Finned radiator for efficient heat dissipation transformer

A heat sink and transformer technology, which is applied in the direction of transformer/inductor cooling, etc., can solve the problems of limiting the flow rate of transformer oil, small flow section of transformer oil, and backlog of oil, so as to increase the flow section area, improve heat dissipation effect, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

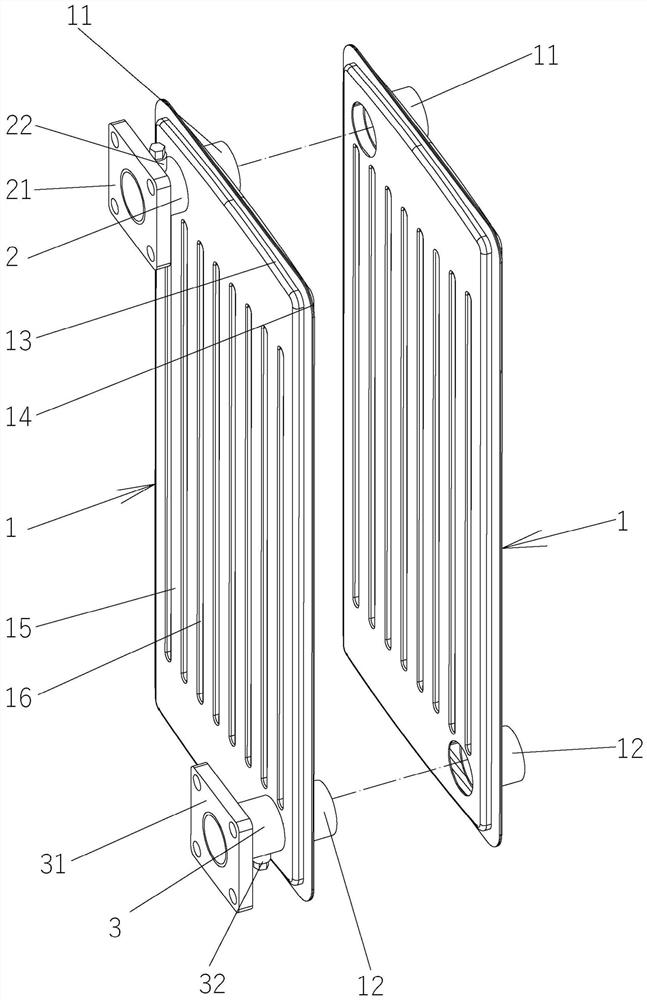

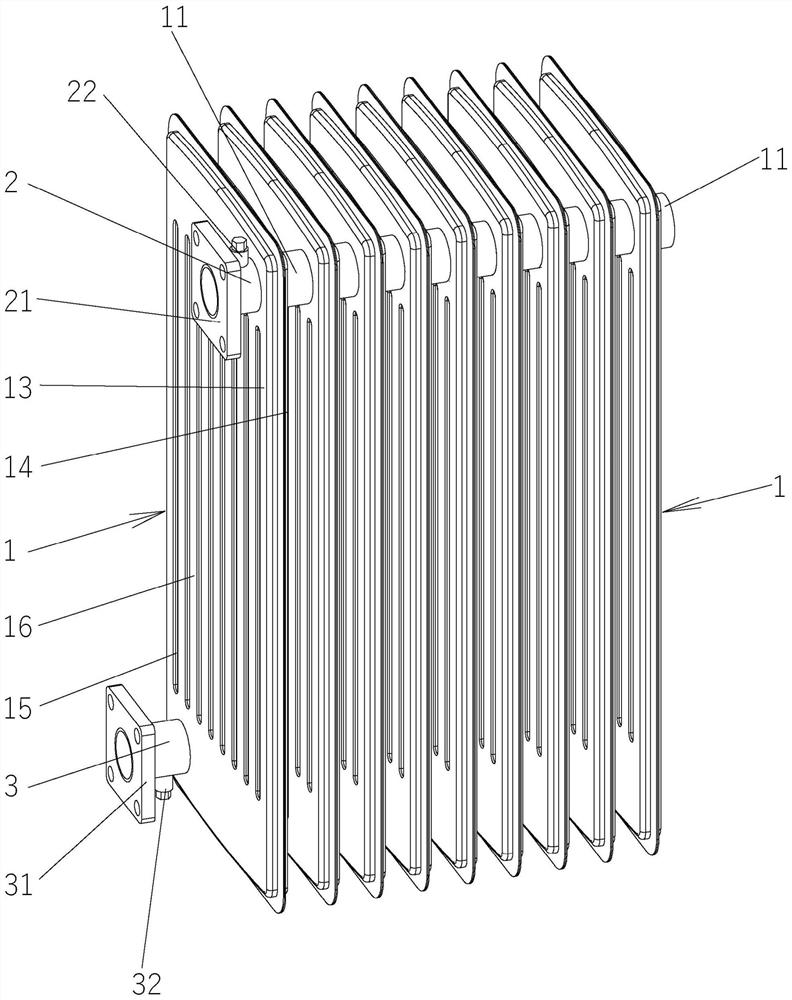

[0021] See figure 1 and figure 2 , which shows a high-efficiency heat dissipation finned radiator for transformers, including a group of heat sinks 1 arranged longitudinally parallel to each other and equidistant from each other. The plurality of heat sinks 1 are all hollow cuboid plate structures and formed inside There is an oil flow chamber.

[0022] As the technical gist of the technical solution provided by the present invention: a first connecting pipe 11 is sleeved at the edge of the body of the heat sink 1 near the top edge and close to the end of the long side of the heat sink 1 , and on the body of the heat sink 1 near the edge of the bottom edge and at the position close to the other long side of the heat sink 1, a second connecting pipe 12 is sleeved, and two adjacent heat sinks 1 pass through the two ends The first connecting pipes 11 and the second connecting pipes 12, which are both provided with openings, communicate with each other, and the positions of the...

Embodiment 2

[0029] In this embodiment, by image 3 and Figure 4 As shown, the first connecting pipe 11 is arranged at the right position close to the top edge of the heat sink 1 , and the second connecting pipe 12 is arranged near the bottom edge of the heat sink 1 At the left part of the edge, an oil circulation circuit with an upper right lower left structure is formed on a group of multiple cooling fins 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com