Main steam pressure variable rate control method for assisting RB process steam drum water level control

A technology of drum water level and main steam pressure, applied in control systems, components of steam boilers, steam boilers, etc., can solve problems such as recovery, failure to consider the mechanism relationship of related operating parameters, and failure to consider the influence of steam pressure operating parameters. , to ensure the operation status, ensure operation safety, and reduce fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

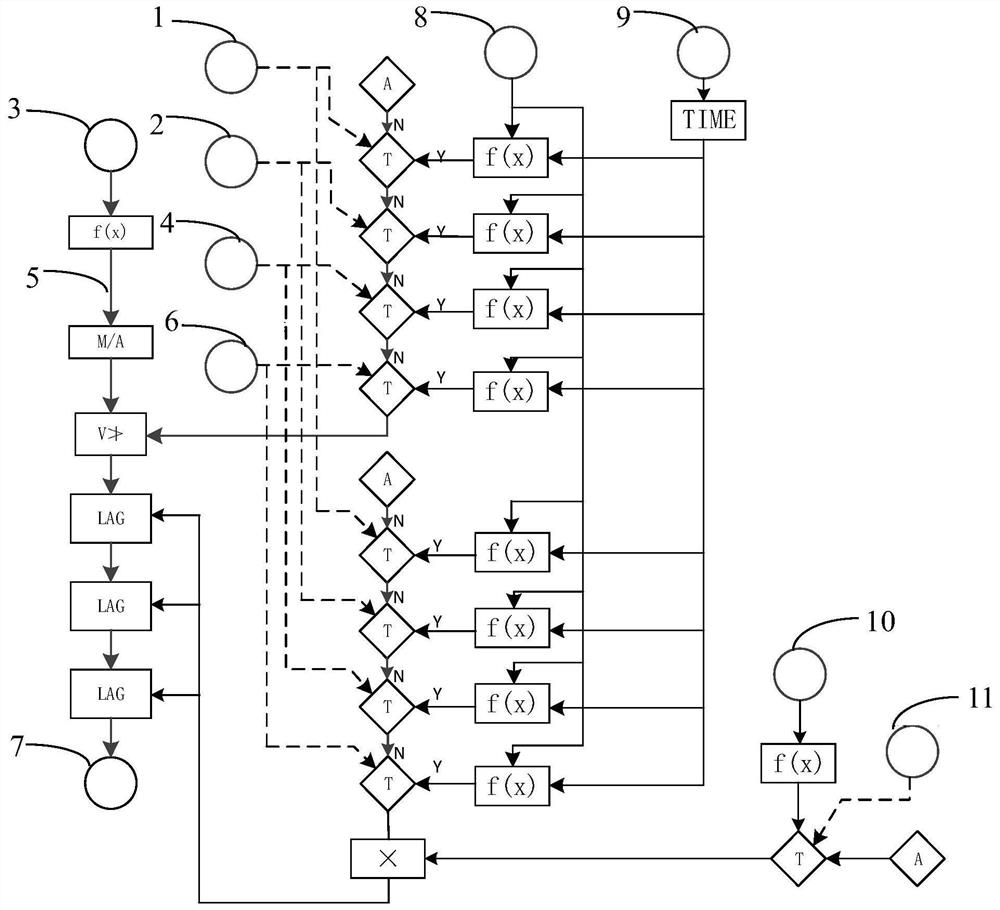

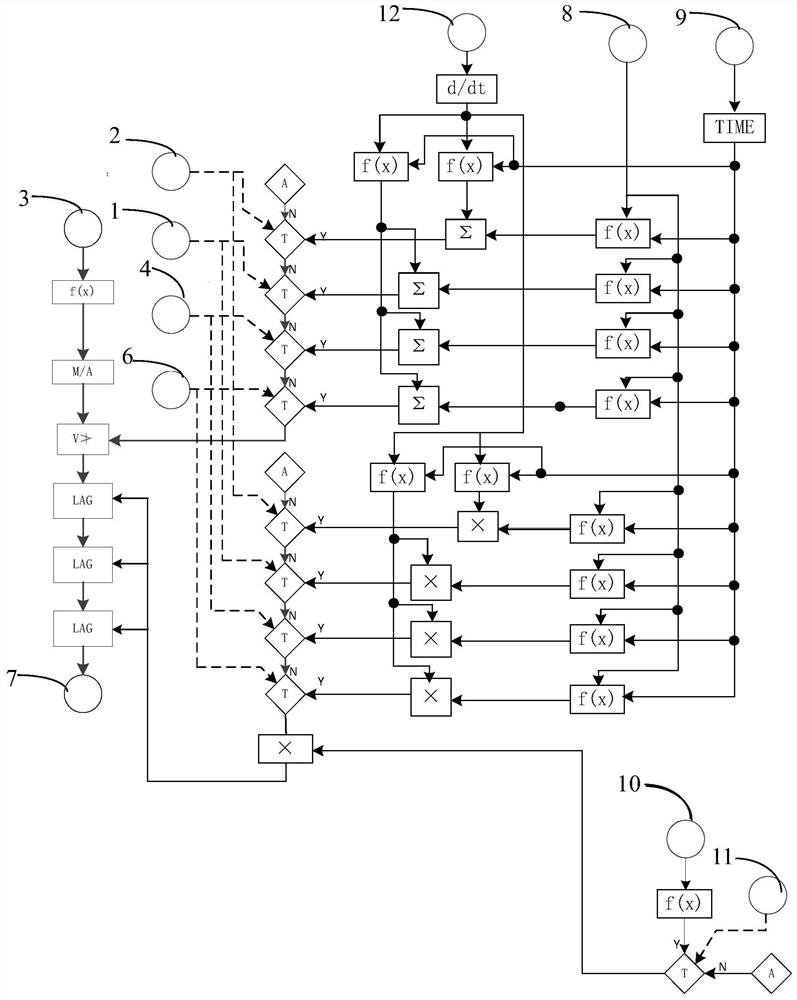

[0049] Embodiment 1 of the present application is based on the method of controlling the variable rate of the main steam pressure in the RB process, starting from the mechanism relationship between the dynamic characteristics of the drum water level and the change trend of the main steam pressure in the RB process, and provides a method such as figure 2 The main steam pressure variable rate control method for drum water level control in the auxiliary RB process shown is divided into feed water pump RB working conditions and non-feed water pump RB working conditions:

[0050] Step 1. Carry out differential calculation on the steam drum water level value to obtain the change rate of the steam drum water level;

[0051] Step 2. Due to the different effects of boiler combustion and feed water on the water level of the drum during the RB process, design the models of the main steam pressure rate corresponding to the change rate of the drum water level when the feed water pump RB an...

Embodiment 2

[0067] On the basis of Embodiment 1, Embodiment 2 of the present application provides the application of a method of Embodiment in a certain 330MW subcritical unit:

[0068] Design the model function of the main steam pressure rate and inertia time corresponding to the water level change rate of the drum, the non-feedwater pump RB working condition and the feedwater pump RB working condition are respectively detailed;

[0069] 1. Non-feed water pump RB working condition

[0070] The disturbance to the water level of the steam drum comes from the combustion of the boiler. The water level of the steam drum presents a trend of first falling, then rising, and finally falling to a stable value. According to its changing characteristics, it can be divided into three stages. The first stage is the falling stage, and the second stage is The rising stage, the third stage is gradually returning to a stable value after rising.

[0071] In the first stage, due to the weakening of evaporati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com