Colorimetric food freshness intelligent indication label and preparation method thereof

A freshness and food technology, applied in stamps, instruments, identification devices, etc., can solve the problems of harmful raw material environment, biological indicator labels can not guarantee the color rendering effect and stability at the same time, and achieve the improvement of hydrophobicity, integrity and display. Color protection, high hydrophobic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Step 1: Put 0.5g of anthocyanin powder into a beaker, add 10ml of deionized water, and stir with a magnetic stirrer for 30 minutes at room temperature, so that the anthocyanin powder is fully mixed in deionized water to obtain an anthocyanin solution; 0.5 g of glycerin was added dropwise to 5 g of CNFs suspension, and then stirred at room temperature for 30 minutes to obtain a film-forming base solution; 0.8 ml of anthocyanin solution and 4 ml of film-forming base solution were mixed to obtain a mixed solution.

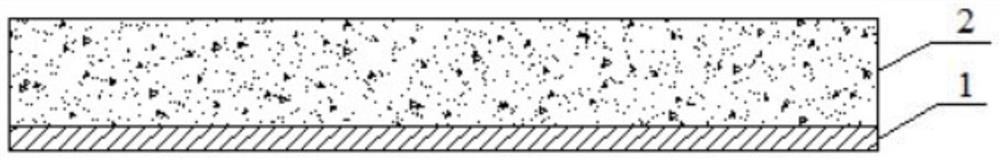

[0054] Step 2: Pour the mixed solution into a polytetrafluoroethylene mold to obtain a cellulose-anthocyanin porous film, such as image 3 shown.

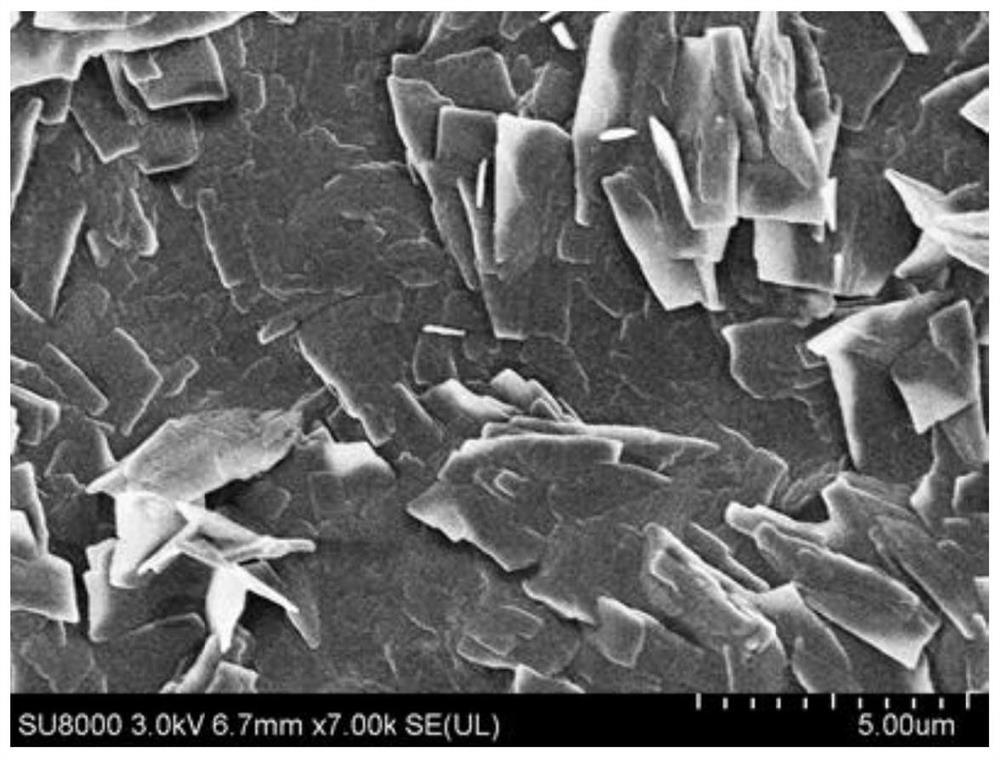

[0055] Step 3: Prepare a waterproof and breathable layer of ADK micro-nano composite structure on the cellulose-anthocyanin porous film obtained in step 2 by embossing process, as follows:

[0056] Embossing scheme

[0057] Grind the block of alkyl ketene dimer (AKD) into powder; place the ground AKD powder on the P...

