Sandy cultivated land soil body construction method using straws

A construction method and straw technology, applied in the direction of soil preparation methods, applications, agricultural machinery and tools, etc., can solve the problems of waste of resources, environment, random accumulation and abandonment, pollution, etc., to promote accumulation, improve soil structure, and prevent water seepage leaky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

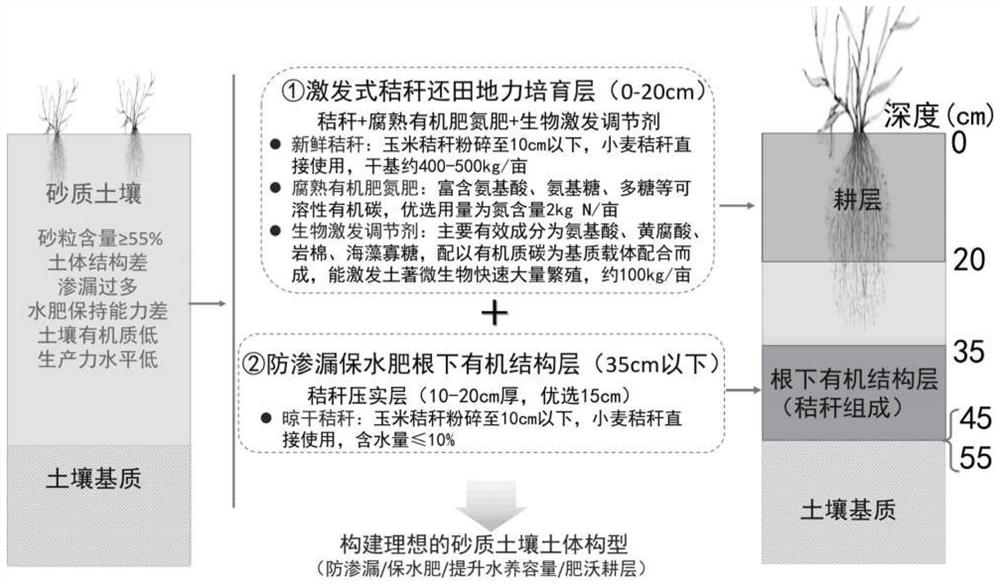

[0033] A sandy cultivated soil construction method using straw, see figure 1 , including the following steps:

[0034] Step 1. After the crops are harvested, the corn stalks and wheat straws are processed: the corn stalks are crushed to no more than 10cm by a straw grinder, and the wheat straws are directly returned to the field; 20-80% of the wheat straws are kept fresh, and 20-80 % Wheat stalks are dried to a water content below 10%;

