Method for culturing cells by using circular-track shaking type bioreactor

A bioreactor and cell culture technology, which is applied in the field of culturing cells using an orbital shaking bioreactor, can solve problems such as differences in working principles and unsuitable culture conditions, and achieve improved expression, high protein expression and specific production. speed, the effect of prolonging the incubation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

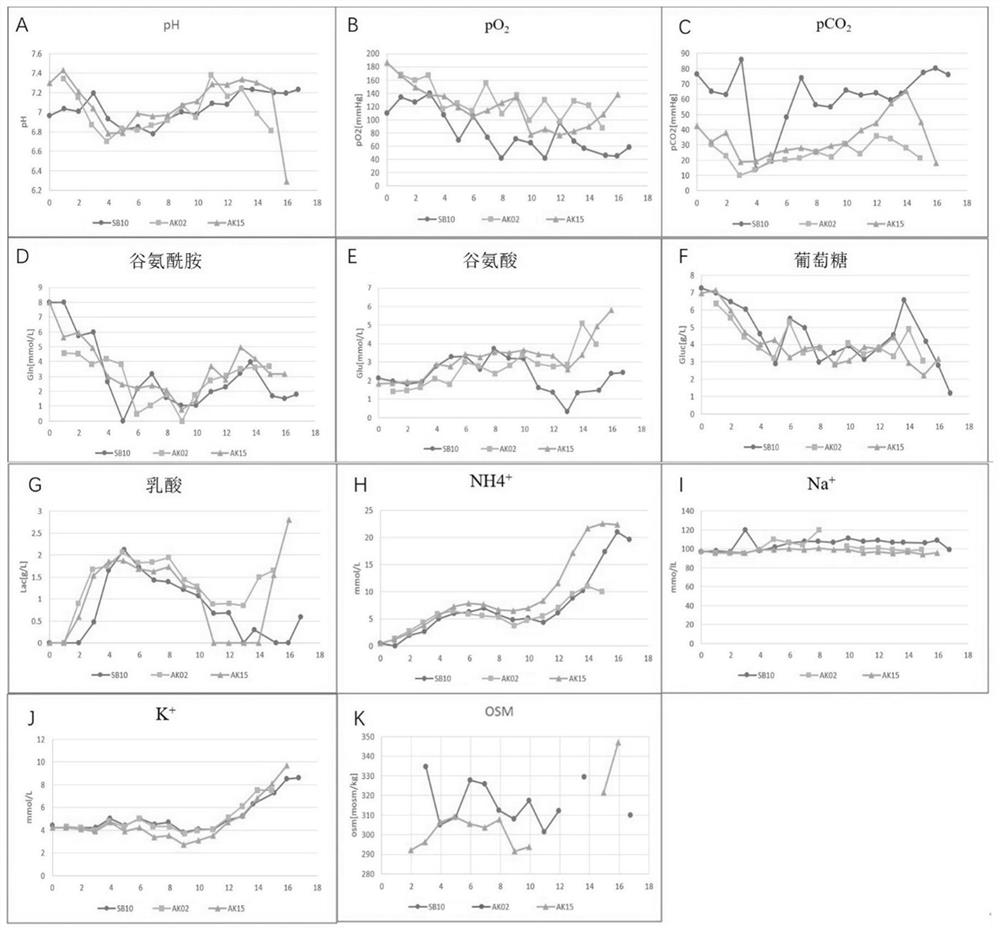

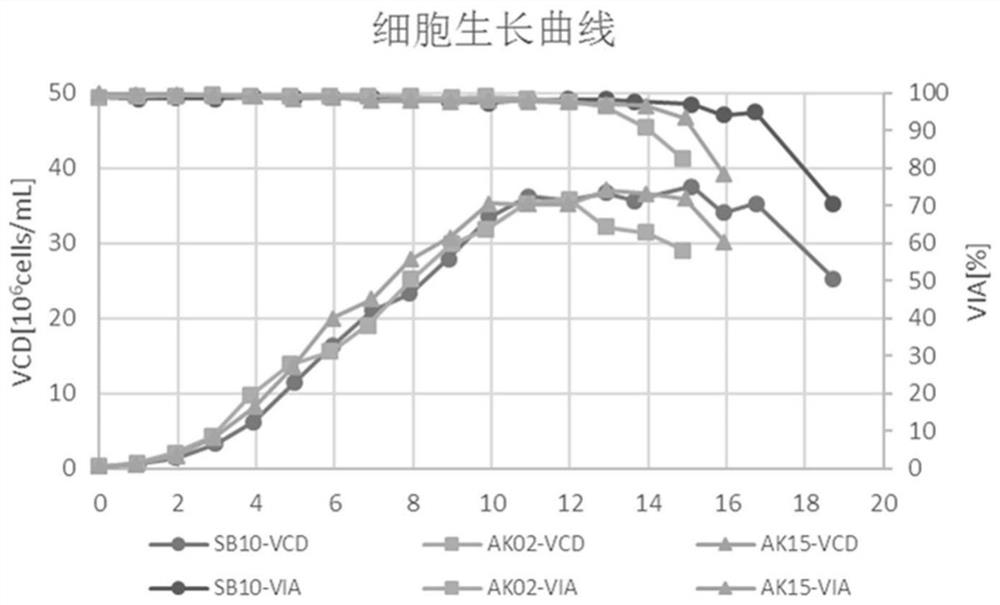

[0055] A method for cultivating cells using a ring-orbit shaking bioreactor, inoculating cell strains in a medium at a certain density for cell cultivation. The conditions for culturing cells in Example 1, Comparative Example 1, and Comparative Example 2 are shown in Table 1.

[0056] The culture condition of table 1 comparative example and embodiment

[0057]

[0058]

[0059] Note: N / A means not applicable.

[0060] During the cultivation period, the contents of glucose and glutamine in the medium are monitored in real time, and if the contents are lower than the minimum value of the defined range, glucose and glutamine need to be added to the medium.