Embodiment 2

[0060] Step 1: Put 0.7g of anthocyanin powder into a beaker, add 10ml of deionized water, and stir with a magnetic stirrer for 45 minutes at room temperature, so that the anthocyanin powder is fully mixed in deionized water to obtain an anthocyanin solution; 0.8 g of glycerin was added dropwise to 5 g of CNFs suspension, and then stirred at room temperature for 30 minutes to obtain a film-forming base solution; 1.0 ml of anthocyanin solution and 4 ml of film-forming base solution were mixed to obtain a mixed solution.

[0061] Step 2: Pour the mixed solution into a polytetrafluoroethylene mold to obtain a cellulose-anthocyanin porous film, such as image 3 shown.

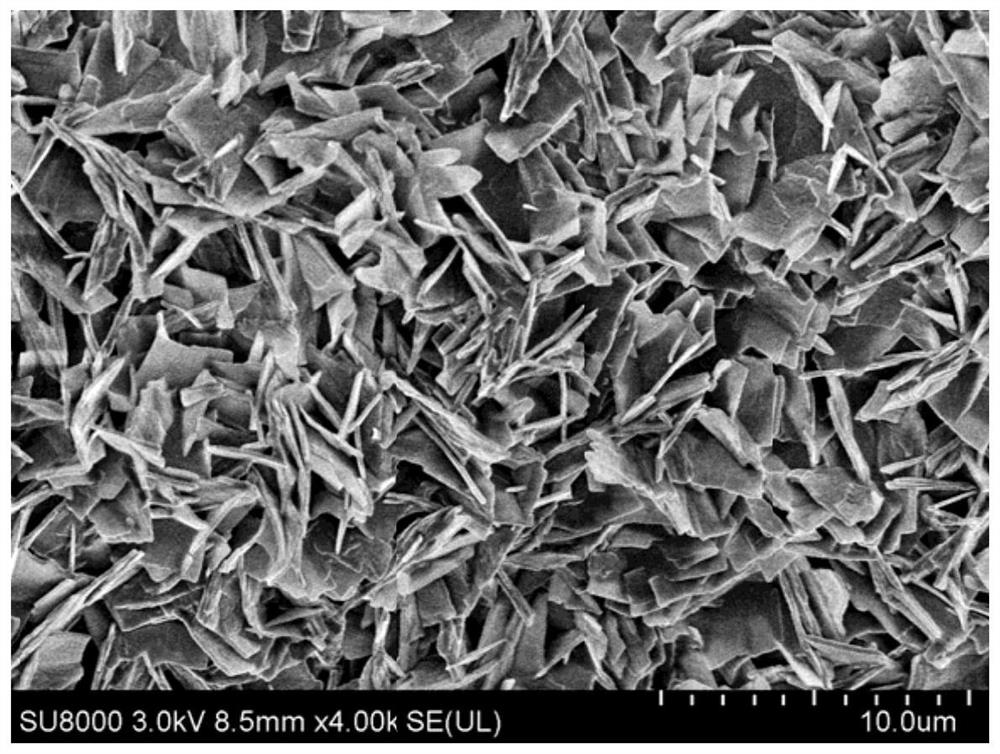

[0062] Step 3: Prepare a waterproof and breathable layer of ADK micro-nano composite structure on the cellulose-anthocyanin porous film obtained in step 2 by using 3D printing technology.

[0063] 3D printing solution

[0064] Take by weighing 10g alkyl ketene dimer (AKD) bulk body, put it into the agate mortar an...

Embodiment 3

[0066] Step 1: Put 1.5g of anthocyanin powder into a beaker, add 10ml of deionized water, and stir with a magnetic stirrer for 30 minutes at room temperature, so that the anthocyanin powder is fully mixed in deionized water to obtain an anthocyanin solution; 1.5 g of glycerin was added dropwise to 5 g of CNFs suspension, and then stirred at room temperature for 30 minutes to obtain a film-forming base solution; 1.2 ml of anthocyanin solution and 4 ml of film-forming base solution were mixed to obtain a mixed solution.

[0067] Step 2: Pour the mixed solution into a polytetrafluoroethylene mold to obtain a cellulose-anthocyanin porous film, such as image 3 shown.

[0068] Step 3: Prepare a waterproof and breathable layer of ADK micro-nano composite structure on the cellulose-anthocyanin porous film obtained in step 2 by embossing process, as follows:

[0069] Embossing scheme

[0070] Grind the block of alkyl ketene dimer (AKD) into powder; place the ground AKD powder on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com