Pumping unit capable of achieving intermittent pumping through non-full-cycle motion of crank without shutdown

A non-circumferential, pumping unit technology, used in production fluids, wellbore/well components, earthmoving, etc., to solve problems such as lack of flow or agitation, inability to adjust the pumping unit stroke in a large range, wellhead freezing and blocking, etc. , to achieve the effect of saving equipment costs, avoiding dry pumping, and reducing oil pumping speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

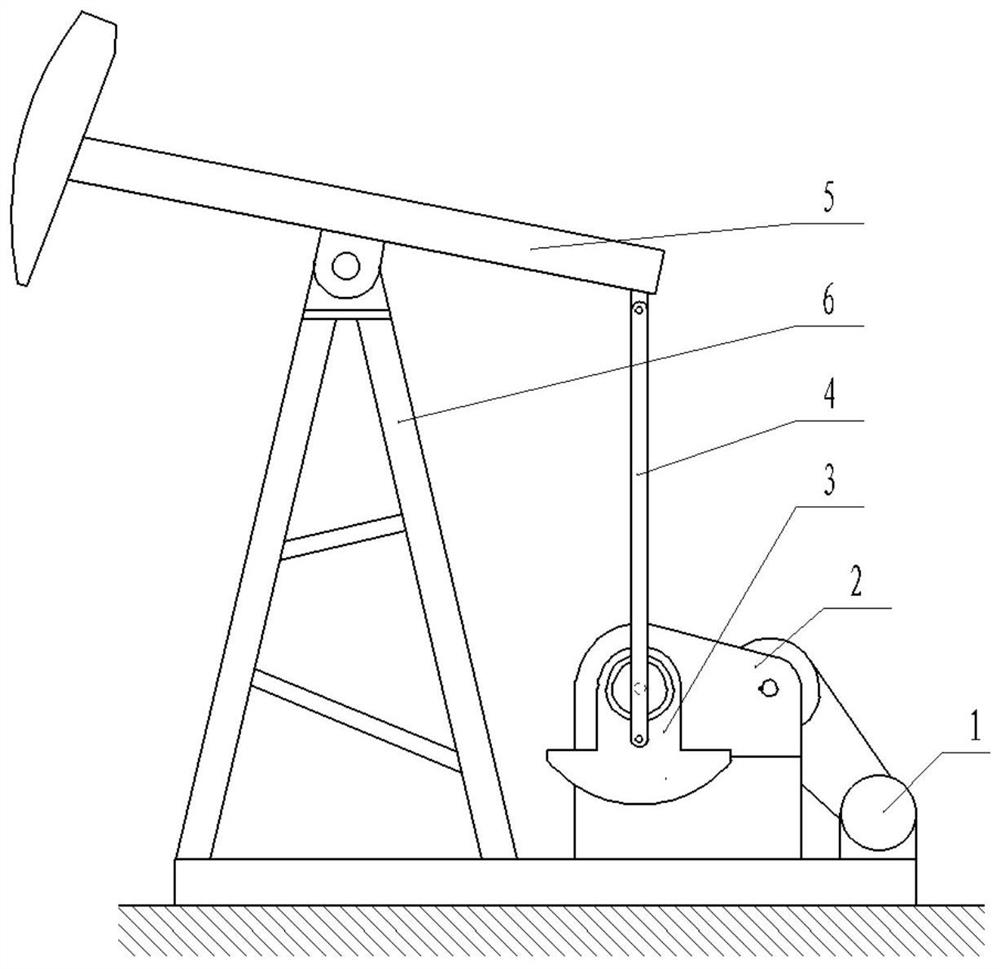

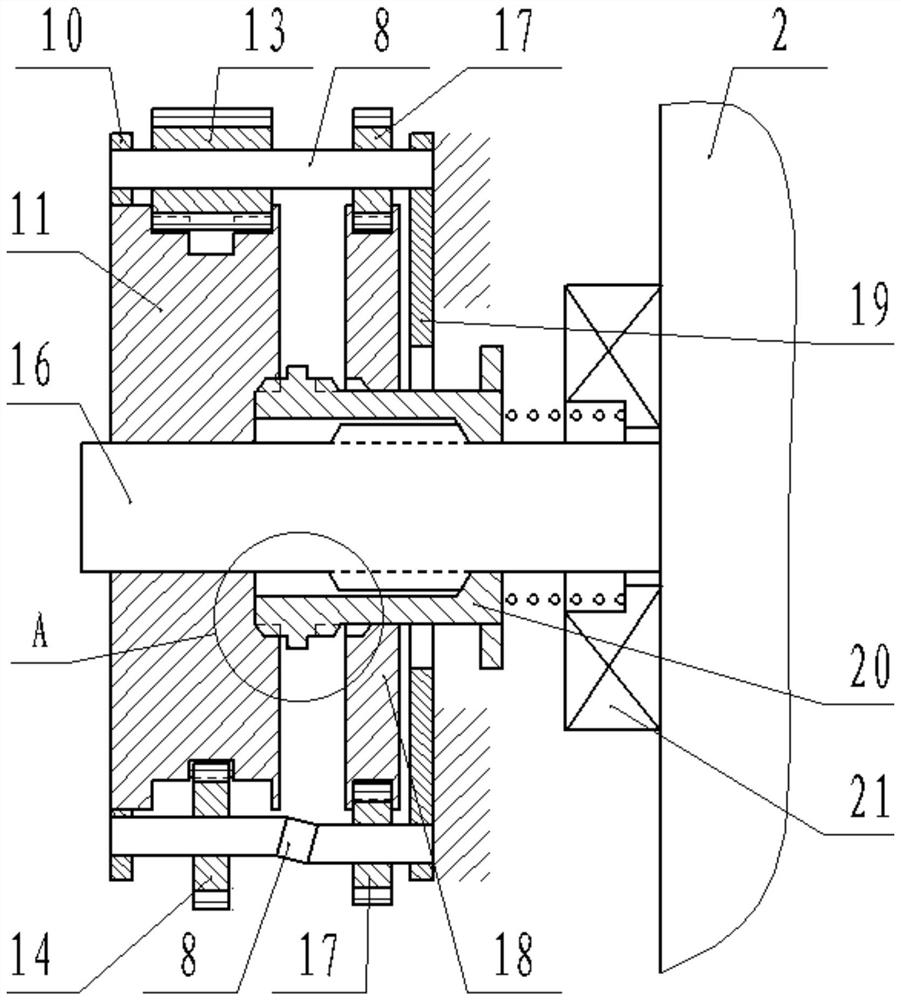

[0034] Such as figure 1 As shown, the present embodiment includes a motor 1, a reducer 2, a crank assembly 3, a connecting rod 4, a beam 5 and a bracket 6, the motor 1 is connected with the input shaft of the reducer 2 through a belt transmission mechanism, and the crank assembly 3 The end is installed on the output shaft 16 of the reducer 2 and rotates under the drive of the reducer 2. The middle part of the beam 5 is hinged on the top of the bracket 6. The upper and lower ends of the connecting rod 4 are respectively hinged on the tail of the beam 5 and the On the crank assembly 3. When working, the power provided by the motor 1 is transmitted to the reducer 2, and then converted into the rotary motion of the crank assembly 3, and the rotary motion of the crank assembly 3 is converted into the reciprocating swing of the beam 5 through the connecting rod 4. The above structure is a conventional structure in the prior art, and will not be repeated here.

[0035] The innovati...

Embodiment 2

[0045] The difference between this embodiment and the first embodiment lies in that the numbers of the inner gear teeth segments 9 and the outer gear teeth segments 12 are different.

