Japonica rice gamma-aminobutyric acid low-pressure steam enriching and drying combined process test method

An aminobutyric acid and low-pressure steam technology, applied in the agricultural field, can solve the problems of affecting quality, mildew and deterioration of paddy, loss of nutrients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

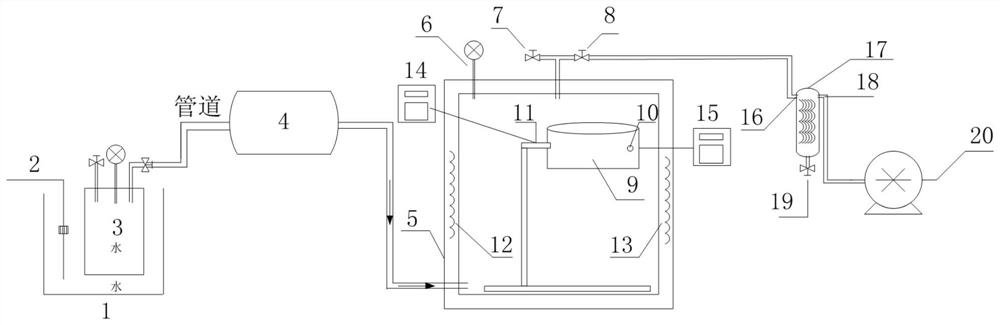

[0062] Such as figure 1 As shown, the test bench for the effect of low-pressure steam enrichment and drying combined process on the content of GABA in japonica rice includes water bath 1, water bath constant temperature heater 2, vacuum barrel 3, superheater 4, drying oven 5, pressure gauge 6, Vent valve 7, air extraction port 8, material rack 9, temperature sensor 10, medium weight sensor 11, first aluminum foil heater 12, second aluminum foil heater 13, weighing system 14, temperature detection system 15, condenser air inlet 16. Condensation steam-water separator 17, condenser gas outlet 18, drain port 19 and vacuum pump 20; water bath constant temperature heater 2 and vacuum barrel 3 are located in water bath 1, vacuum barrel 3 is connected with superheater 4, and superheater 4 is connected with drying The chamber of box 5 communicates, and the first aluminum foil heater 12 and the second aluminum foil heater 13 are outside the chamber of drying box 5, and the material rack...

Embodiment 2

[0064] Using the enrichment and drying experimental platform system in Example 1, the experiment on the effect of low-pressure steam enrichment and drying combination process on the content of γ-aminobutyric acid in japonica rice was carried out; the japonica rice used in the test was Suijing 18 produced in 2020, produced by Donghe Jingu in Qing'an Provided by Grain Reserve Co., Ltd.; test reagent γ-aminobutyric acid (≥99.9%) was produced by Sigma, and sodium hypochlorite, redistilled phenol, ethanol and sodium tetraborate were produced by Sinopharm Chemical Reagent Co., Ltd.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com