Vinegar paste

A technology of vinegar ointment and vinegar juice, which is applied in the fields of vinegar ointment and food vinegar ointment, which can solve the problems such as the reduction of medicinal value of vinegar ointment, and achieve the effects of improving cardiovascular and cerebrovascular diseases, regulating blood pressure and blood sugar, and sticky taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

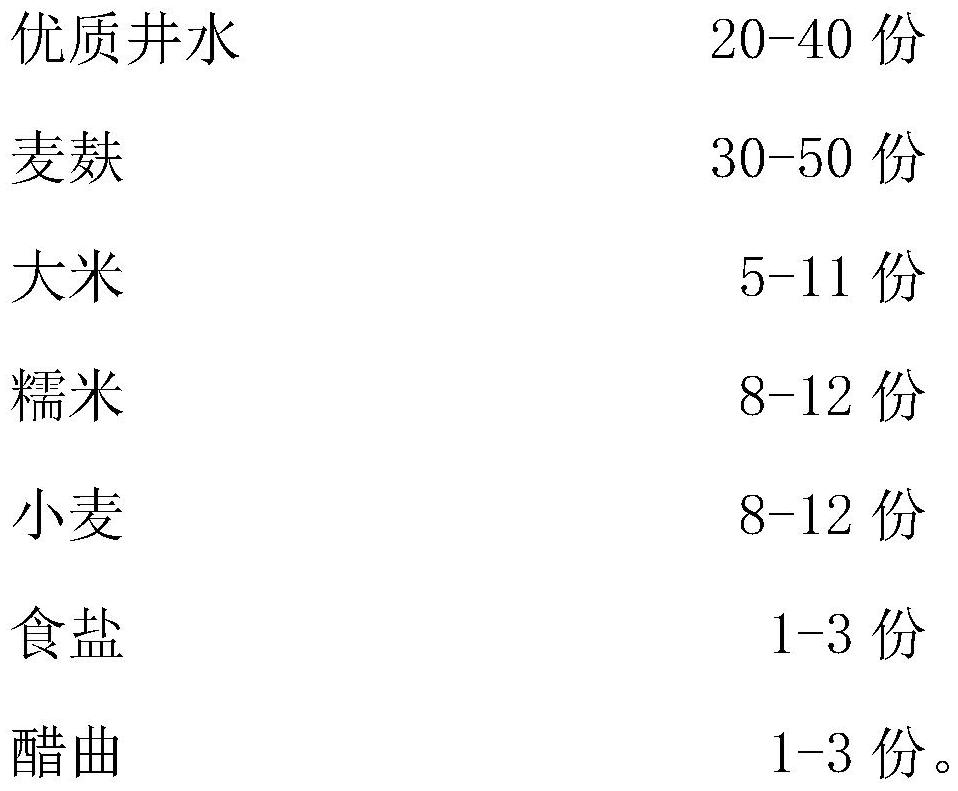

[0023] The present invention provides a kind of vinegar ointment, embodiment one: comprise and be made up of the composition of following parts by weight:

[0024]

[0025] Wherein, the processing technology of described food vinegar paste is as follows:

[0026] Step 1: Pour the wheat bran and wheat into the holding pot, quickly stir-fry at a temperature of 100-150 degrees Celsius, then pour the vinegar koji in its uncooled state, and then put it in the cellar, and put it into the fermentation tank After sealing, obtain vinegar juice A through 20-25 days of fermentation through a filter sieve;

[0027] Step 2: First wash the rice and glutinous rice, pour them into a container and put them in an equal proportion of high-quality well water for soaking. The water surface is 15 cm above the rice layer, and then soak at a constant temperature of 25 degrees Celsius for 8-10 hours; - 2 times water;

[0028] Step 3: Cook the rice and glutinous rice in Step 2 for 30-40 minutes, p...

