Back-up roll device of plate and strip cold-rolling mill

A technology for cold rolling mills and back-up rolls, which is applied in the direction of counter pressure devices, metal rolling stands, metal rolling mill stands, etc., and can solve problems such as high bearing temperature, oil leakage at the rotating seal, and large consumption of seals, etc. Achieve the effect of meeting the needs of roll rotation, ensuring lubrication and cooling, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

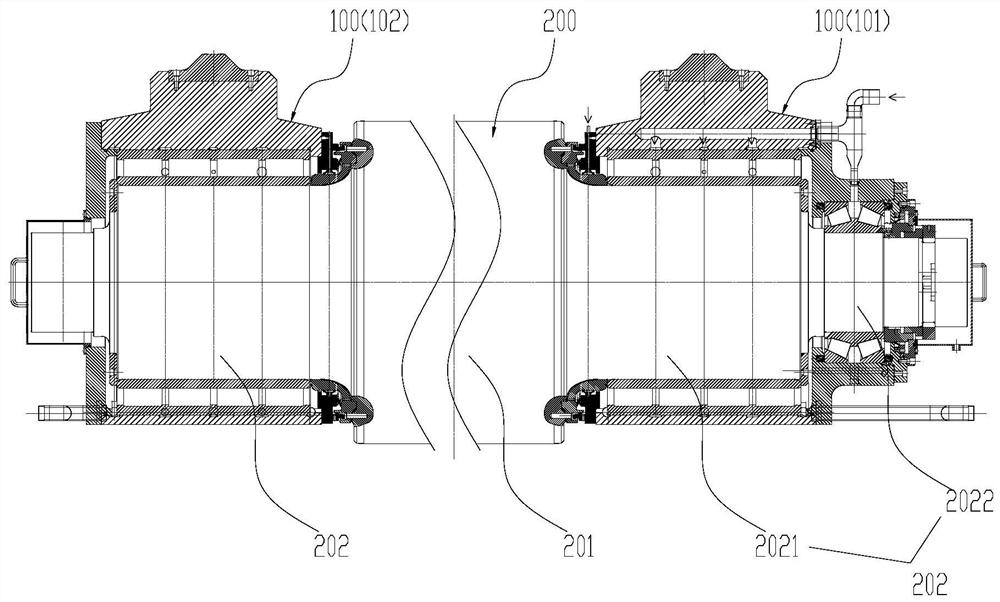

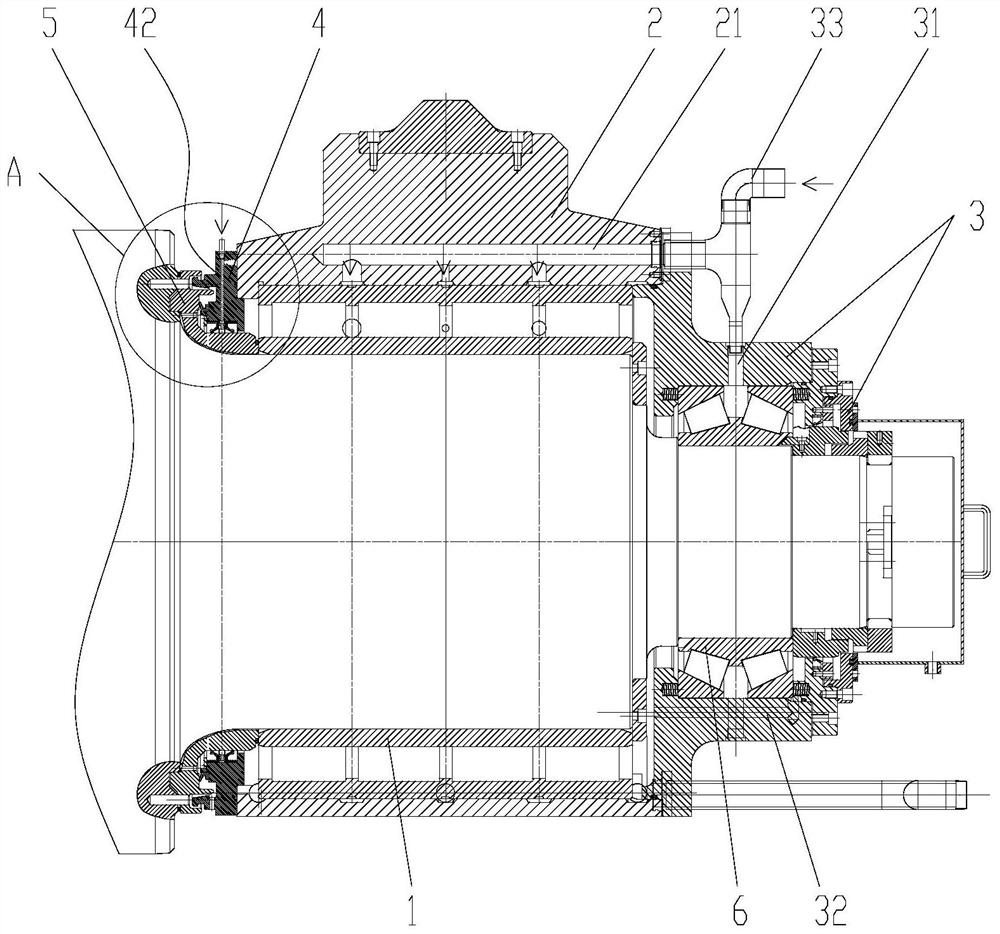

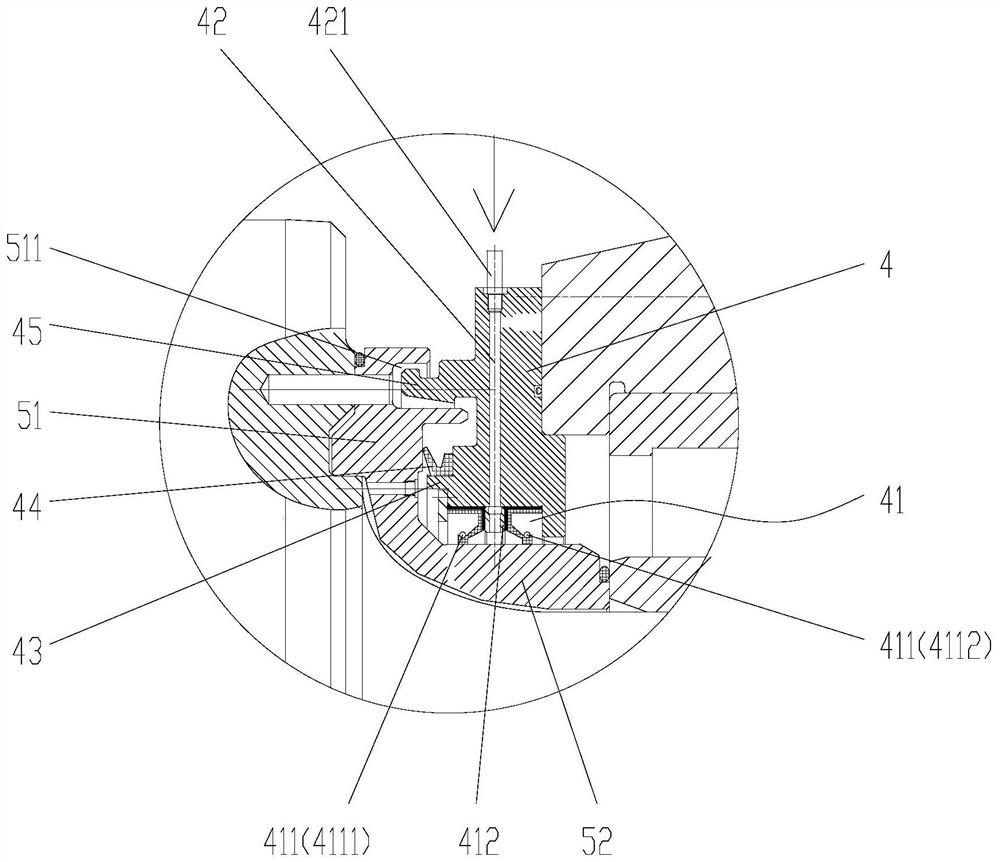

[0041] Such as Figure 1 to Figure 9As shown, this embodiment provides a back-up roll device for a strip cold rolling mill, including a roll 200 and a bearing seat assembly device 100, and the bearing seat assembly device 100 includes a radial bearing 1, a bearing seat 2, an outer end cover 3 and an inner end cover The cover 4 and the radial bearing 1 are sleeved on the roll neck 202 at one end of the roll 200 , the bearing housing 2 is sleeved on the radial bearing 1 , and the outer end cover 3 is fixed on the outer end of the bearing housing 2 . The inner end cover 4 is fixed on the inner side of the bearing seat 2 and sleeved on the roll neck 202 .

[0042] The top of the bearing seat 2 is provided with a first thin oil lubri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com