Treatment equipment for industrial toxic waste gas

A technology for waste gas and equipment, which is applied in the field of treatment equipment for industrial toxic waste gas, can solve problems such as stuck in the burned through inner wall, leakage, and the impact of penetration of transmission pipelines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Figure 1 to Figure 6 Shown:

[0029] The invention provides a treatment equipment for industrial toxic waste gas,

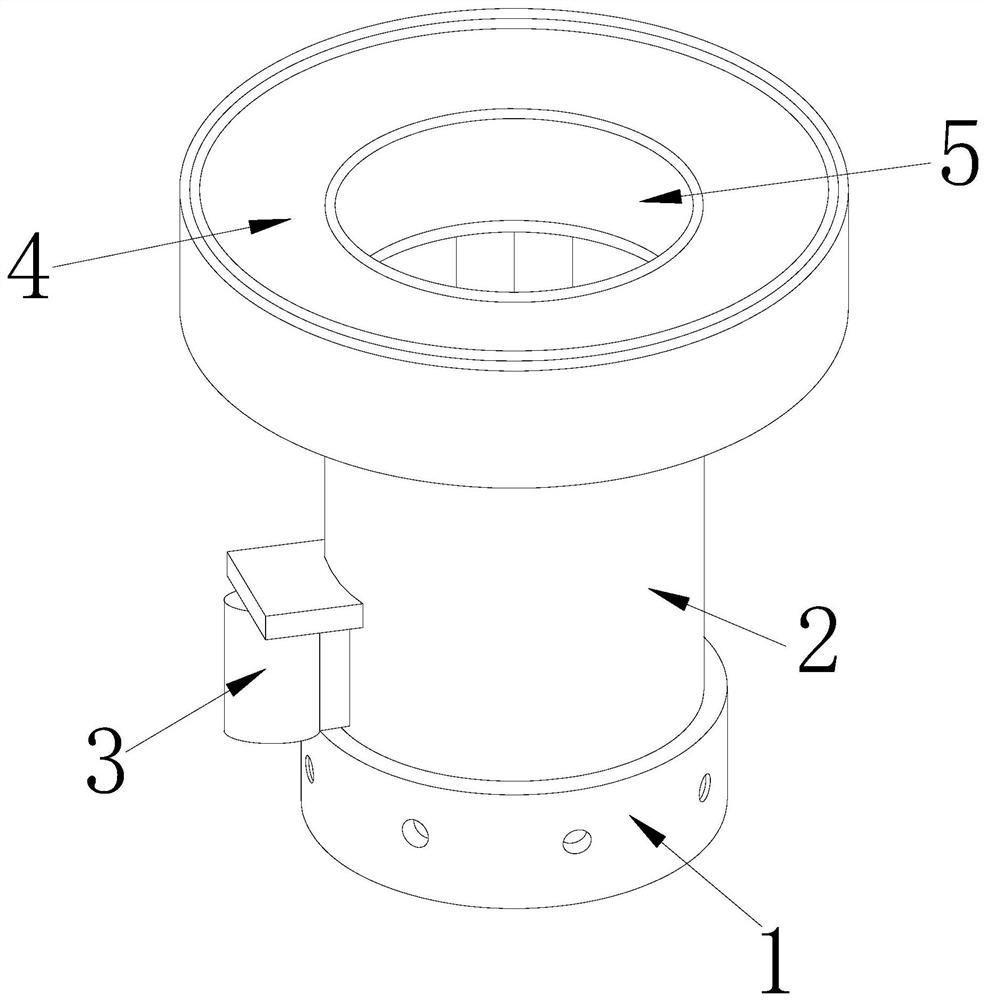

[0030] Its structure includes a base 1, a processing end 2, an electric control box 3, an outlet end 4, and a delivery pipe 5. The upper end of the base 1 is attached to the lower end of the processing end 2, and the electric control box 3 is installed on the processing end 2. The side of the outlet end 4 is fixed above the electric control box 3, and the delivery pipe 5 is embedded in the outlet end 4.

