Fuel gas pressure stabilizing type top-speed steam engine

A voltage-stabilizing, steam engine technology, applied in steam boilers, steam generation, steam boiler accessories, etc., can solve the problems of wasting manpower and resources, and achieve the effects of saving energy, protecting safety, and preventing dry burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

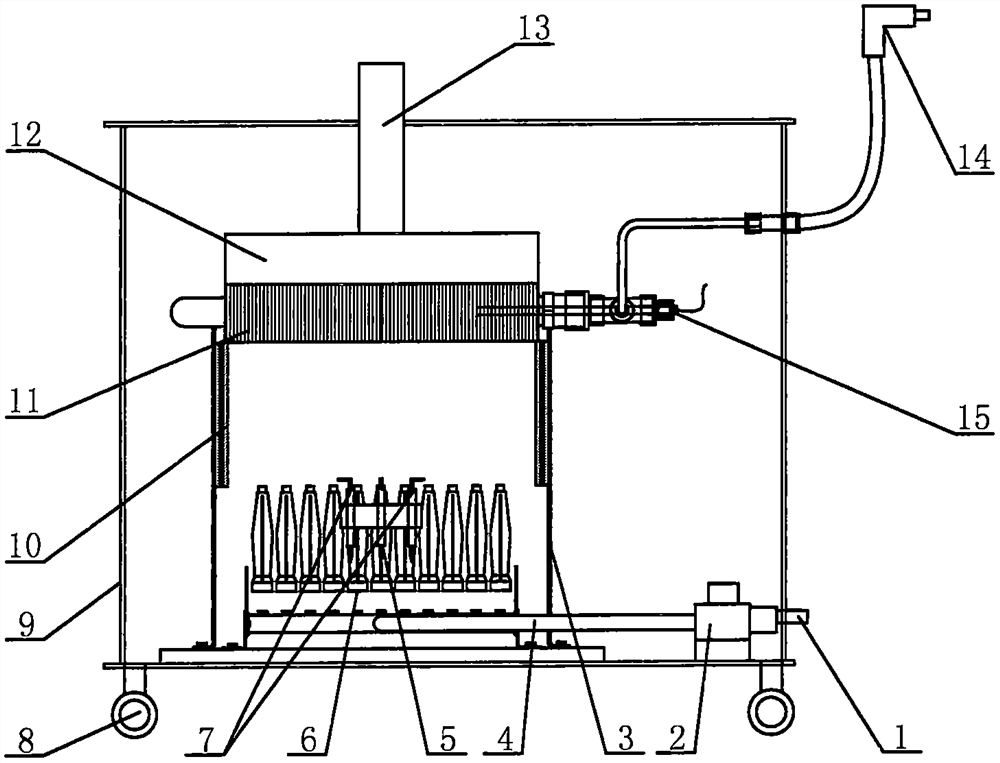

[0017] 17. The gas-fired pressure-stabilized extreme-speed steam engine will be further described below in conjunction with the accompanying drawings and examples.

