3 in this example) is used between the two sheets, specifically:

[0088] S3.1, placing the longitudinal direction of the pre-stretched first sheet 11 and the longitudinal direction of the second sheet 2 perpendicular to each other, superimposing them, and then cutting them into the sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com