Manufacturing technology of heating module of solar heating room

A production process and solar energy technology, applied in the field of housing construction, can solve the problems of snow accumulation in winter, low construction efficiency, poor heat preservation, etc., and achieve the effect of improving house building efficiency, reducing house building cost and good heating effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

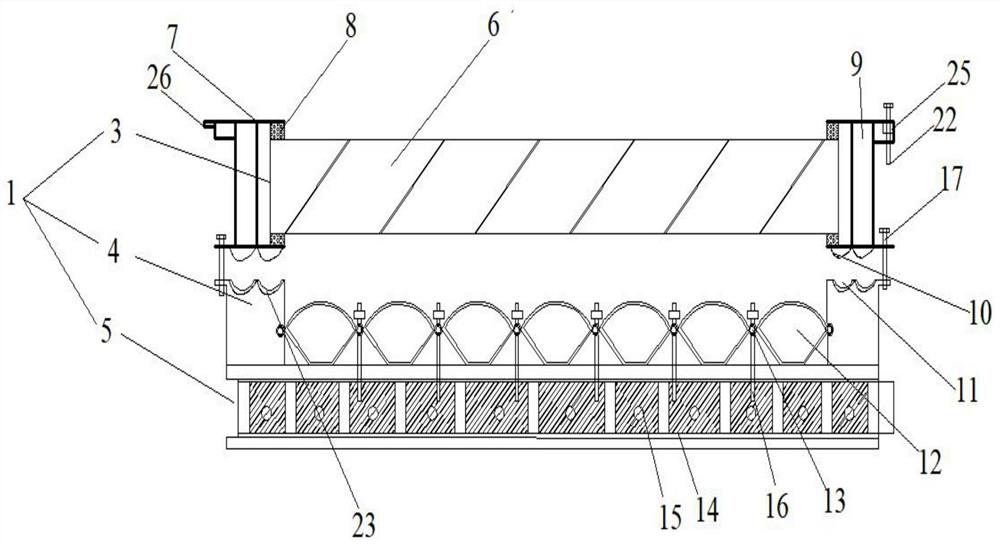

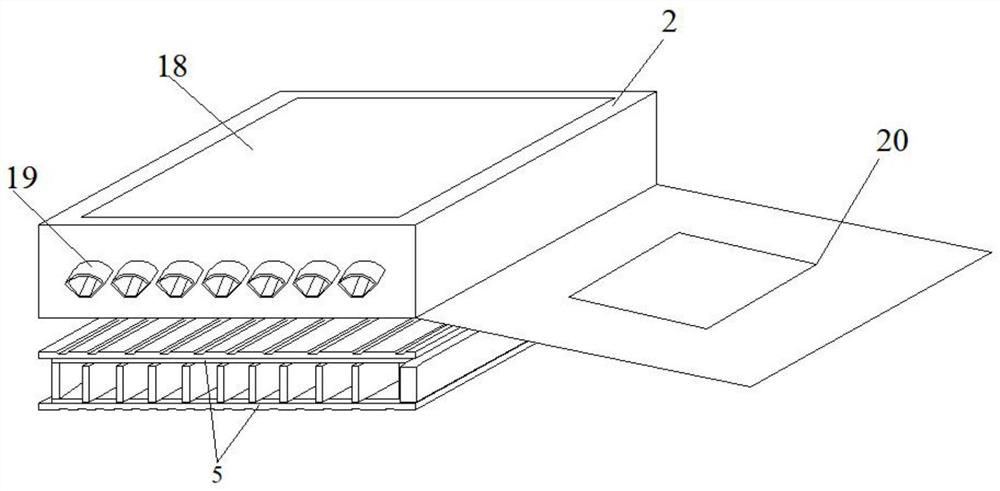

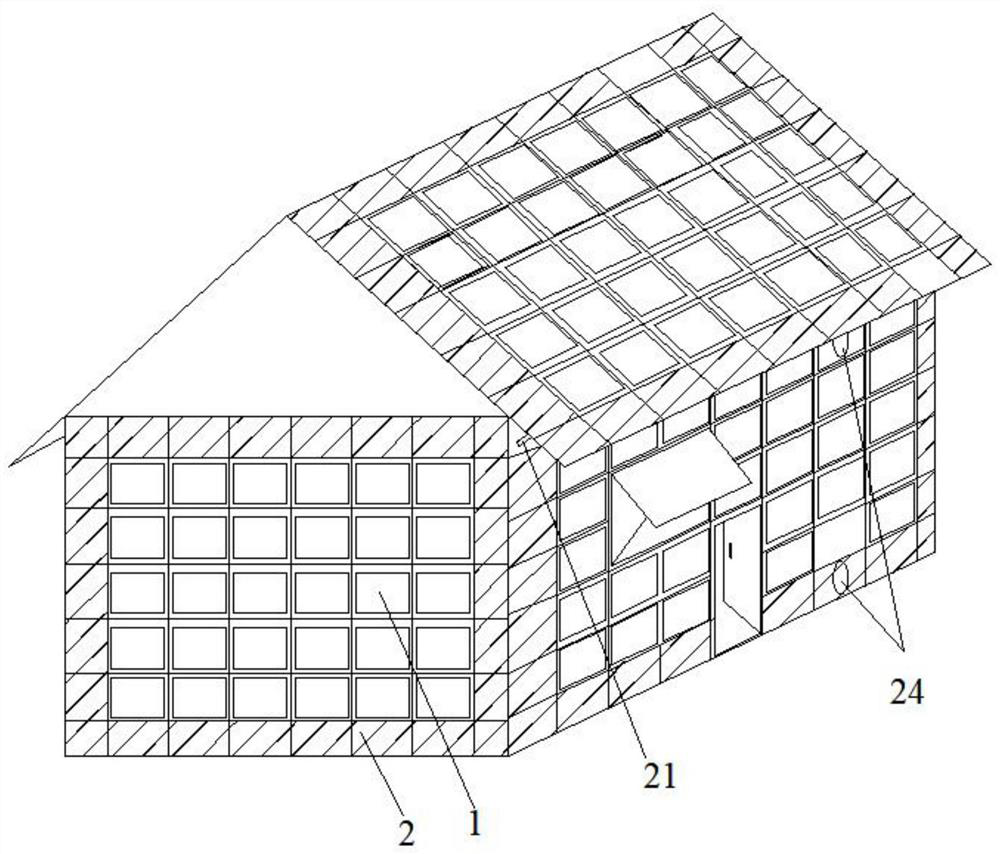

[0027] see Figure 1-9 According to a manufacturing process of a heating module for a solar heating room according to an embodiment of the present invention, several solar heat collecting modules 1 are used to absorb solar heat, and the heat absorbed by the solar heat collecting module 1 is introduced into the room through the solar heat conducting module 2 for heating. , the construction of the heating room is completed in the process of building the heating module, wherein the solar heat collection module 1 includes a solar glass cover plate 3, a solar heat collection cavity module 4 and a wall construction foaming eps module 5, the solar glass cover plate 3 Including solar white cloth tempered glass 6, metal frame 7 and waterproof and temperature-resistant rubber strip 8, solar white cloth tempered glass 6 can also be an endurance board made of plastic material, and the outer edge of the solar white cloth tempered glass 6 is covered by a metal frame 7 Enclosing and covering...

Embodiment approach

[0035] The present invention also provides second kind of embodiment, among the present invention, fan-shaped heat-absorbing pipe 12 and wall construction foaming eps module 5 also can be other shapes, as Figure 5 As shown, the fan-shaped heat-absorbing pipe 12 and the wall construction foaming eps module 5 are connected by screws, and the fan-shaped heat-absorbing pipe 12 is just installed inside the installation groove of the wall construction foaming eps module 5, which is more convenient for disassembly and installation The fan-shaped heat-absorbing tubes 12 are provided with cooling fins inside to increase their heat dissipation efficiency and thereby increase the heating efficiency. The fan-shaped heat-absorbing tubes 12 are mushroom-shaped so that the light-receiving area at the top is large, and at the same time, the gaps between the fan-shaped heat-absorbing tubes 12 are small to facilitate heat preservation. Improve heating effect.

[0036] In addition, in the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com