Powder blowing device at inlet of welding machine

A kind of welding machine technology at the entrance, which is applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of welding quality influence and low welding quality, and achieve the effect of improving quality, increasing scope, and facilitating installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

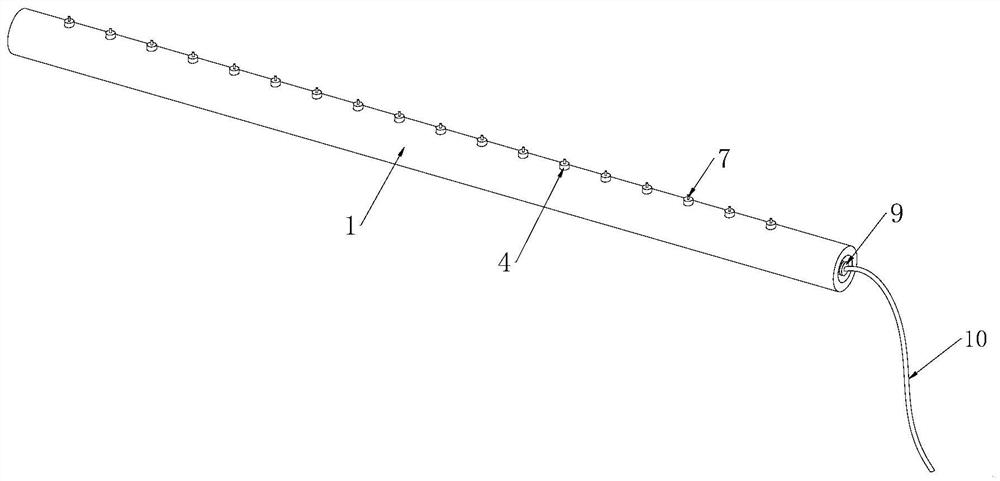

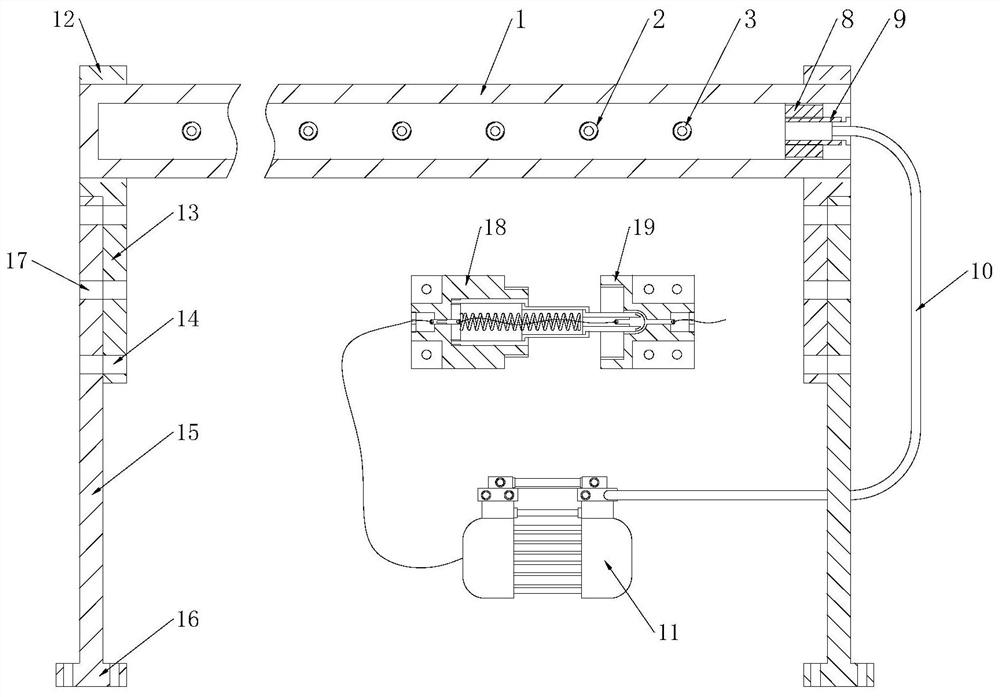

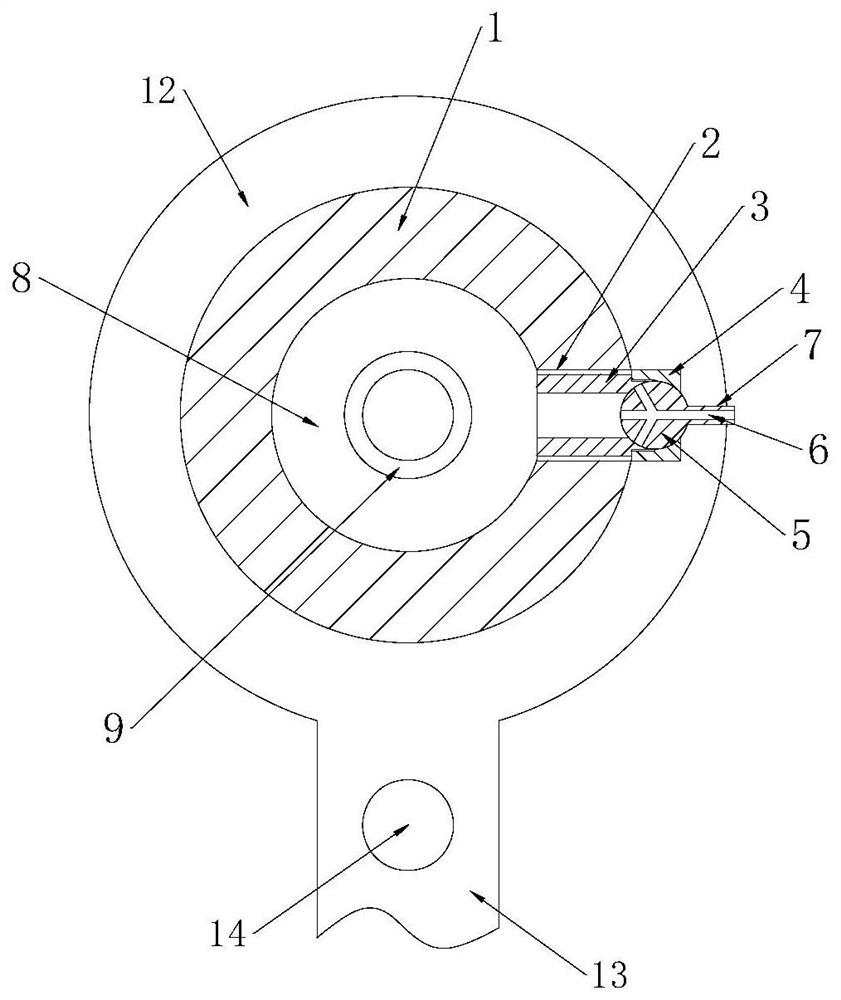

[0028] see Figure 1-5As shown, a powder purging device at the entrance of a welding machine includes a purge beam 1, a blow hole 2 and a purge unit; the purge beam 1 is uniformly provided with blow holes 2; A purging unit is provided; the purging unit includes a base pipe 3, a cover pipe 4, a steel ball 5, an exhaust hole 6 and a guide pipe 7; the air blowing hole 2 is threaded and fixed to a base pipe 3; The base tube 3 is threadedly connected with a cover tube 4; the cover tube 4 and the base tube 3 are rotatably connected with a steel ball 5; the steel ball 5 is fixedly connected with a guide tube 7; the steel ball 5 corresponds to The guide pipe 7 is provided with an exhaust hole 6; one end of the purging beam 1 is internally threaded and fixedly connected with a sealing shaft 8; the sealing shaft 8 is connected and fixedly connected with a pneumatic joint 9; A gas pipe 10 is connected; the other end of the gas pipe 10 is communicated and fixedly connected with the air p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com