Real-time database system architecture for intelligent factory

A system architecture and real-time data technology, applied in database management systems, database design/maintenance, manufacturing computing systems, etc., can solve non-standard equipment and system compatibility problems, data collection, processing, storage, analysis lack of system, Security, integrity, no integrated framework and other issues, to achieve the effect of shortening fault repair time, enriching system flexibility and environmental adaptability, and improving versatility and interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0059] The existing traditional factory real-time database system architecture has insufficient scalability, incomplete data collection types, especially low real-time data, collected data that has not been effectively cleaned, extracted, and managed, and cannot provide accurate and comprehensive data services in a timely manner, etc. question. The inability to link data such as personnel, equipment, materials, processes, environment, quality, and logistics in the factory's manufacturing process in real time and completely to support digital businesses such as production management, R&D, and services has become a major obstacle to the digital and intelligent upgrading of factories.

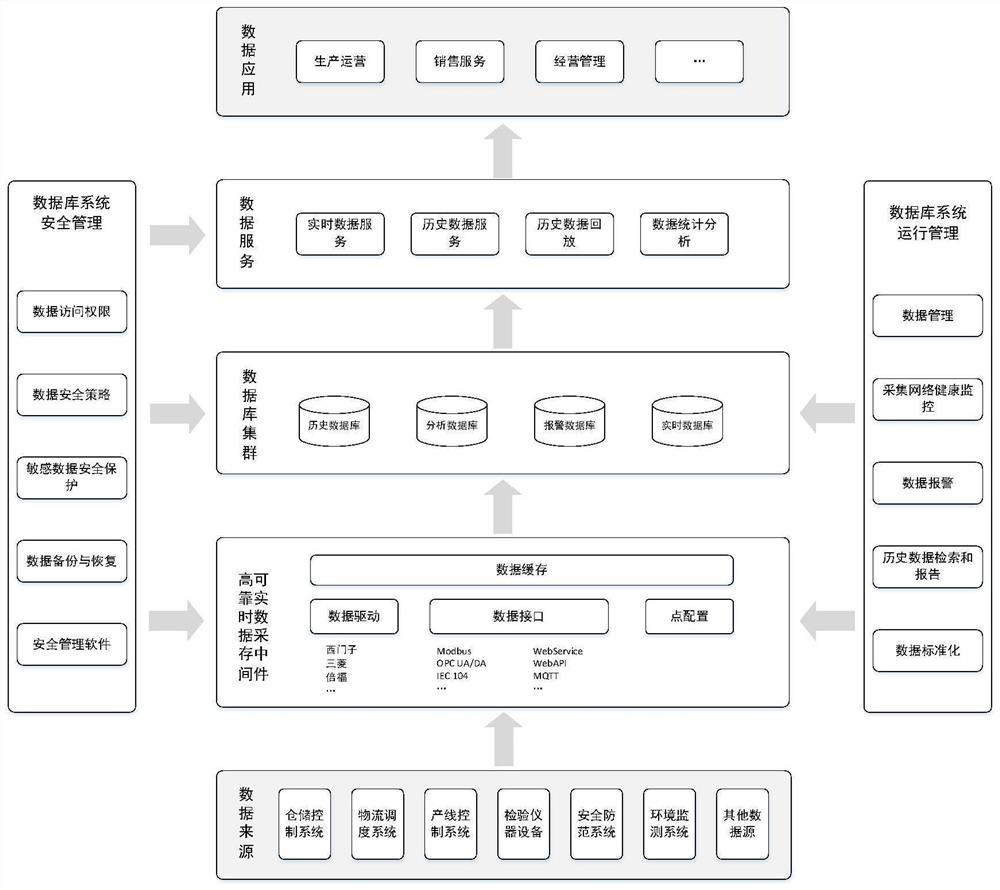

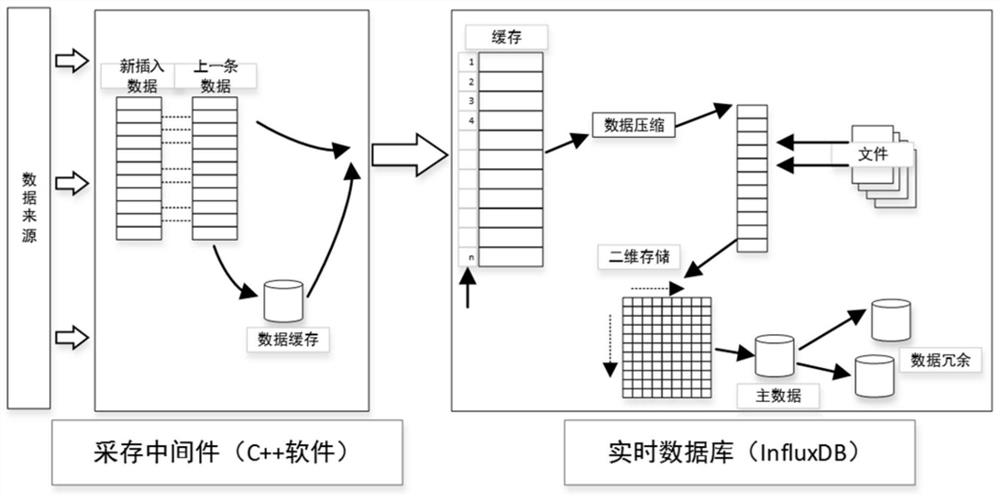

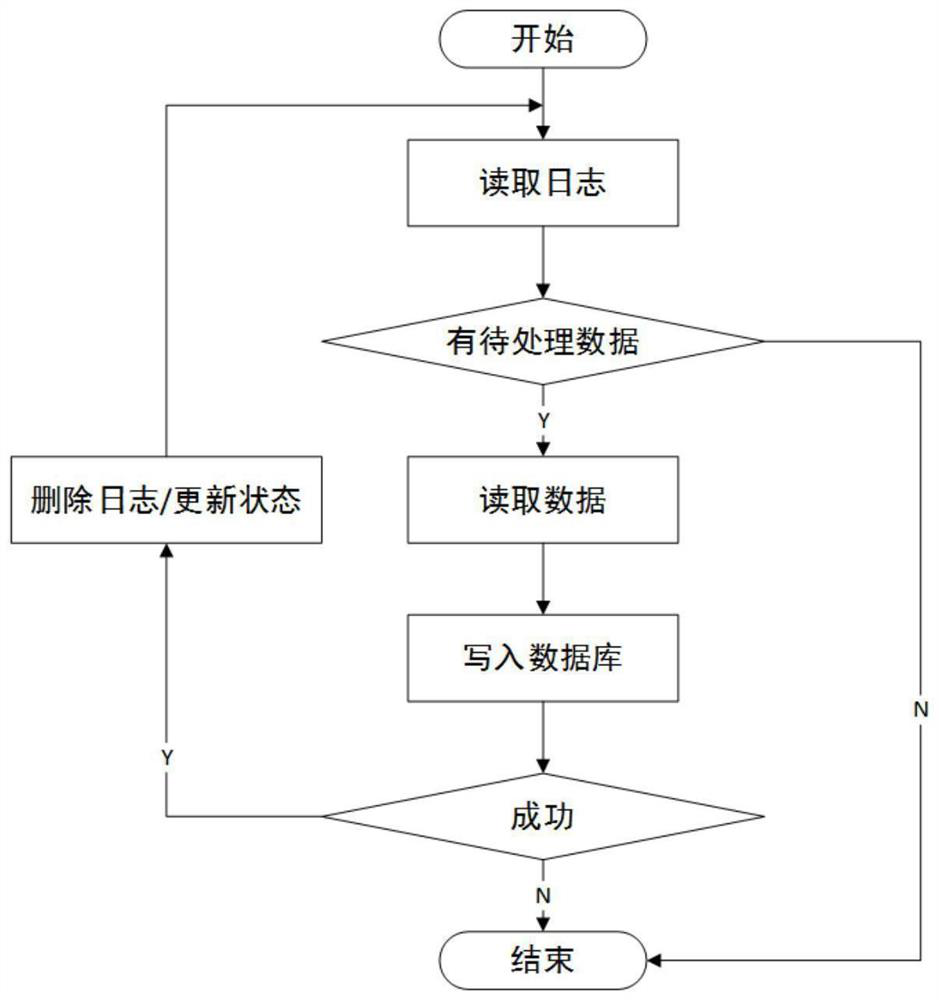

[0060] This embodiment provides a real-time database system architecture for smart factories. This embodiment improves and expands the traditional data acquisition system architecture, and decomposes the system into highly reliable real-time data acquisition middleware, database clusters, and data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com