Ploughing layer soil stripping device and stripping method thereof

A stripping device and ploughing layer technology, applied in the fields of ploughing equipment, dry gas arrangement, agricultural machinery and implements, etc., can solve the problems of reduced topsoil stripping rate, affecting topsoil stripping benefits, and inability to soil stripping, etc., to ensure the stripping rate, improve the Benefit, prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

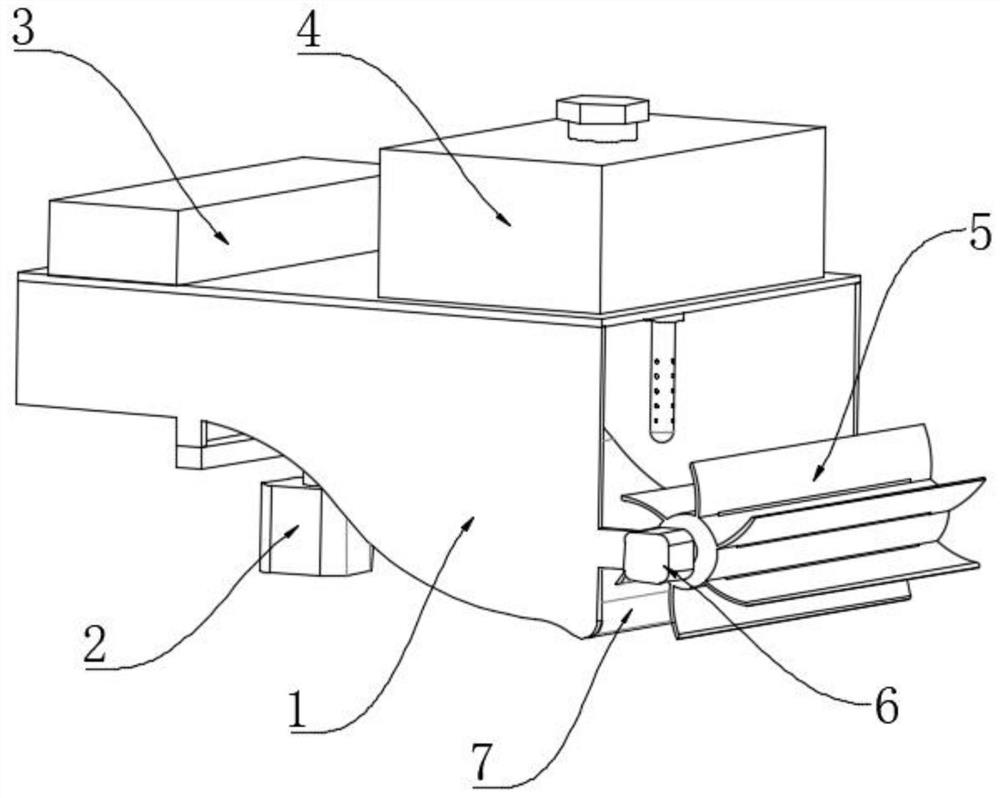

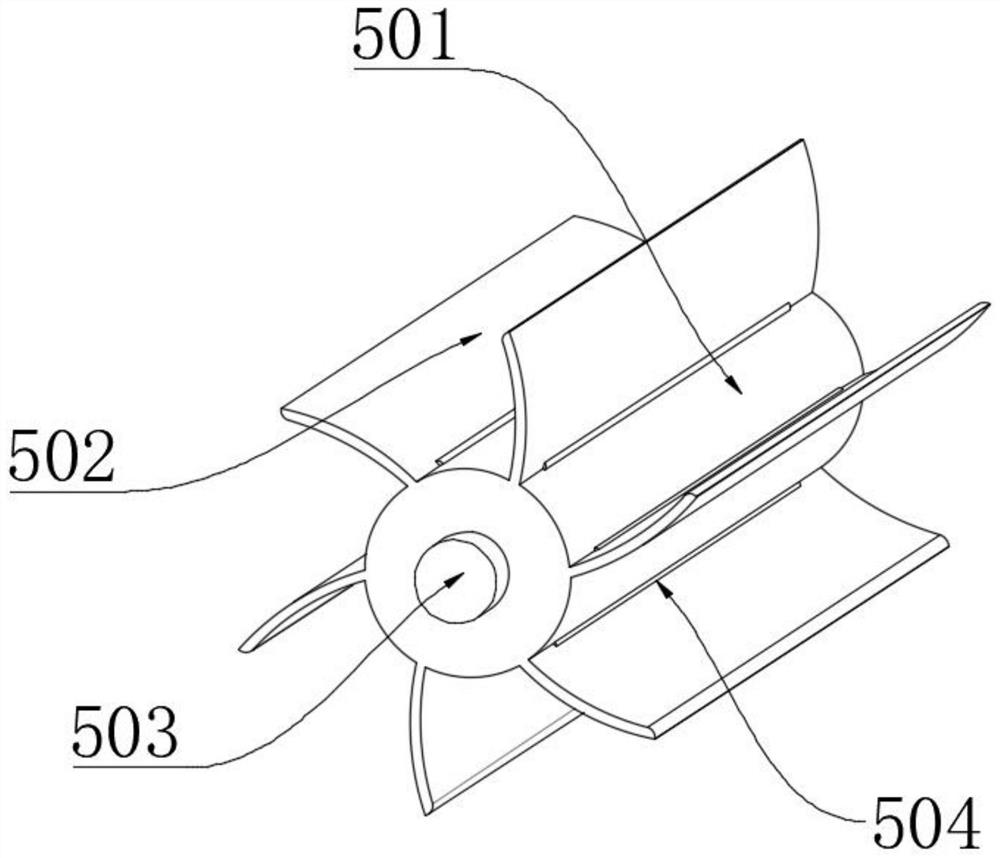

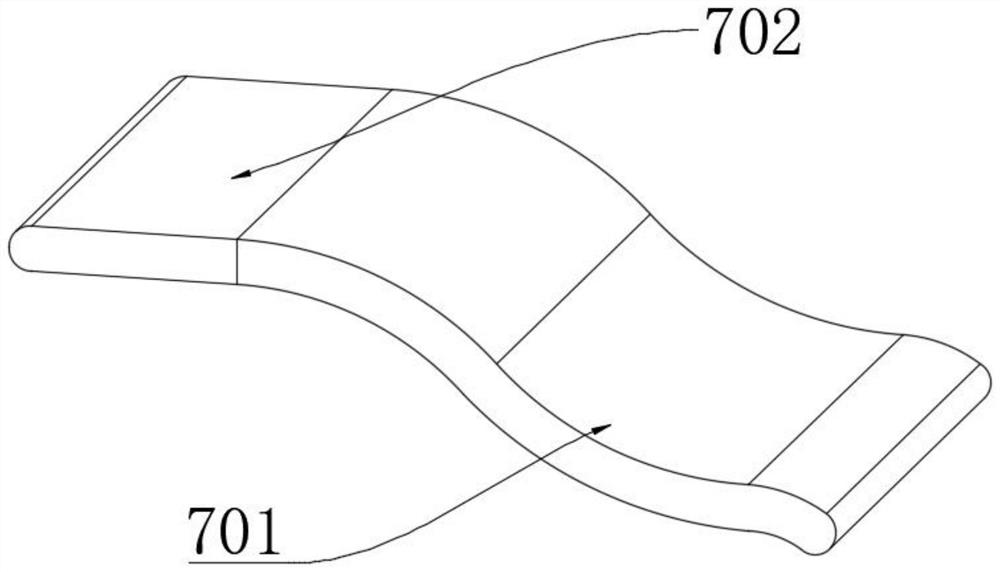

[0045] A stripping device for plow layer soil, such as figure 1 As shown, it includes a peeling shell 1, a hydraulic telescopic machine 2, a peeling mechanism 5, and a transmission mechanism 7; the outer wall of one side of the peeling shell 1 is fixedly connected with a drive motor 6; the outer wall of one side of the output shaft of the drive motor 6 is connected by a coupling On the outer wall of one side of the peeling mechanism 5; the outer wall of the top end of the output shaft of the hydraulic telescopic machine 2 is fixedly connected to the outer wall of the bottom end of the peeling shell 1; Water tank 4; the outer walls on both sides of the transmission mechanism 7 are fixedly connected to the inner wall on one side of the peeling shell 1; the operating hydraulic telescopic machine 2 moves the device up and down to ensure that the soil at the bottom will not be damaged when the soil is peeled off. The surface soil is stripped, and the stripped soil is sent to the tran...

Embodiment 2

[0051] A stripping method of a stripping device for cultivated layer soil, comprising the following steps:

[0052] S1: Survey the soil conditions in the designated project area;

[0053] S2: Evaluate the soil according to the investigation report of the soil condition;

[0054] S3: Formulate a soil stripping utilization plan and estimate the amount of stripped earthwork;

[0055] S4: Install the soil stripping device on the transport vehicle and strip the soil in the area;

[0056] S5: Collect, store and transport the stripped soil to a designated location;

[0057] S6: Return the stripped soil to the designated location, and calculate the amount of soil stripped from the topsoil.

[0058] The formula for calculating the amount of stripped soil from the topsoil is:

[0059]

[0060] Q-soil stripping amount in the stripping area, m 3 ;

[0061] h i -The stripping thickness of the i-th topsoil stripping unit, m;

[0062] S i -The stripping area of the i-th topsoil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com