Air-cooling heat dissipation method for digital generator

A technology of digital generator and heat dissipation method, which is applied to the cooling of engines, engine components, machines/engines, etc., can solve the problems of difficulty in ensuring the overall life of the engine, reducing the cooling effect of the engine, and improving the cooling effect. Heat dissipation and cooling effect, scientific cooling path design, and the effect of improving work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

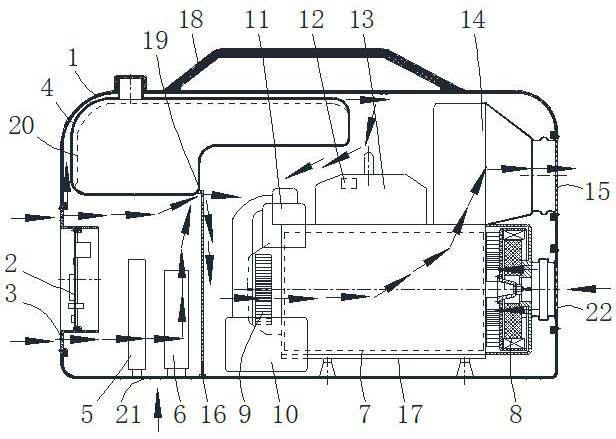

[0065]Embodiment 1: An air-cooled heat dissipation method for a digital generator. In this method, a partition is used to divide the inner cavity of the generator case into a low-temperature area on the left and a high-temperature area on the right, and the air flow is guided from the low-temperature area at the left end of the case. After the air inlet enters, it first flows through the control panel, the controller and the current conversion module (in practice, the current conversion module is a rectifier bridge or an inverter), and then enters the high temperature area on the right through the partition. The improvement is that the high temperature on the right In the area, an engine casing is set at intervals outside the engine main body. The hand-pulled fan as the air flow power is located inside the opening of the left end of the engine casing, so that the air flow in the high temperature area passes through the carburetor and the engine cylinder head outside the engine c...

Embodiment 2

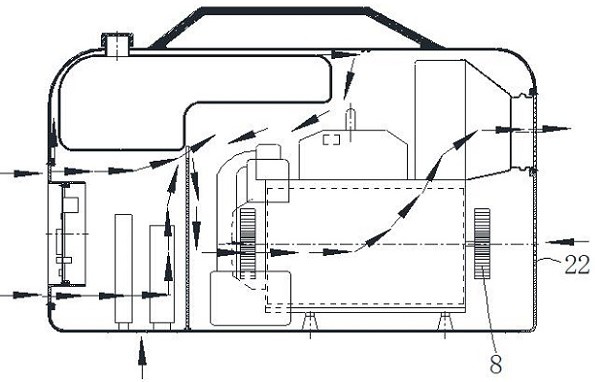

[0092] Embodiment 2, the difference between this embodiment 2 and embodiment 1 is that the figure 2 The digital generator implementation shown. figure 2 The digital generator shown and figure 1 The structures of the digital engines shown are mostly the same, and the only difference is that the installation positions of the generators are different. figure 2 In the digital generator shown, the generator is installed at the left end of the engine (not shown in the figure), and at the same time, the main shaft of the engine is rotatably passed through the engine casing to the right and an auxiliary fan 8 is installed, and the right end surface of the casing is facing the auxiliary fan 8 is provided with auxiliary tuyere 22.

[0093] In this way, it is possible to rely on the auxiliary fan to take in or out the air, so as to improve the cooling effect on the internal components of the chassis shell. During implementation, a second partition part can also be installed at the ...

Embodiment 3

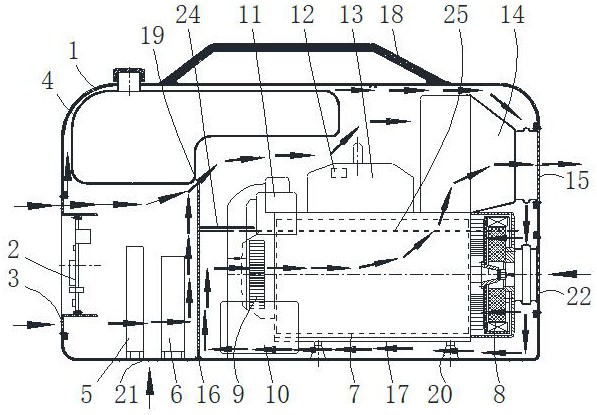

[0094] Embodiment 3, the difference between this embodiment 3 and embodiment 1 is that the image 3 and Figure 4 The digital generator implementation shown. image 3The digital generator shown includes a case shell 1, a control panel 2 is installed in the middle and lower part of the left end surface of the inner cavity of the case shell 1, and a main air inlet 3 is arranged on the case shell corresponding to the control panel 2, and a main air inlet 3 is installed on the upper left part of the inner cavity of the case shell. There is an oil tank 4, a controller 5 and a current conversion module 6 are installed on the lower left part of the inner cavity of the chassis shell 1 (in practice, the current conversion module is a rectifier bridge or an inverter), and an engine 7 is installed on the lower right part of the inner cavity of the chassis shell , the generator 8 is installed on the engine 7, the left end of the engine 7 is provided with a hand-pull fan 9, the air filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com