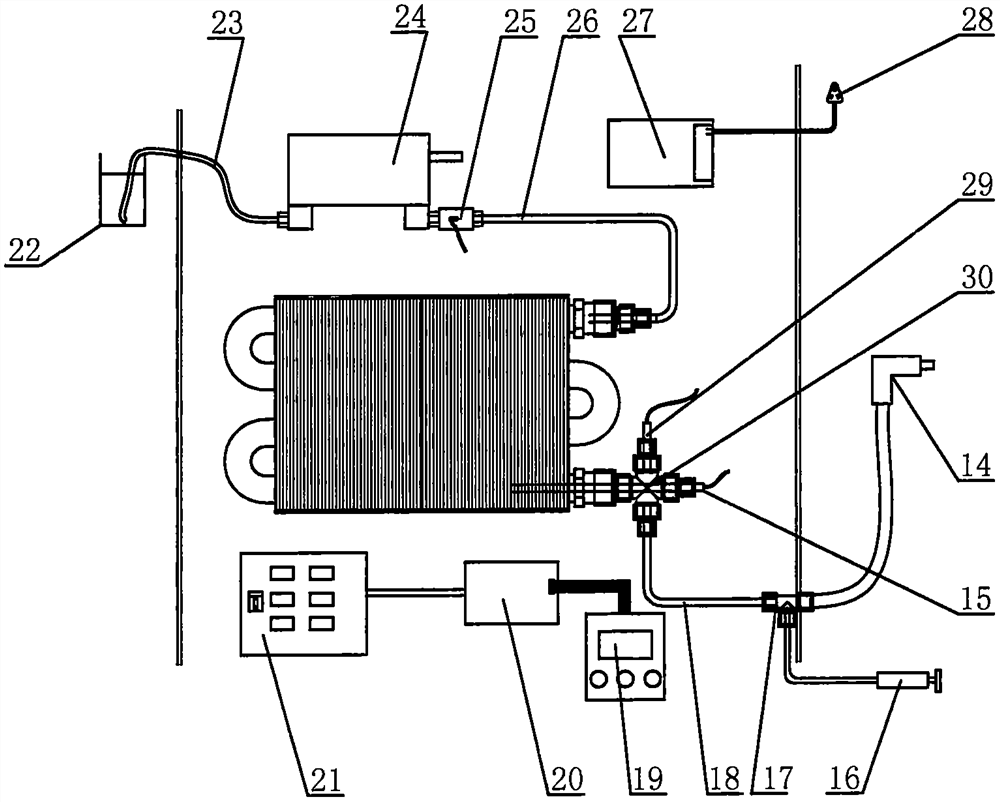

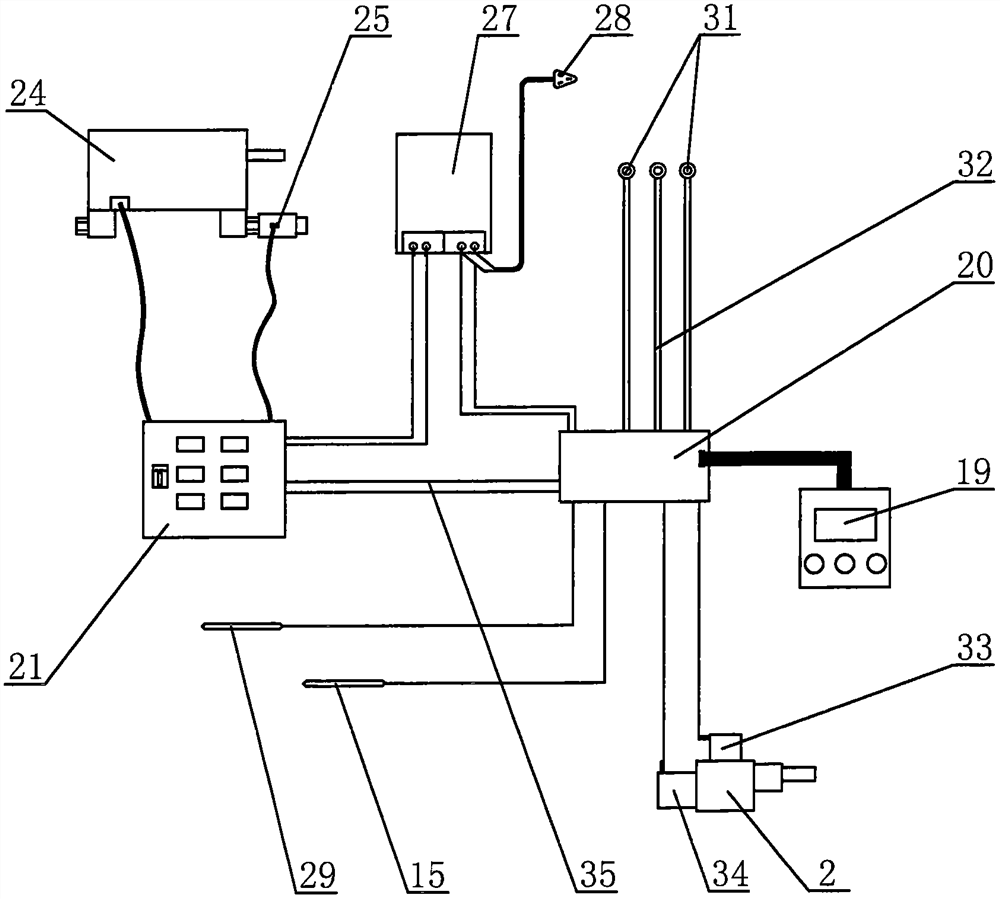

[0018] 18. See Figure 1-Figure 2 - image 3 The utility model relates to a gas-fired pressure-stabilized extreme-speed steam engine. Including the main body 9 of the extreme speed steam engine, its internal combustion chamber 3, the burner assembly 6 in the combustion chamber 3, the ignition needle 7, the ion induction needle 5, the combustion chamber 3 is a square structure, and its four sides are equipped with heat insulation materials 10 inside, The top of the combustion chamber 3 is equipped with an extremely fast steam generator 11, and the top of the extremely fast steam generator 11 is equipped with a smoke collection hood 12, and a smoke exhaust pipe 13 is installed above the smoke collection hood 12.

[0019] 19. The steam outlet of the ultra-fast steam generator 11 is connected with a four-way joint 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com