A kind of preparation method of biofilm for sewage treatment

A sewage treatment and biofilm technology, applied in the adjustment method of biological treatment, water treatment parameter control, biological water/sewage treatment and other directions, can solve the problems of affecting sewage treatment efficiency, biofilm aging and demoulding, low film hanging rate, etc. , to achieve the effect of improving sewage treatment capacity, good sewage purification, and improving growth and reproduction ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

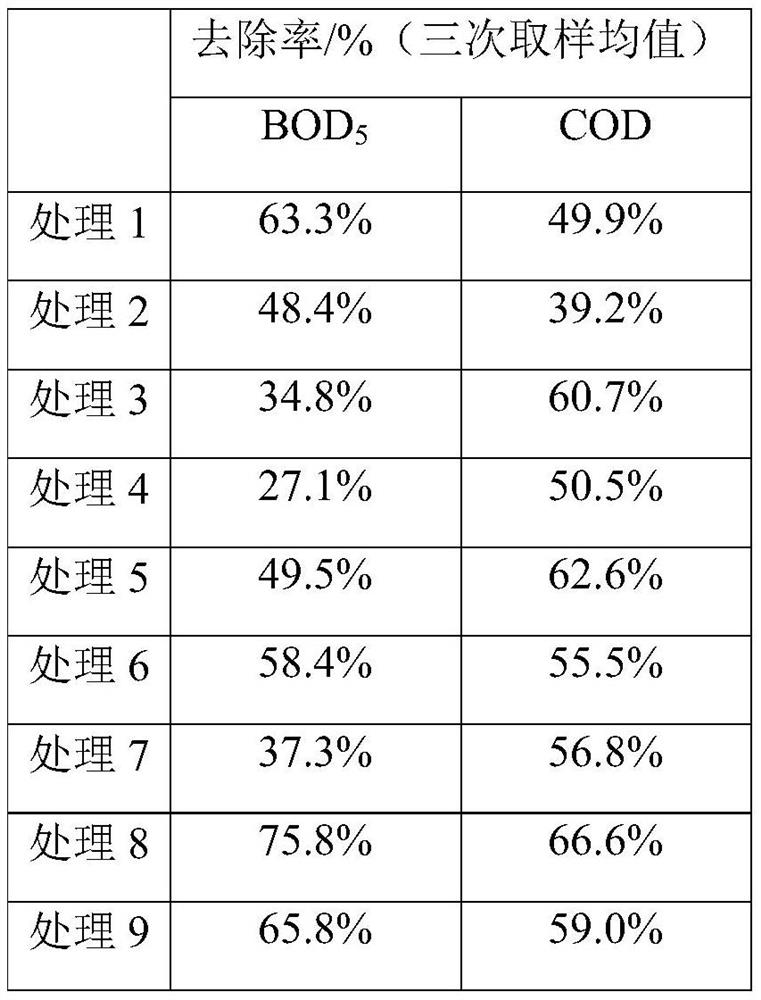

[0031] Example 1-Selection of bacteria and algae liquid

[0032] This example provides the sewage purification effect of several groups of bacteria and algae liquids.

[0033] Treatment 1: Roseobacter bacterial solution

[0034] Treatment 2: Bacillus licheniformis (Baclicus lincheniformis) bacterial solution

[0035] Treatment 3: Bacillus cereus bacterial solution

[0036] Treatment 4: Microcystis aeruginosa algal liquid

[0037] Treatment 5: Scenedesmus carinatus algal fluid

[0038] Treatment 6: Roseobacter (Roseobacter) bacterial liquid + Bacillus licheniformis (Baclicus lincheniformis) bacterial liquid

[0039] Treatment 7: Bacillus cereus (Bacillus cereus) bacterial liquid + Bacillus licheniformis (Baclicus lincheniformis) bacterial liquid

[0040] Treatment 8: Roseobacter bacterial solution + Bacillus licheniformis bacterial solution + Scenedesmus carinatus algal solution

[0041] Treatment 9: Bacillus cereus (Bacillus cereus) bacterial liquid + Bacillus lichenifor...

