Electric heating plate type reactor and application thereof

A plate reactor and electric heating plate technology, applied in chemical instruments and methods, sustainable manufacturing/processing, using solid contact hydrogen separation, etc., can solve the problems of wasting fuel heat transfer effect, low production cost, etc., to improve equipment Utilization rate, saving equipment transformation costs, reducing the effect of side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1 propane dehydrogenation reaction

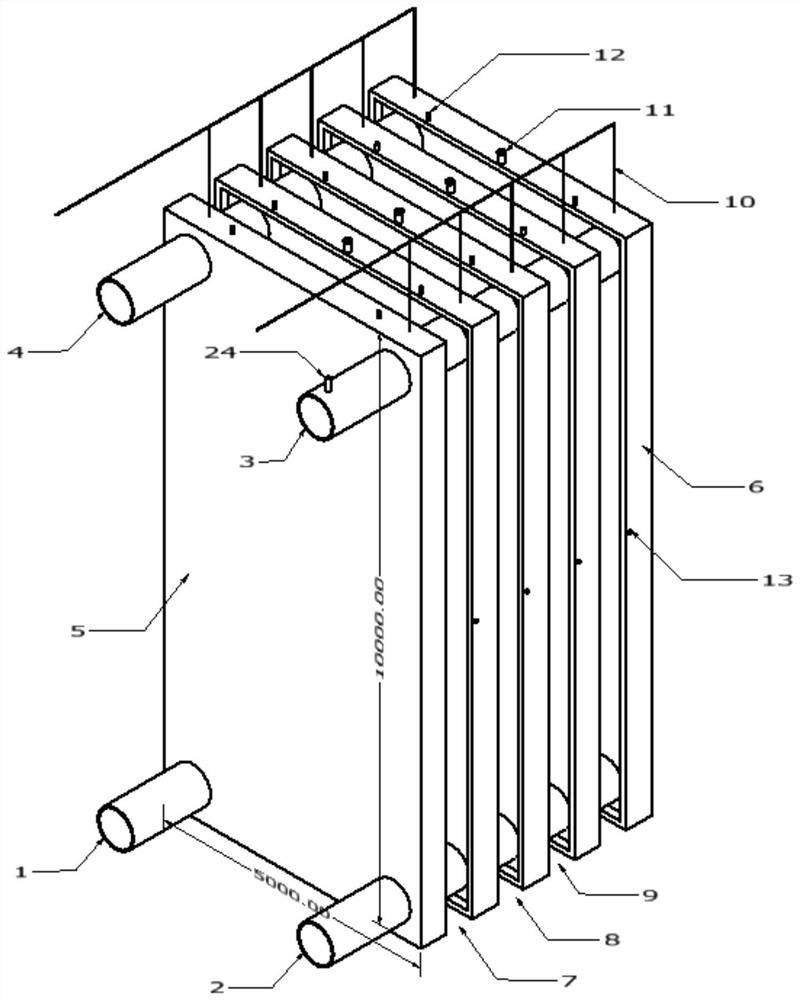

[0056] refer to Figure 1-5 As shown, a propane dehydrogenation reaction process includes a plate reactor, a product gas compression unit, a product gas drying unit, a cold box separation unit, a PSA unit and a membrane separation unit.

