Intermittent production process fault detection method based on Markov chain and spectral clustering

A Markov chain and fault detection technology, applied in the fields of instrument, calculation, character and pattern recognition, etc., can solve the problems of unequal length and poor fault detection effect, so as to avoid the problem of data unequal length and avoid data interruption. Continuing problems, reducing the effects of clustering and fault detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

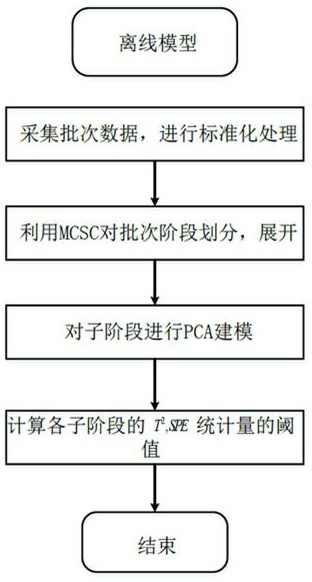

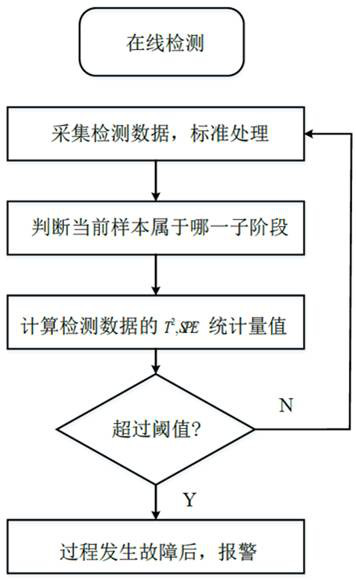

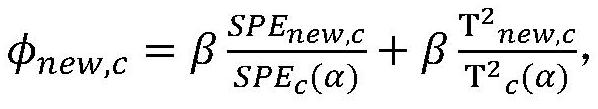

Method used

Image

Examples

Embodiment 1

[0043] In the embodiment of the present invention, the production process fault detection method based on Markov chain spectrum clustering is applied to the fault detection of the penicillin production process. Penicillin has been widely used in the medical field, and the production process of penicillin is a typical multi-stage, nonlinear, dynamic batch process.

[0044] There are a total of 6 input variables in the penicillin fermentation process, including ventilation rate, stirring power, medium feed flow rate, material temperature, acid-base flow acceleration rate, and cooling water flow acceleration rate. After fermentation, there will be 9 output variables, including: fermentation volume, heat production, carbon dioxide concentration, dissolved oxygen concentration, penicillin concentration, pH value, material concentration, microbial concentration and reactor temperature. Different variables can be adjusted by setting the initial parameters, such as adjusting the flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com