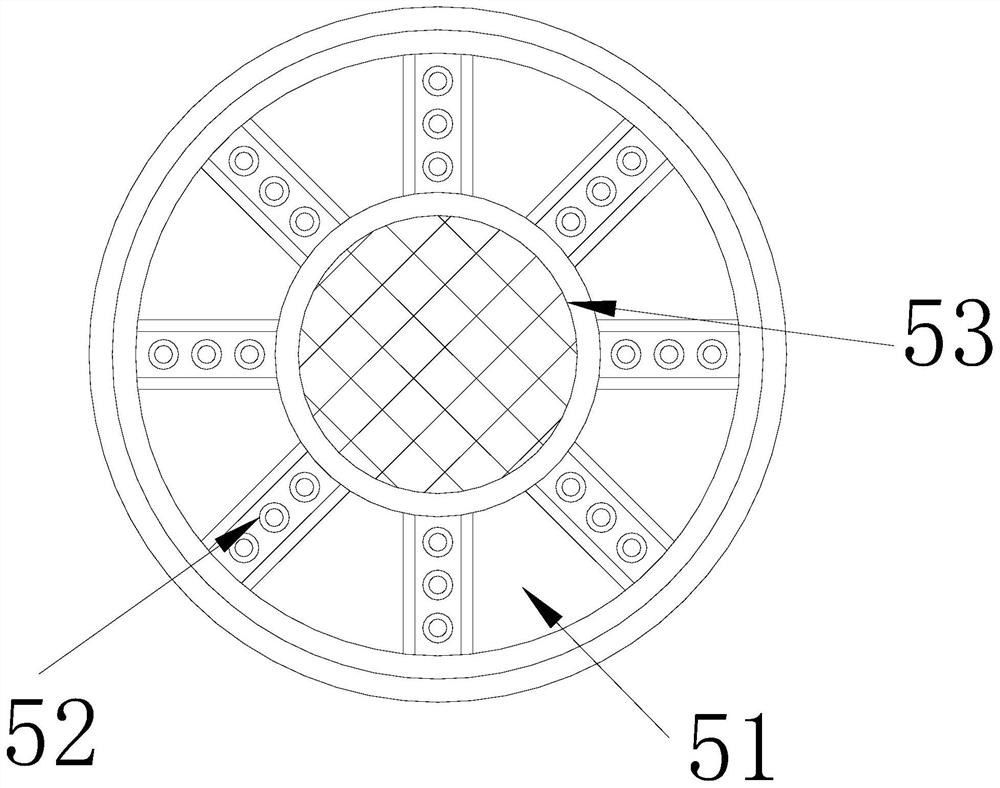

[0031] The delivery pipe 5 is provided with a fixing groove 51, a mounting rod 52, and a through hole 53, the fixing groove 51 is fixedly connected with the mounting rod 52, the through hole 53 is embedded in the mounting rod 52, and the mounting rod 52 There are altogether eight through holes 53 with corresponding gaps therebetween, and the number of the installation rods 52 can enhance the positioning of the through holes 53 .

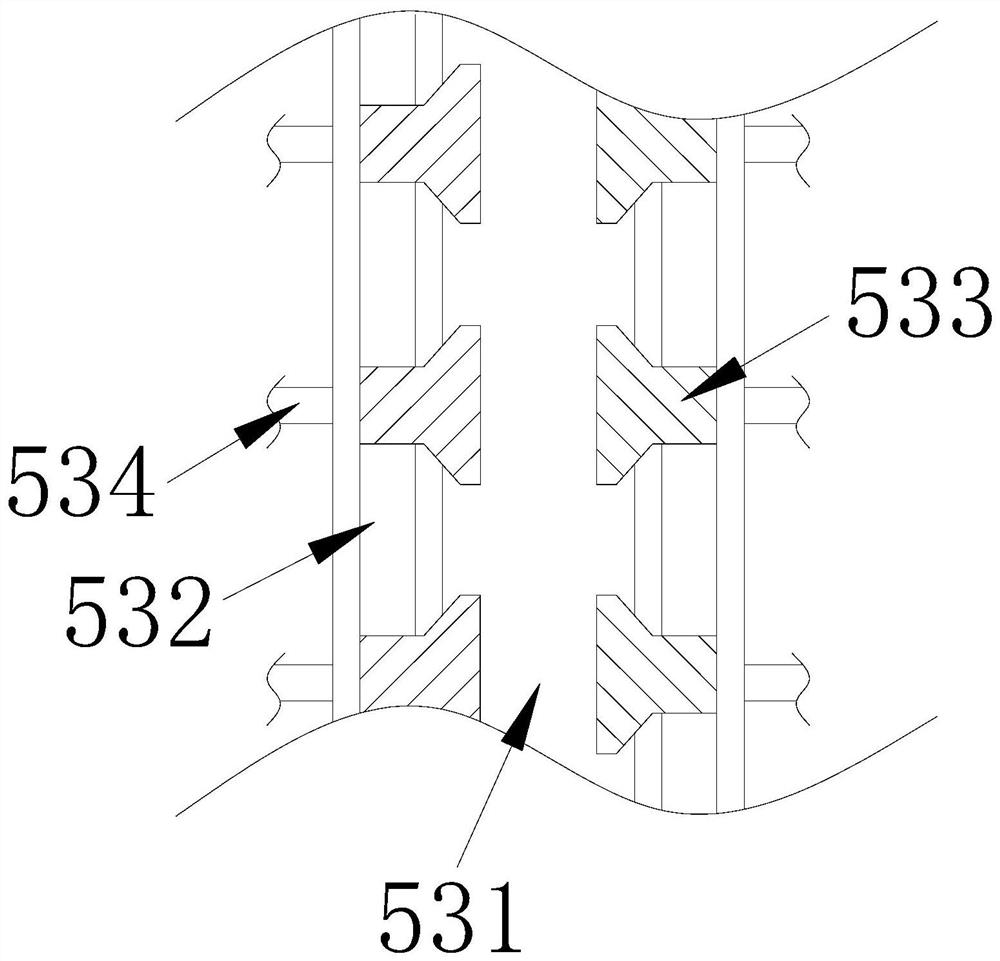

[0032] Wherein, the ...

Embodiment 2

[0039] Figure 7 to Figure 9 Shown:

[0040] The invention provides a treatment equipment for industrial toxic waste gas,

[0041] Its structure includes that the pipe body a4 is provided with an outer layer c1, a threaded shaft c2, and an auxiliary hole c3, the inner side of the outer layer c1 is integrated with the threaded shaft c2, and the auxiliary holes c3 are installed on both sides of the outer layer c1, A total of four auxiliary holes c3 are provided under the outer layer c1 and form a square shape. The auxiliary holes c3 can effectively strengthen the connection effect of the threaded shaft c2 through four directions under the outer layer c1.

[0042] Wherein, the threaded shaft c2 is provided with a pipe c21, an elastic shaft c22, and a support block c23, the pipe c21 communicates with the elastic shaft c22, the support block c23 is movably connected with the elastic shaft c22, and the elastic shaft c22 is a spring Products, the elastic shaft c22 can quickly reset...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com