Track gauge adjustable ballastless turnout base plate fastening system

A backing plate and turnout technology, which is applied in the field of the backing plate fastening system of adjustable gauge ballastless turnout, can solve the problems of increasing the maintenance cost of the turnout, the composite positioning sleeve has no anti-rotation function, and the hidden danger of loose bolts of the turnout sleeper, etc. Daily maintenance workload, reducing the risk of shearing, and avoiding the effect of rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

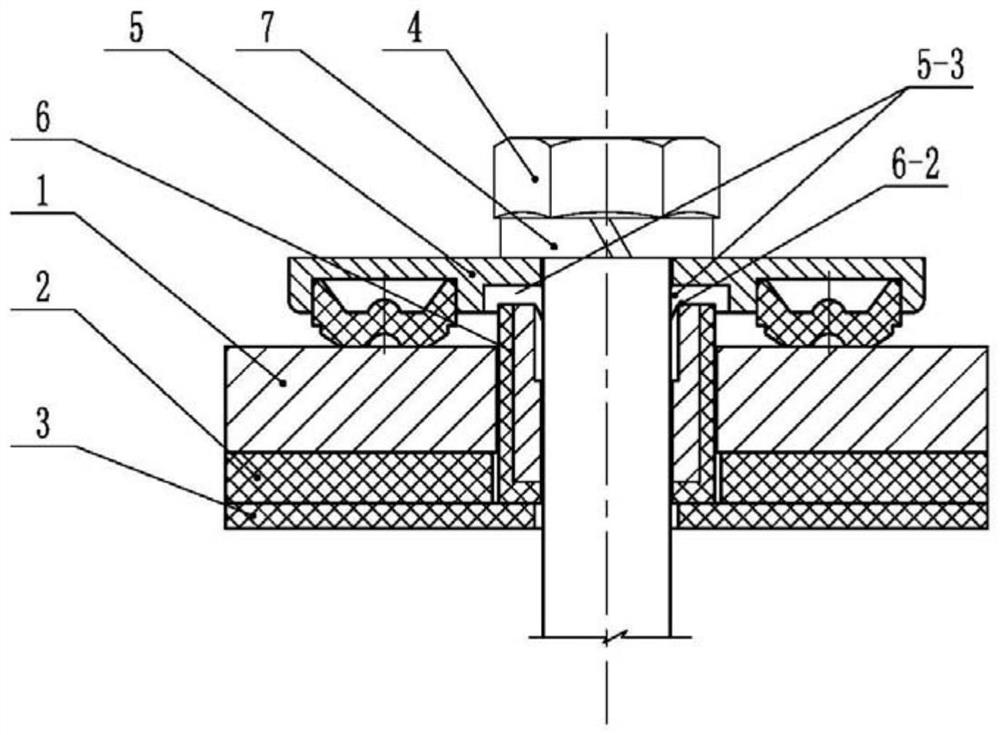

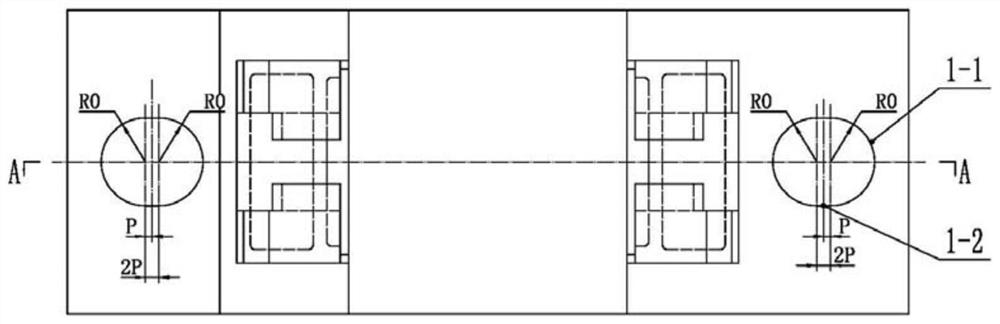

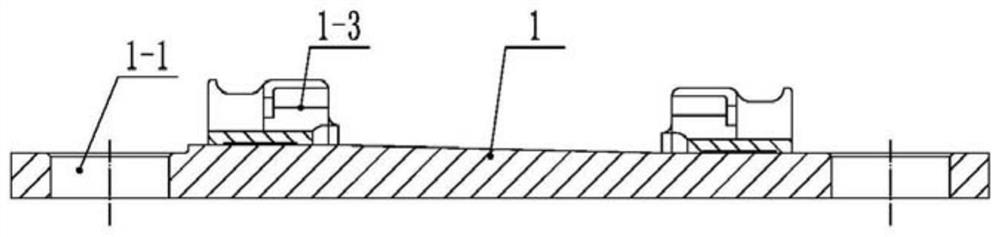

[0030] Embodiment 1: A fastening system for ballastless turnout backing plate with adjustable gauge, including iron backing plate 1, elastic backing plate 2, height-adjusting backing plate 3 and turnout bolts 4, and elastic backing plate 2 is set on the iron backing Below the plate 1, the height-adjusting backing plate 3 is arranged below the elastic backing plate 2; the upper end surface of the iron backing plate 1 has two iron seats 1-3, and the gauge block is passed between the two iron seats 1-3. 8. The rail 9 is installed on the spring bar 10; the elastic backing plate 2 is consistent with or slightly larger than the iron backing plate 1 on the upper part, and the thickness is 5mm to 20mm. It is the main bearer of the elastic effect of the fastener system and provides the ballastless track. Elasticity, the material is EPDM foam rubber or polyurethane; the height adjustment backing plate 3 is made of high-density polyethylene or rubber and plastic, which is consistent with ...

Embodiment 2

[0039] Embodiment 2: On the basis of Embodiment 1, the structure of the eccentric sleeve 6 is further optimized, that is, the eccentric sleeve 6 is composed of a non-eccentric steel sleeve 6-3 and an eccentric buffer coated on the outer wall of the non-eccentric steel sleeve 6-3 The outer diameter of the eccentric buffer sleeve 6-4 is composed of two opposite semicircles with the same radius R connected by a straight section 6-1, and the center of the eccentric buffer sleeve 6-4 faces The eccentric value of left or right is e, so that the eccentric value of the center of the circular inner hole of the non-eccentric steel sleeve 6-3 and the center of the first oblong hole 1-1 is e.

[0040] The circular inner hole of the non-eccentric steel sleeve 6-1 has a stepped structure, and the upper inner diameter is larger than the lower inner diameter. The height of the lateral force action point of the turnout bolt 4 can be reduced, and the risk of the turnout bolt 4 being sheared can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stiffness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com