Embodiment 2

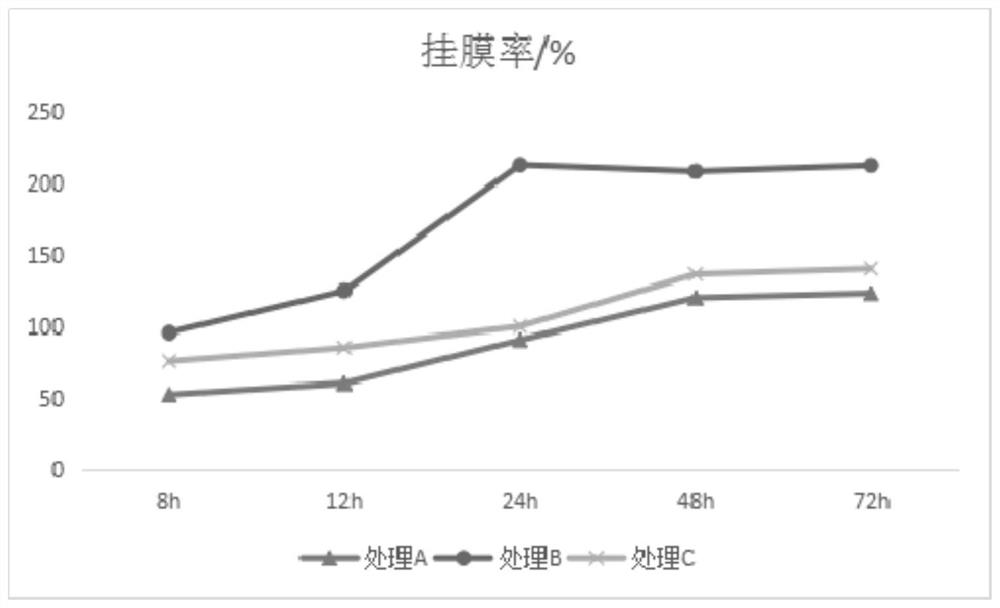

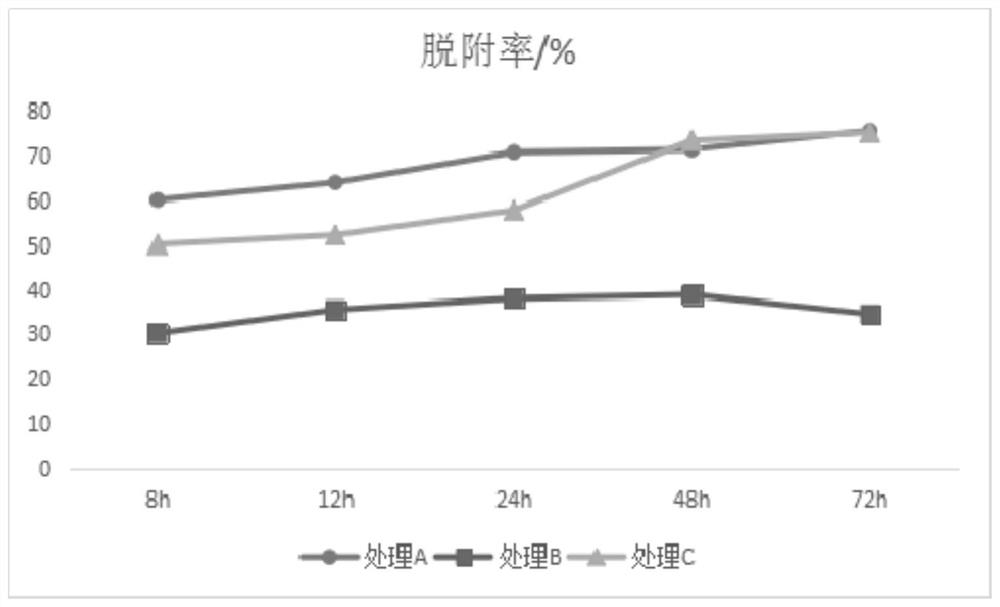

[0048] Embodiment 2-Investigation of film hanging rate and desorption rate

[0049] The film hanging rate and desorption rate of Treatment 8 in Example 1 were tested, and it was found that the effect of the film hanging rate and the desorption rate was not ideal. After continuous experiments, the optimal biofilm culture scheme was found. Part of the test process and results are as follows:

[0050] Determination method of film hanging rate:

[0051] Dry the carrier, weigh it, and record the original weight of the carrier; the carrier is treated with film for 8h, 12h, 24h, and 48h, respectively, and the carrier after filming is taken out, dried, weighed, and the sum of the mass of the carrier and the biofilm is recorded.

[0052] The film hanging rate = (the sum of the mass of the carrier and the biofilm after hanging the film - the original weight of the carrier) / the original weight of the carrier

[0053] Desorption rate determination method:

[0054] Take the carrier afte...

Embodiment 3

[0063] Example 3 - Optimization of Biofilm Carriers

[0064] Preliminary tests show that the fiber fabric woven with bamboo charcoal fiber and seaweed fiber has better film hanging rate, the most efficient film hanging efficiency and the lowest film release rate. However, where the film removal rate reaches more than 30%, it is still necessary to further reduce the desorption of the biofilm from the carrier and improve the binding ability between microorganisms and microorganisms, and between microorganisms and carriers. It was found by accident that the carrier can further reduce the desorption rate after being treated in the following ways, and the demoulding rate after 24h, 48h and 72h of film hanging culture is not higher than 10%.

[0065] Carrier handling method:

[0066] The carrier is: a fiber fabric made of bamboo charcoal fiber as the weft and seaweed fiber as the warp through an air-jet loom. The warp density is 34-50 pieces / hour, the weft density is 38-42 pieces / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com