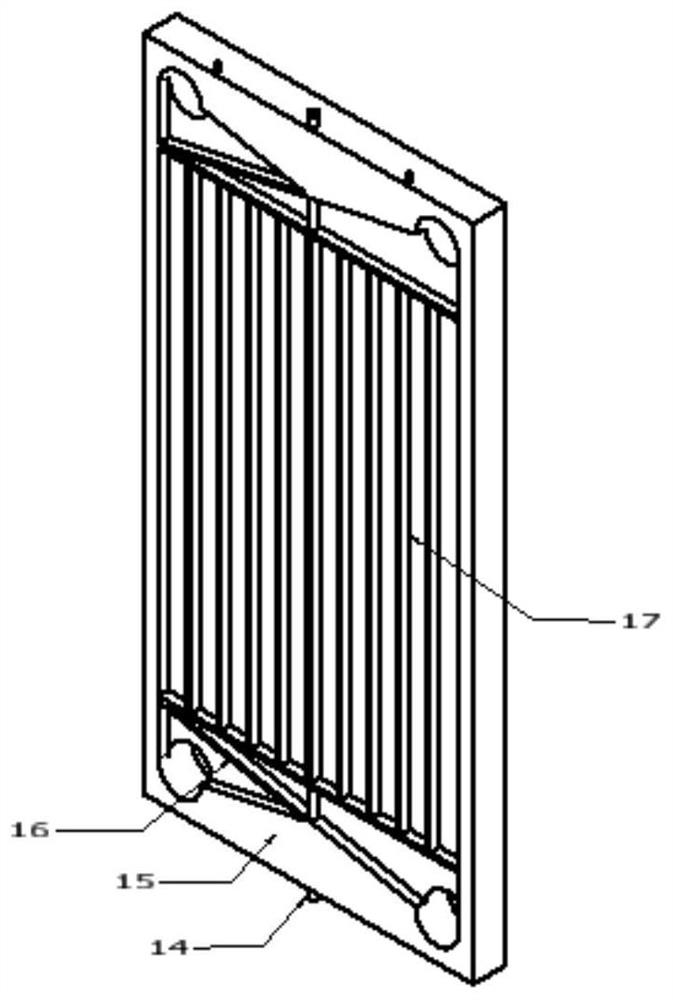

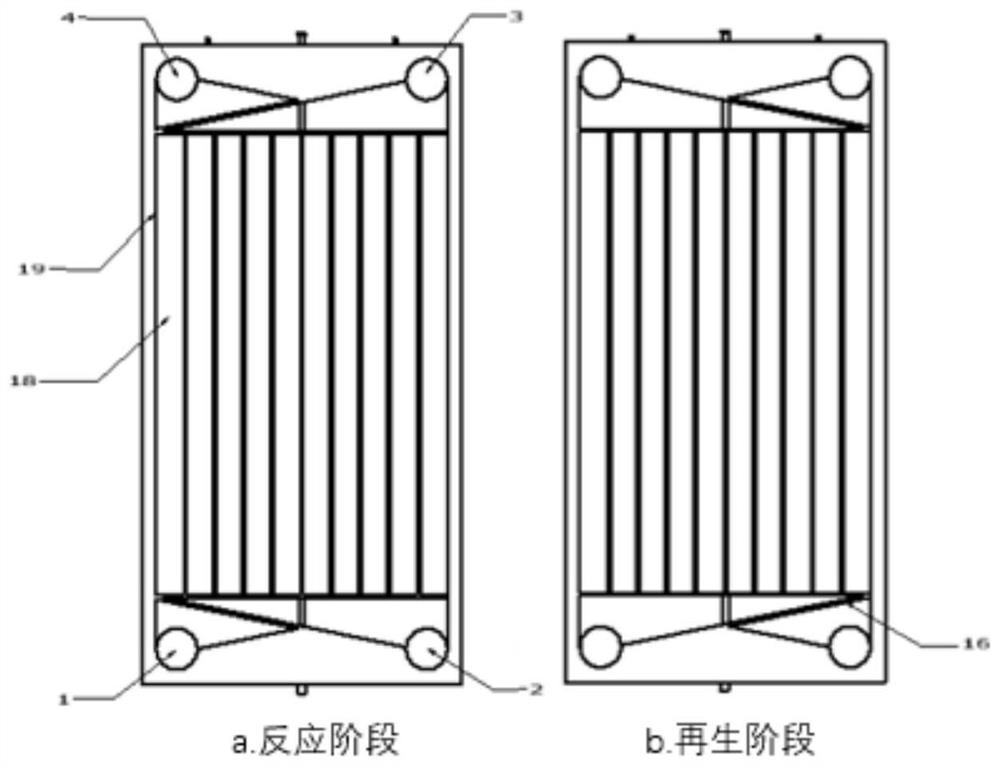

[0057] The plate reactor includes 64 heating plates, and a reaction zone is arranged between two adjacent heating plates, forming 63 reaction zones in total, wherein, the first heating plate is a preheating plate, and no reaction zone is set, and each An electric heating wire is installed on the first heating plate (including the preheating plate), and the heating plate is respectively provided with a reaction gas inlet, a product outlet, a regeneration gas inlet and a regeneration gas outlet. The heating plate 6 is provided with a catalyst loading port 11 and a catalyst discharge port 14, and a catalyst partition 17 is also installed on the heating plate 6, and the reaction zone is divi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com