Anti-seismic anti-cracking prefabricated concrete pile and machining method thereof

A prefabricated concrete and concrete technology, which is applied in the field of concrete piles, can solve the problems of poor anti-seismic and anti-cracking effect of prefabricated concrete piles and the rapid spread of cracks, and achieve the effect of preventing the rapid spread of cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

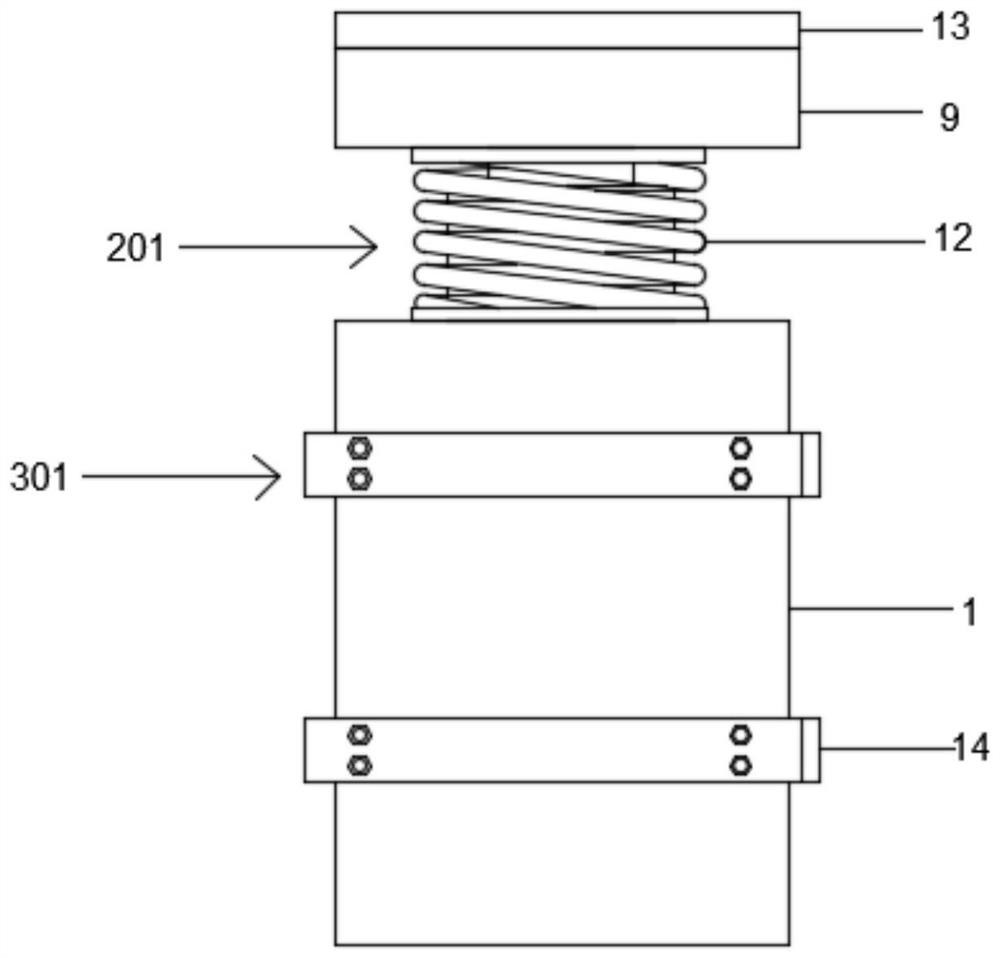

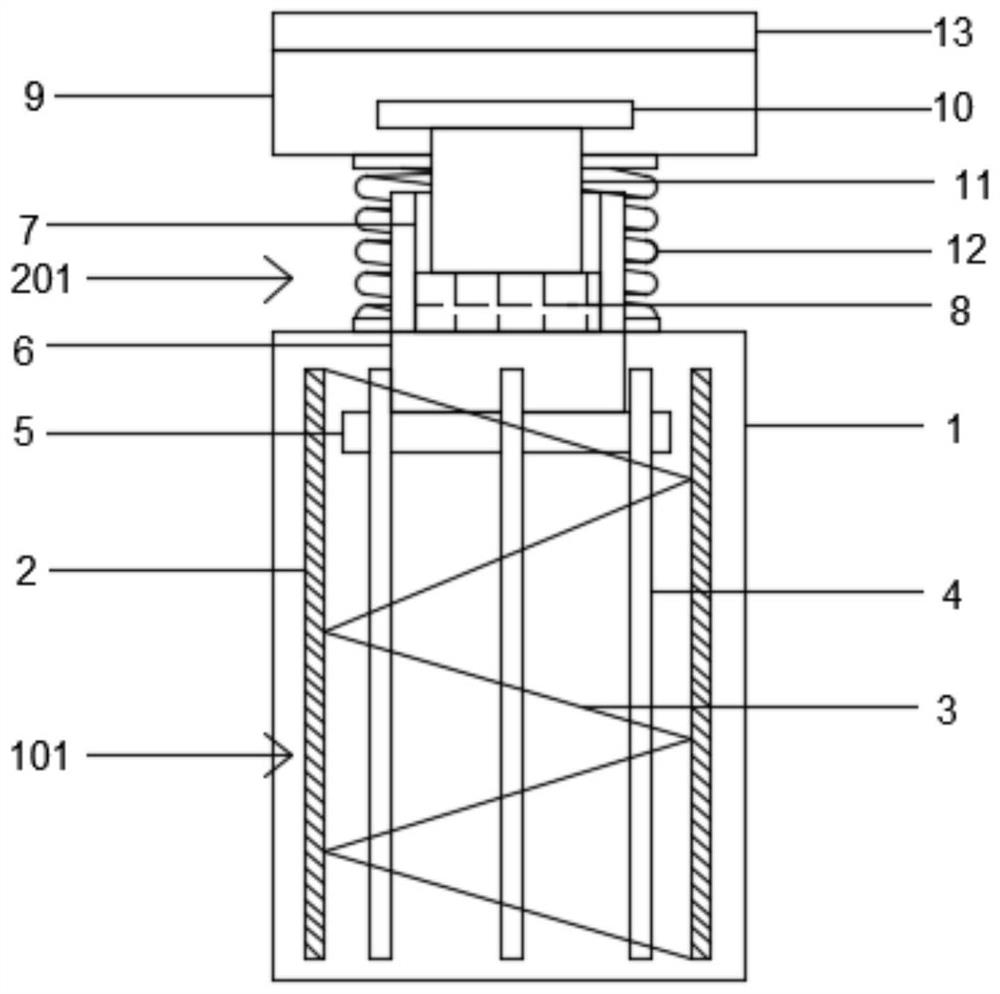

[0032] Refer to the attachment Figure 1-3 A precast concrete pile and crack seismic processing method of the present invention provides, including a concrete;

[0033] Further, equipped with a concrete reinforcement cage member 101, one side of the concrete member 201 is provided with the damper, the damper member 201, is provided with an external concrete crack member 301, the upper shock absorbing member 201 is provided with the damper mass 9 , fixed to the upper end of the damper mass 9 is attached to the mounting block 13, specifically, the damper member 201 plays the role of the damping damper mass 9, functions as the mounting block 13 mounted together with other objects.

