Blast furnace material type identification method, device and system based on image multivariate features

A recognition method and image technology, applied in character and pattern recognition, instruments, computer parts, etc., can solve the problem of low recognition accuracy of blast furnace material, and achieve the effect of great application value, high accuracy and good real-time performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

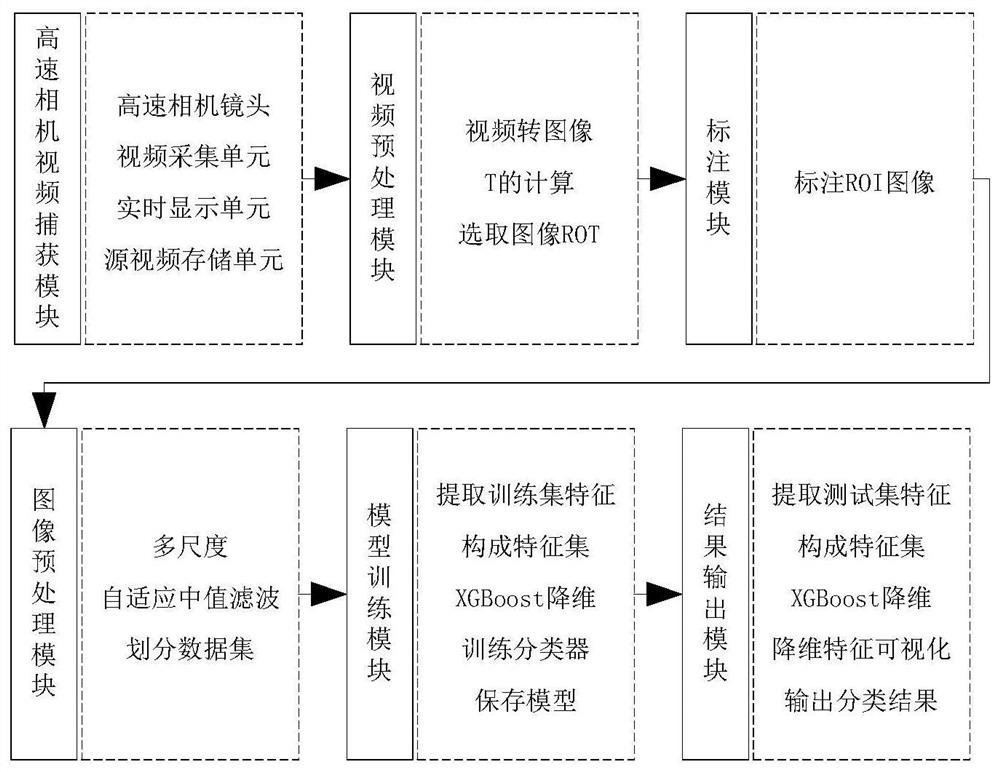

[0067] The method for identifying blast furnace materials based on image multivariate features provided in Embodiment 1 of the present invention includes:

[0068] Step S101, collecting a high frame rate material transportation video, and converting the high frame rate material transportation video into a frame image;

[0069] Step S102, selecting the area in the frame image that includes the material horizontal area in the entire area as the material area image;

[0070] Step S103, extracting multivariate features of the image of the material area, the multivariate features include color features, texture features, grayscale features and material density distribution features;

[0071] In step S104, a classifier is trained according to the multivariate features of the material area image, and the blast furnace material type is identified according to the trained classifier.

[0072] The blast furnace material type identification method based on image multiple features provid...

Embodiment 2

[0074] The method for identifying blast furnace species based on image multivariate features provided in Embodiment 2 of the present invention includes:

[0075] S1: Use a high-speed camera to capture the material transportation status of the blast furnace feeding belt, and obtain a high frame rate material transportation video;

[0076] S2: Convert the high frame rate material transportation video into a frame image, extract the ROI image area of the frame image, and perform multi-scale adaptive median filtering on the ROI image area to obtain the preprocessed material area image;

[0077] S3: Carry out image classification, recognition and labeling on the preprocessed material area image to obtain the label image, and divide the label image into a training set and a test set;

[0078] S4: Extract the color features, texture features, grayscale features and density distribution features of the images in the training set, and train a classifier according to the color feature...

Embodiment 3

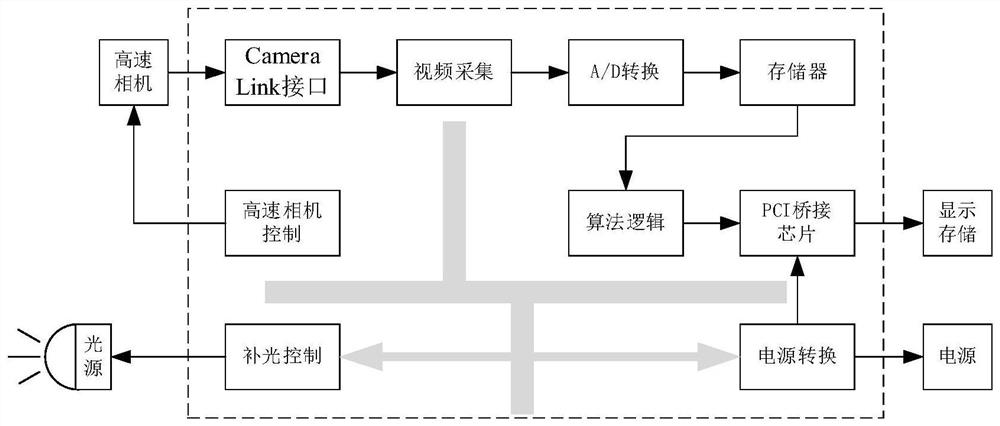

[0130] The specific embodiment of the present invention is further described in conjunction with the accompanying drawings, and the embodiment of the present invention is applied to a 2650m 3 On the feeding system of the blast furnace, on the feeding belt of the feeding system according to Figure 4 Install high-speed cameras and other devices. In terms of camera selection, the most important thing is the parameter selection of frame rate and resolution. A suitable frame rate can capture the transportation status of materials, and sufficient resolution can provide more detailed information on the image. In order to meet the above conditions, the industrial camera has a resolution of 1280×720 and a frame rate of 240.

[0131] Depend on Figure 4 It can be seen that the device includes a high-speed camera bracket, a high-speed camera protective shell, a high-speed camera cleaning device, a high-speed camera, a conveyor belt, materials to be identified, a video acquisition unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com