[0061] pH control strategy: monitor the pH of the medium in real time, if the pH is lower than the above pH range, add 1M NaHCO 3 Raise the pH, if the pH is below the above pH range, pass CO 2 Lower the pH.

[0062] DO control strategy: monitor the dissolved oxygen in the medium in real time, and control the dissolved...

Embodiment 2

[0072] Example 2 and Example 1 have the same culture conditions except that there is a difference in the pH value of the medium. The pH of the culture medium in Example 2 was 7.0.

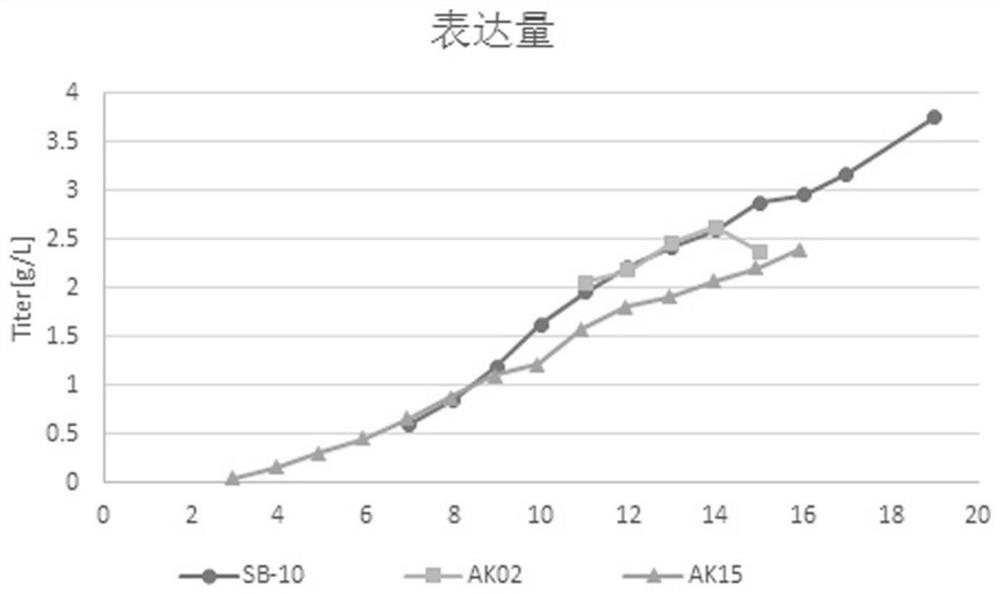

[0073] During the process of culturing cells, a cell counter (Beckman Company) was used to detect cell density and viability, and a biochemical analyzer (NOVA, USA) was used to detect nutrients. After the cell culture was completed, the supernatant was collected after centrifugation. The supernatant was collected by high-performance liquid chromatography to collect anti-human CD20 monoclonal antibody (anti-CD20 Mab), and its expression yield was detected.

[0074] The results show that the fixed pH setting value cell growth state is close to that in Example 1, pCO 2 The proportion increased, but the expression level did not decrease significantly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com