Micro-fluidic distribution chip

A microfluidic and chip technology, applied in laboratory utensils, laboratory containers, chemical instruments and methods, etc., can solve problems such as accurate analysis of adverse reaction results, cross-contamination of reaction pools, and limited distribution, and achieve the goal of making Convenience, simple structure, and the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

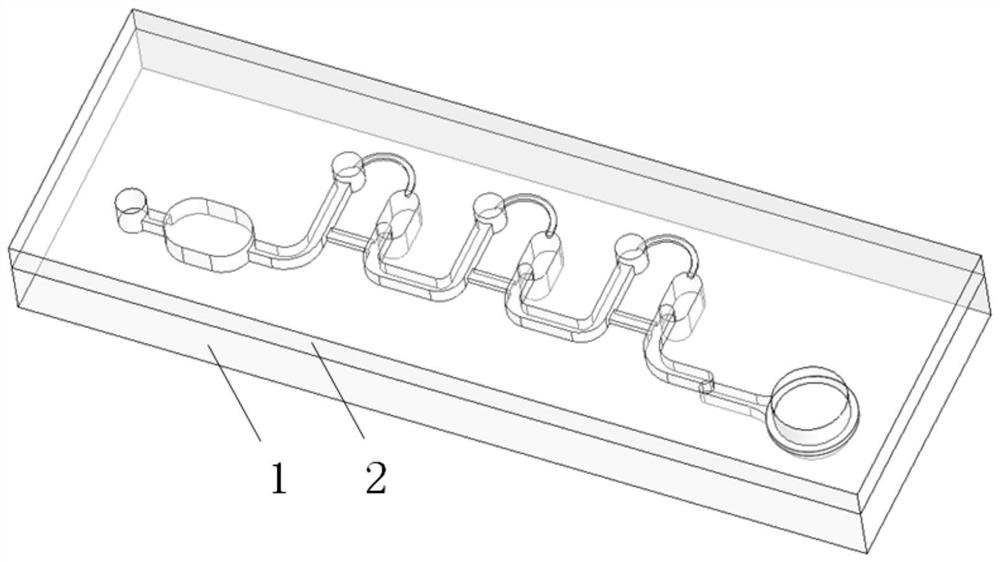

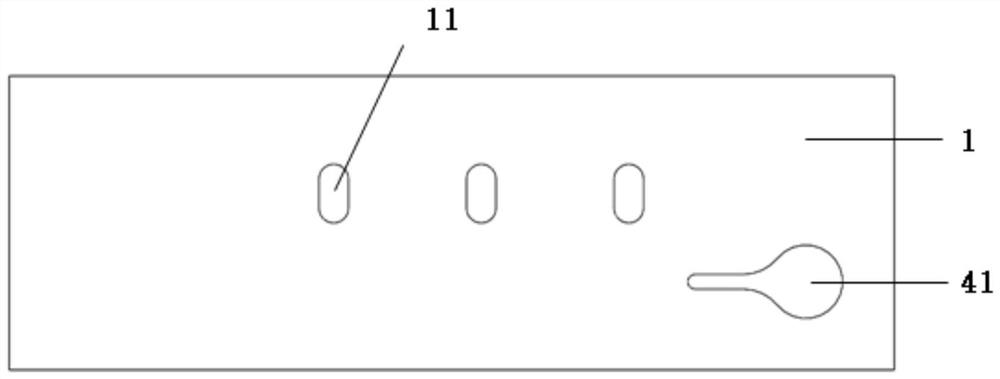

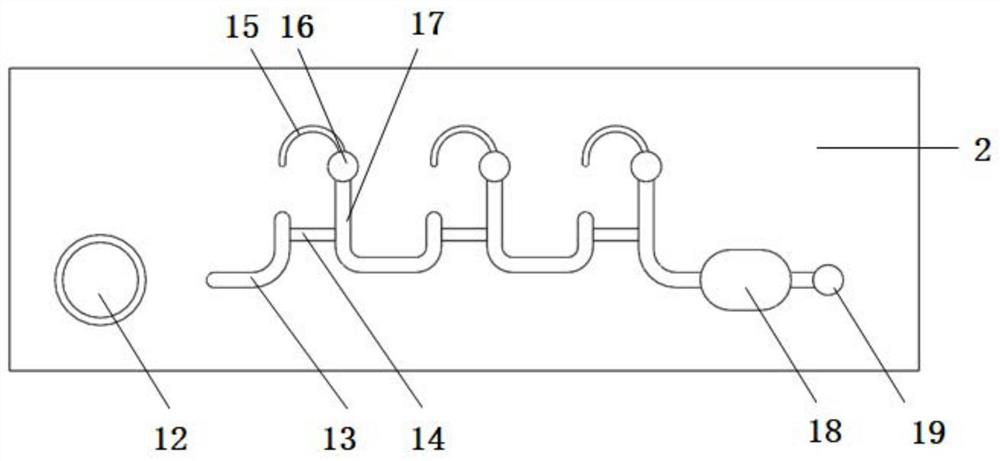

[0033] see Figure 1-Figure 4 , the microfluidic dispensing chip provided in this embodiment includes a chip body 1 and a cover plate 2, and the chip body 1 and the cover plate 2 can be realized by means of double-sided adhesive bonding, thermocompression bonding, ultrasonic welding, laser welding, etc. Seal fit. The chip body 1 is provided with a dispensing cavity 11 , and the cover plate 2 is provided with a sample injection hole 12 , a sample inlet pipe 13 , a bypass pipe 14 , an exhaust pipe 15 , a sample outlet pipe 17 , and an exhaust hole 19 . The sample injection hole 12 , the sample injection pipeline 13 , the distribution chamber 11 , the exhaust pipeline 15 , the sample outlet pipeline 17 , and the exhaust hole 19 are connected in sequence, and the bypass pipeline 14 is connected to the sample inlet pipeline 13 and the sample outlet pipeline 17 .

[0034] The distribution chamber 11 on the chip body 1 and the sample inlet pipe 13 on the cover plate 2, the bypass pi...

Embodiment 2

[0042] Figure 5 and Image 6 Schematically shows the second embodiment of the microfluidic chip provided by the present invention, the microfluidic chip provided by the second embodiment has roughly the same structure as the microfluidic chip provided by the first embodiment, wherein Structures with similar functions are given similar reference numerals, and for the sake of brevity, only the differences are described in detail here.