[0034] Further, the cage member 101 includes a reinforcement stirrup 3, 3 stirrup shape of an annular shape, the side wall 3 is fixed stirrups are mounted vertically prestressed steel reinforcement 2 and 3 common, ordinary prestressed steel reinforcement 2 and 3 form cylindrical shape, prestressing steel a...

Embodiment 2

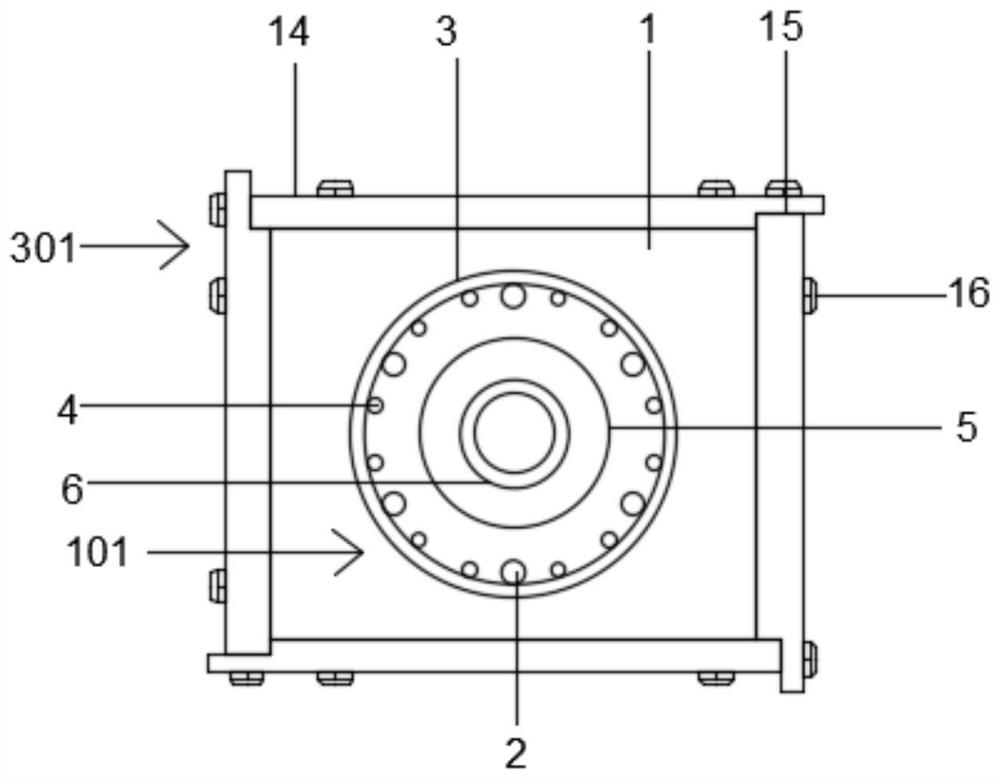

[0039] Refer to the attachment Figure 4-6 Precast concrete piles and crack An anti-vibration processing method provided by the invention, comprising a crack control member 301;

[0040]Further, the anti-crack member 301 is a mounting groove 17 and a fixing plate 2 18, and the mounting groove 17 is provided with two groups. The mounting groove 17 is opened on the outer wall of the concrete 1, and the fixing plate 2 18 is provided with two groups, each set of fixed plates 2 18. It is provided with four pieces, and the fixing plate 2 18 is fixedly coupled by a bolt 16, and the fixing plate 2 18 is mounted within the mounting groove 17 by a bolt 16, specifically, securing the fixed plate 2 18 first tail, and then fixes The plate 2 18 is fixedly mounted in the mounting groove 17 on the outer wall of the concrete 1, which can prevent the cracks from cracking rapidly when the concrete 1 cracks.

[0041] The use process of the present invention is as follows: Comparative Example 1, the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com