Green environment-friendly light aggregate concrete and preparation method thereof

A lightweight aggregate concrete, green and environmental protection technology, applied in the field of building materials, can solve the problems of high water absorption, large porosity of ceramsite, poor durability and strength of concrete, and achieve the effect of improving durability and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

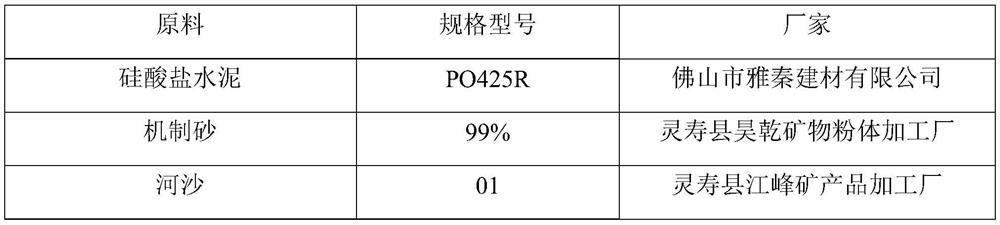

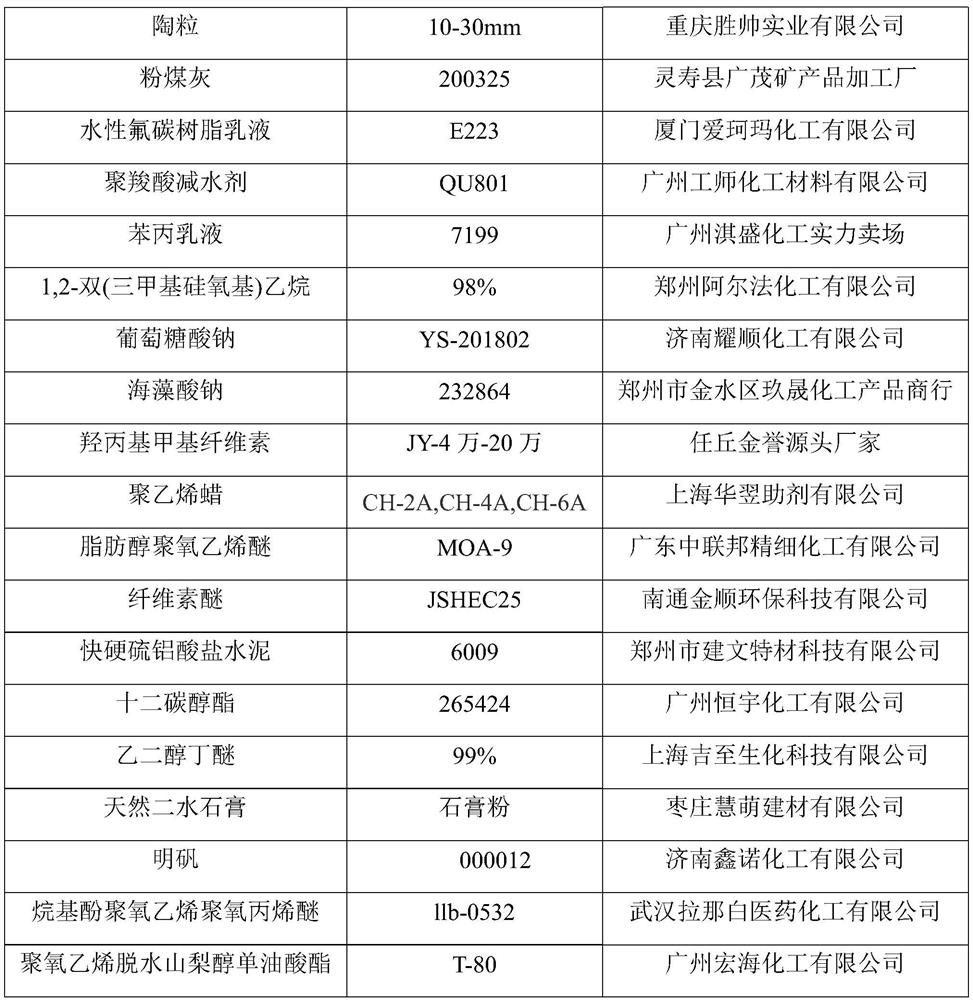

Method used

Image

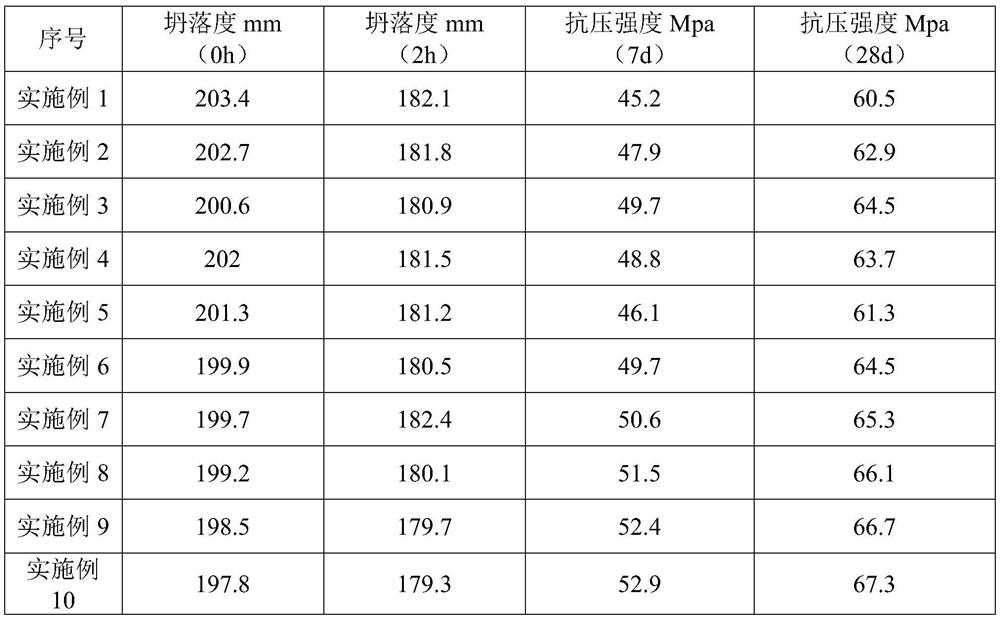

Examples

Embodiment 1

[0064] The green environment-friendly lightweight aggregate concrete of this embodiment is composed of the following raw materials: Portland cement 220kg, water 200kg, machine-made sand 180kg, river sand 130kg, ceramsite 120kg, fly ash 50kg, admixture 5kg, viscose Binder 5kg, wherein the admixture is composed of water-based fluorocarbon resin emulsion and polycarboxylate water reducer in a mass ratio of 6:5, and the binder is composed of styrene-acrylic emulsion, 1,2-bis(trimethylsiloxy)ethyl Alkanes are composed at a mass ratio of 1:1.

[0065] The preparation method of the green environment-friendly lightweight aggregate concrete of the present embodiment comprises the following steps:

[0066] (1) Mix Portland cement, machine-made sand, river sand, ceramsite, and fly ash evenly to obtain the mixture;

[0067] (2) Add water into the mixture, mix and stir, add admixture and binder, mix and stir evenly.

Embodiment 2