[0043] Different from the first embodiment, in the second embodiment, all the pipes and cavities are arranged on the chip body 1, that is, the distribution chamber 21, the filter chamber 41, the sample injection hole 22, the sample injection pipe 23, the row Air pipe 25, sample outlet pipe 27, exhaust hole 29, bypass pipe 24 and interface valve 26 are all arranged on the chip body 1. When the depth of the sample inlet pipe 23 and the distribution chamber 21 at the same level are different, in order to avoid A sudden change in the depth of the ...

Embodiment 3

[0045] Figure 7 Schematically shows the third embodiment of the microfluidic chip provided by the present invention, the microfluidic chip provided by the third embodiment has roughly the same components and connections as the microfluidic chip provided by the first embodiment In the relationship, structures with similar functions are given similar reference numerals, and for the sake of brevity, only the differences are described in detail here.

[0046] Different from the first embodiment, in the third embodiment, all the pipes and cavities are arranged on the chip body 1, that is, the distribution chamber 31, the filter chamber 41, the sampling hole 32, the sampling pipe 33, the row Gas pipe 35, sample pipe 37, exhaust hole 39, bypass pipe 34 and interface valve 36 are all arranged on the chip body 1, which is different from the change control of pipe cross-sectional area in the first embodiment and the second embodiment. Flow resistance, this embodiment realizes the orde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com