Power self-optimization method of solid-state laser

A solid-state laser, self-optimization technology, applied in the direction of lasers, laser components, phonon exciters, etc., can solve problems affecting the use of solid-state lasers, laser power fluctuations, etc., to achieve the effect of automatic optimization adjustment and stable optical power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described below.

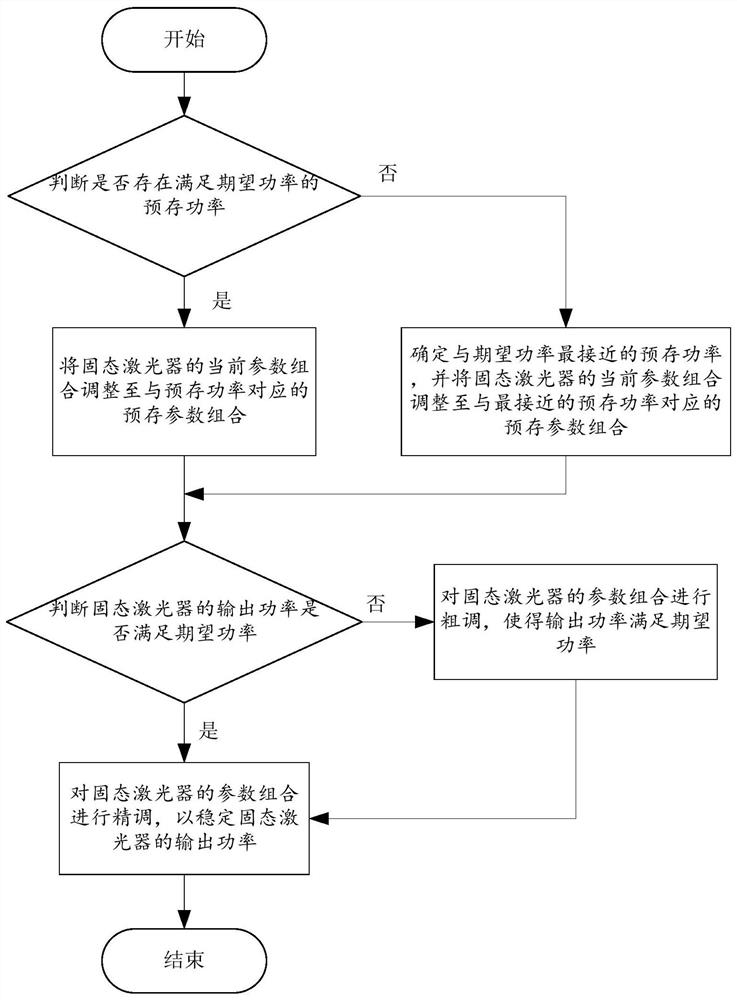

[0030] A method for power self-optimization of a solid-state laser, comprising:

[0031] S1, the control system judges whether there is pre-stored power that meets the expected power according to the expected power.

[0032] S2, if it exists, the control system adjusts the current parameter combination of the solid-state laser to the pre-stored parameter combination corresponding to the pre-stored power; otherwise, the control system determines the pre-stored power closest to the expected power, and adjusts the current parameter combination of the solid-state laser to The stored parameter combination corresponding to the closest stored power.

[0033] Preferably, the method for determining the combination of pre-stored parameters includes:

[0034] Determine the pre-stored power, the pre-stored power is not greater than the maximum output power of the solid-state laser;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com