[0069] The green environment-friendly lightweight aggregate concrete of this embodiment is composed of the following raw materials: Portland cement 250kg, water 220kg, machine-made sand 200kg, river sand 150kg, ceramsite 130kg, fly ash 70kg, admixture 6kg, viscose 8kg of binding agent, 2kg of film-forming aid, 3kg of expansion agent, and 2kg of surfactant, wherein the admixture is composed of water-based fluorocarbon resin emulsion and polycarboxylate water reducer in a mass ratio of 6:5, and the binder is composed of styrene-acrylic emulsion , 1,2-bis(trimethylsiloxy)ethane in a mass ratio of 1:1, the film-forming aid is composed of dodecyl alcohol ester and ethylene glycol butyl ether in a mass ratio of 2:3, and the expansion agent It is composed of calcined magnesia, natural dihydrate gypsum, and alum in a mass ratio of 2:3:4, and the surfactant is composed of alkylphenol polyoxyethylene polyoxypropylene ether and polyoxyethylene sorbitan monooleate in a mass ratio of 2 :3 ...

Embodiment 3-5

[0074] Embodiment 3-5 respectively provides the green environment-friendly lightweight aggregate concrete with different proportions of each component of the raw material, the proportion of raw material components of the green environment-friendly lightweight aggregate concrete corresponding to each embodiment is shown in Table 2, and the proportion of raw materials is in unit for kg.

[0075] Table 2 Example 2-5 The distribution ratio of each component of the green and environment-friendly lightweight aggregate concrete

[0076] raw material Example 2 Example 3 Example 4 Example 5 Portland cement 250 260 270 280 water 220 230 240 250 Machine-made sand 200 230 240 250 river sand 150 160 170 180 Ceramsite 130 135 140 150 fly ash 70 80 90 100 Admixture 6 7 8 10 binder 8 8 9 10 Coalescent 2 2 2 1 expansion agent 3 3 3 2 Surfactant 2 2 2 1

[0077] The difference...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com