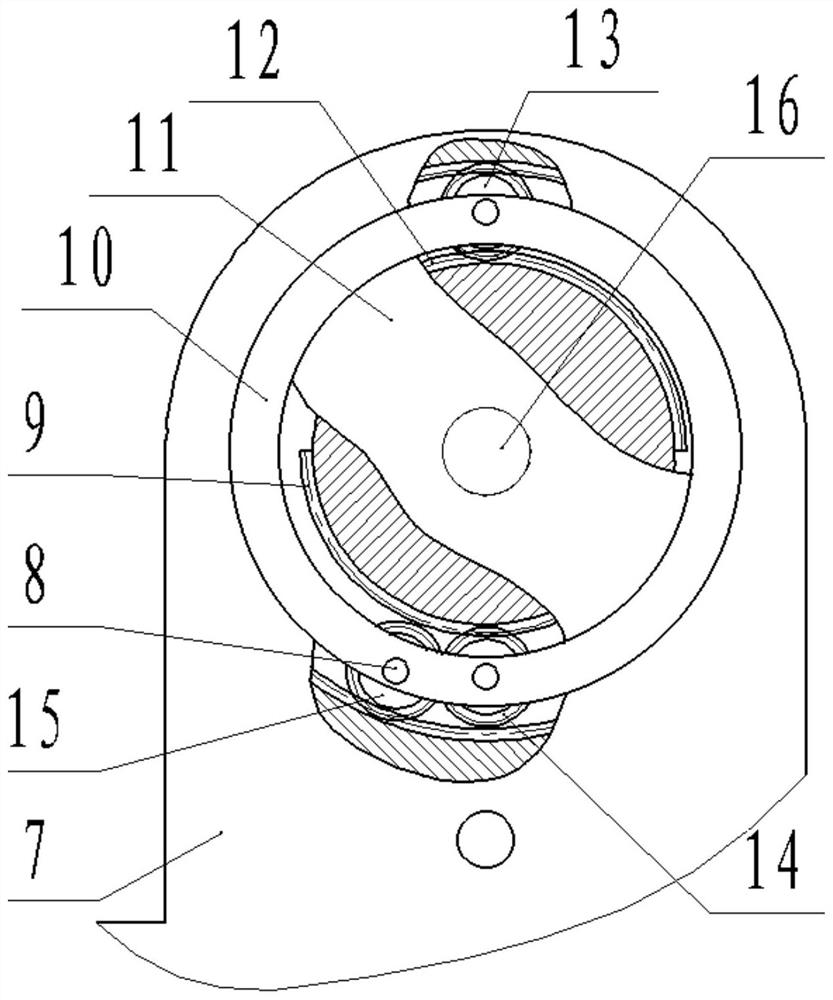

[0046] Such as Figure 5 , 8 , 9, there are two inner gear teeth segments 9 and outer gear teeth segments 12, and the inner gear teeth segments 9 and outer gear teeth segments 12 are alternately arranged on the circumference of the second sun gear 11, each The coverage angles of each inner gear tooth section 9 and each outer gear tooth section 12 are 90 degrees, and the inner gear tooth section 9 and the outer gear tooth section 12 are on a plane perpendicular to the axis 8 of the second sun gear 11 The projected dislocations form a 360 circle.

[0047] Compared with the first embodiment, the advantage of this embodiment is that the swing range of the crank body 7 is smaller, and the unnecessary wear on the plunger of the oil well pump is smaller.

Embodiment 3

[0049] The difference between the embodiment and the first embodiment lies in that the numbers of the inner gear teeth segments 9 and the outer gear teeth segments 12 are different.

[0050] Such as Figure 5 , 10 , 11, there are two inner gear tooth sections 9 and outer gear tooth sections 12, and the inner gear tooth sections 9 and the outer gear tooth sections 12 are arranged alternately on the circumference of the second sun gear 11, each The coverage angles of each inner gear tooth section 9 and each outer gear tooth section 12 are 90 degrees, and the inner gear tooth section 9 and the outer gear tooth section 12 are on a plane perpendicular to the axis 8 of the second sun gear 11 The projected dislocations form a 360 circle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com