Embodiment 2

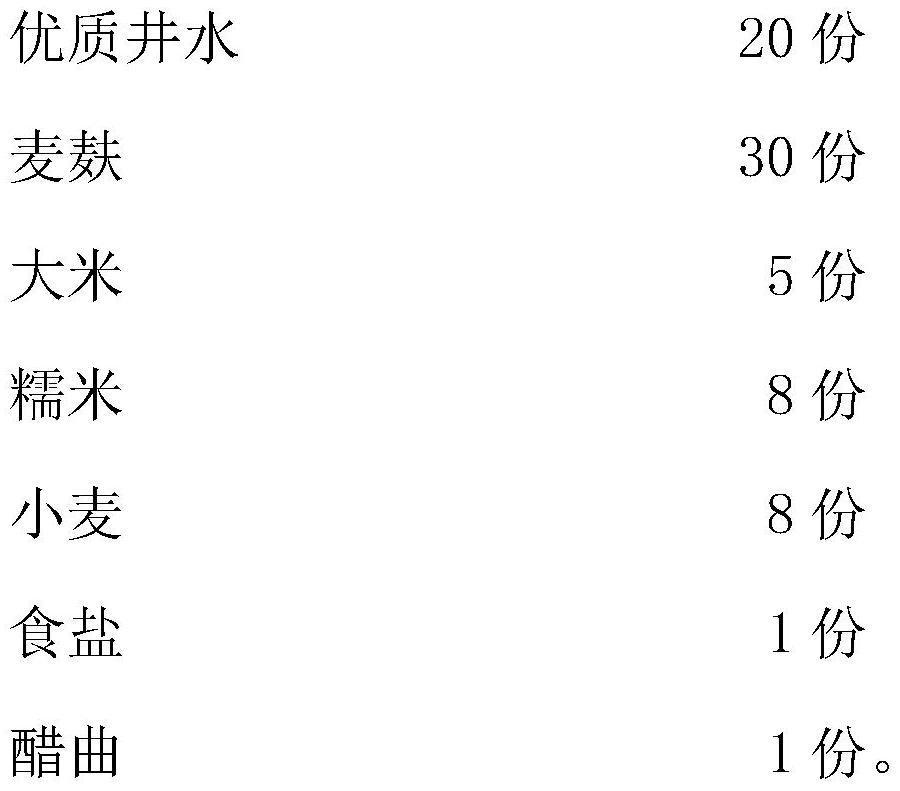

[0034] Embodiment two: comprise and be made up of the composition of following parts by weight:

[0035]

[0036] Wherein, the processing technology of described food vinegar paste is as follows:

[0037] Step 1: Pour the wheat bran and wheat into the holding pot, quickly stir-fry at a temperature of 100-150 degrees Celsius, then pour the vinegar koji in its uncooled state, and then put it in the cellar, and put it into the fermentation tank After sealing, obtain vinegar juice A through 20-25 days of fermentation through a filter sieve;

[0038] Step 2: First wash the rice and glutinous rice, pour them into a container and put them in an equal proportion of high-quality well water for soaking. The water surface is 15 cm above the rice layer, and then soak at a constant temperature of 25 degrees Celsius for 8-10 hours; - 2 times water;

[0039] Step 3: Cook the rice and glutinous rice in Step 2 for 30-40 minutes, pour an appropriate amount of water into the rice during the...

Embodiment 3

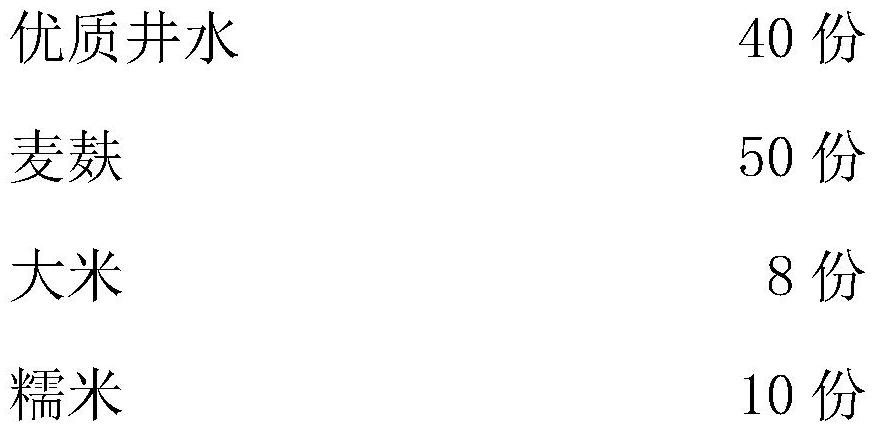

[0045] Embodiment three: comprise the composition that is made up of following parts by weight:

[0046]

[0047] Wherein, the processing technology of described food vinegar paste is as follows:

[0048] Step 1: Pour the wheat bran and wheat into the holding pot, quickly stir-fry at a temperature of 100-150 degrees Celsius, then pour the vinegar koji in its uncooled state, and then put it in the cellar, and put it into the fermentation tank After sealing, obtain vinegar juice A through 20-25 days of fermentation through a filter sieve;

[0049] Step 2: First wash the rice and glutinous rice, pour them into a container and put them in an equal proportion of high-quality well water for soaking. The water surface is 15 cm above the rice layer, and then soak at a constant temperature of 25 degrees Celsius for 8-10 hours; - 2 times water;

[0050] Step 3: Cook the rice and glutinous rice in Step 2 for 30-40 minutes, pour an appropriate amount of water into the rice during the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com