Method for simulating and calculating heat transfer value of transformer based on three-dimensional model

A technology of three-dimensional model and simulation calculation, which is applied in calculation, computer-aided design, design optimization/simulation, etc., to achieve the effects of improving overload capacity and service life, reducing temperature rise, and optimizing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

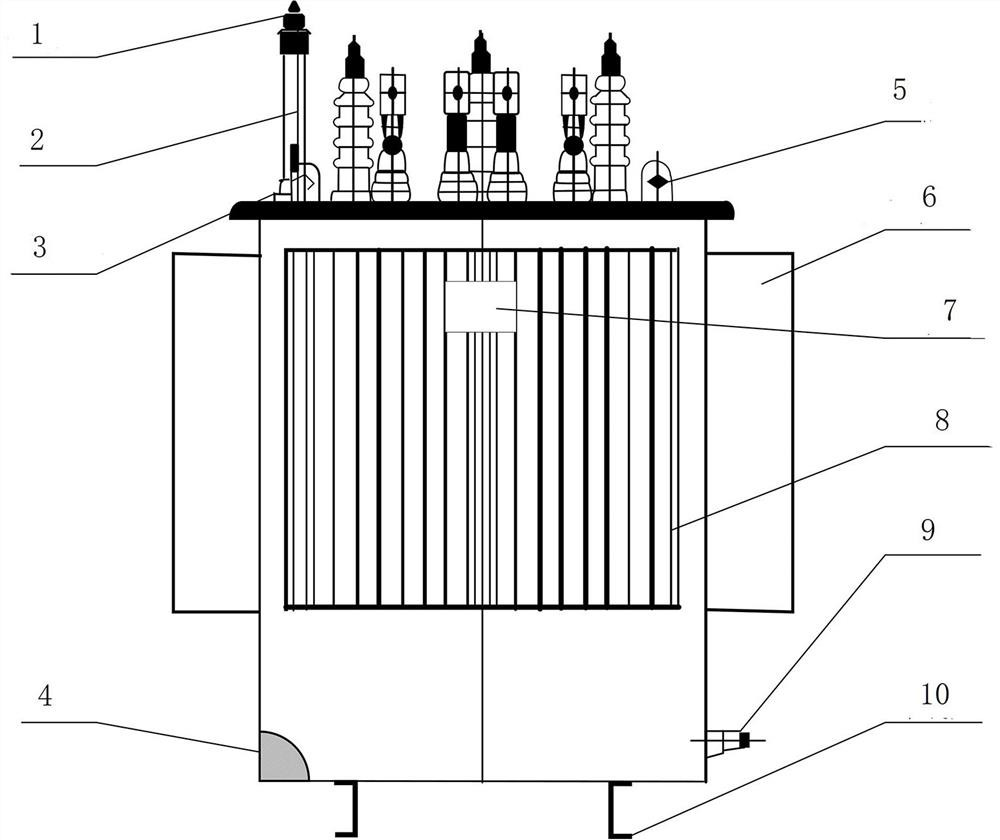

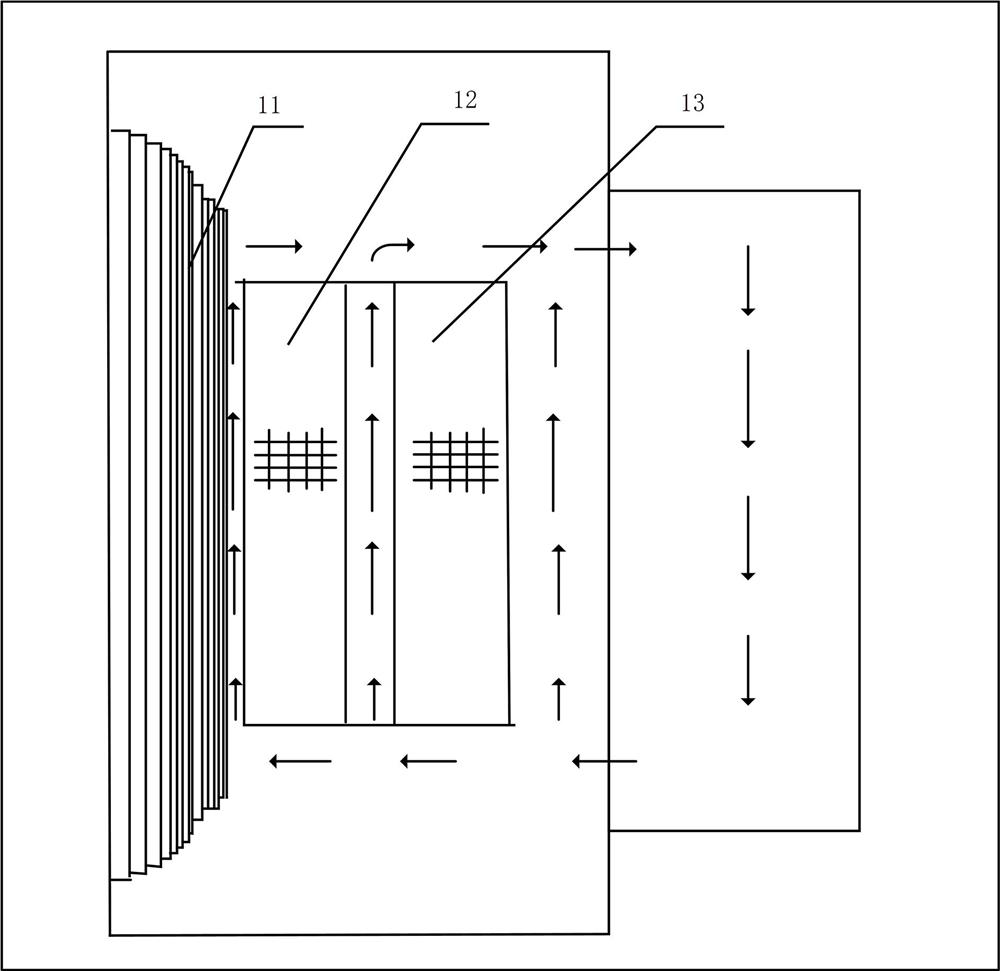

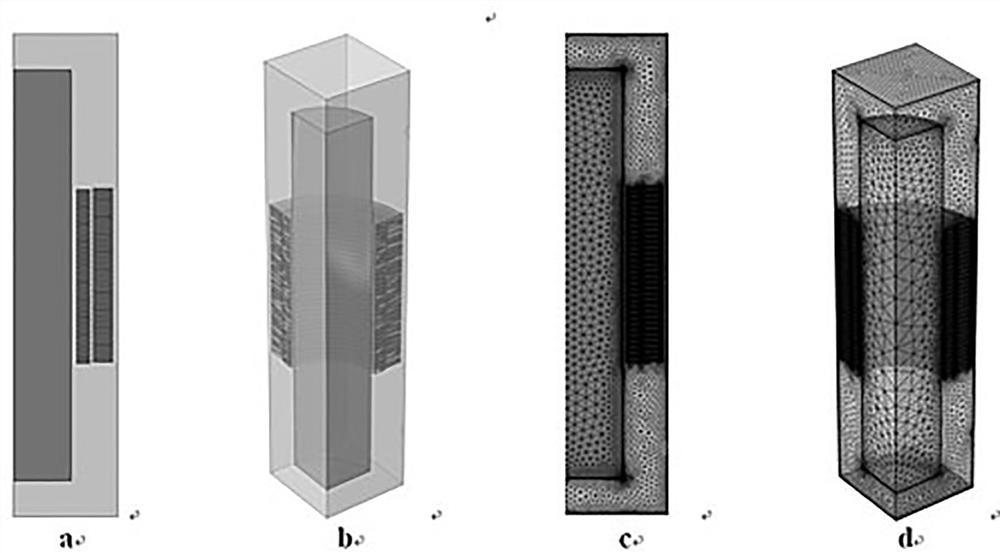

[0061] Such as Figure 1-10 Among them, the transformer design object: determine the material of the iron core 11 in the transformer, the transformer oil, and the winding material.

[0062] In the later stage of the transformer, the iron core 11 is replaced by an amorphous alloy material from silicon steel, the transformer oil is a new type of environmentally friendly vegetable oil, and the winding material is copper.

[0063] The two-dimensional and three-dimensional models of the test transformer and the three-dimensional model of the amorphous alloy vegetable oil distribution transformer were constructed, and the structure was optimized.

[0064] During specific implementation, a 10kV class environment-friendly new plant insulating oil transformer of model S-M-315 / 10-NX2 can be used as a simulation prototype. The high and low voltage windings 12 of the transformer are pie-shaped windings wound by copper wires. In order to improve the overload bearing capacity, the heat-res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com