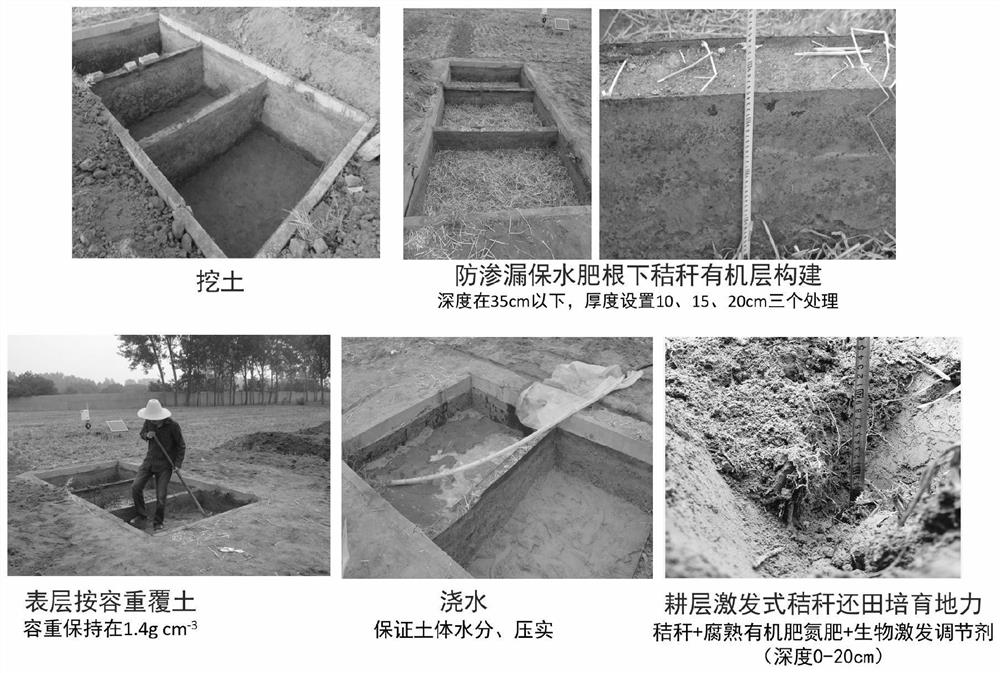

[0035] Step 2, burying the dried straw into the soil to a depth greater than 35cm, and compacting the straw until the thickness of the straw is 10-20cm, that is, the depth of the straw layer in the soil is 35-55cm;

[0036] Step 3, water after covering the soil at a depth of 0-35cm to ensure soil moisture and compaction so that the soil bulk density of this layer is 1.3-1.6g cm -1 ;

[0037] Step 4. Mix the fresh wheat straw evenly with decomposed organic fertilizer nitrogen fertilizer. The decomposed organic fertilizer nitrogen fertilizer ...

Embodiment 2

[0041] (1) Materials and methods

[0042] 1. General situation of the test area and properties of the test soil

[0043]The test site is located in Fengqiu National Experimental Station of Agricultural Ecosystem of Chinese Academy of Sciences in Fengqiu County, Henan Province (35°01′N, 114°32′E). This area belongs to the semi-arid and semi-humid warm temperate monsoon climate, with an average annual precipitation of 615mm, 67% of which is concentrated in June-September; the average temperature is 13.9°C, the lowest monthly average temperature is -1.0°C in January, The average temperature is 27.2°C, which occurs in July. The soil in this area developed as the alluvial soil of the Yellow River, and the sandy soil with high sand content in this area was selected for the test. The basic property indicators of the soil are shown in Table 1.

[0044] Table 1 Basic properties of test soil

[0045]

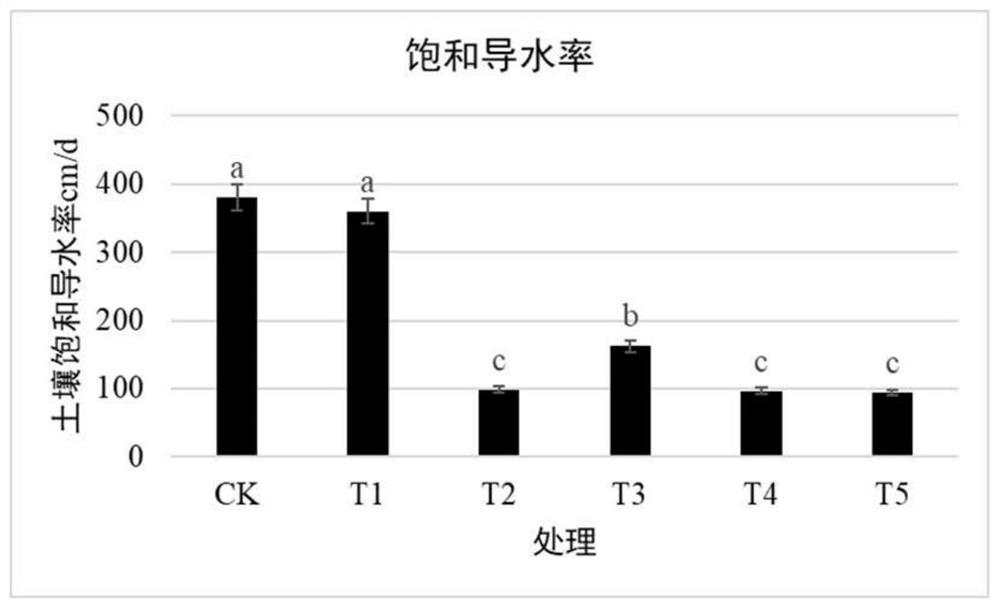

[0046] 2. Test treatment

[0047] A total of 6 treatments were designed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com