Electronic atomized liquid with liquid leakage prevention function

An electronic atomization and anti-leakage technology, which is applied in the fields of tobacco, food science, and tobacco preparation, can solve the problems of fast aroma volatilization, easy liquid leakage, and inconvenient storage and transportation, so as to maintain the taste of smoking and reduce absorption obstruction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] An electronic atomization liquid with anti-leakage function, its raw material components are shown in Table 1, and its preparation method includes the following steps:

[0038] Step 1: Put the e-liquid base oil, vegetable oil, nicotine, and organic acid into the stirring tank according to the dosage in Table 1 and mix, heat to 45°C, stir at a speed of 100r / min for 15 minutes to disperse evenly, and obtain the basic e-liquid;

[0039] Step 2: According to the dosage in Table 1, put the food glue, phytosterol, and flavor into the stirring tank to mix with the basic e-liquid, raise the temperature to 75°C, stir at a speed of 60r / min for 30min to disperse evenly, discharge the material and place it in a In the refrigerator, let it stand and cool down to 20°C to obtain a gelled electronic atomization liquid.

Embodiment 2

[0041] An electronic atomization liquid with anti-leakage function, its raw material components are shown in Table 1, and its preparation method includes the following steps:

[0042] Step 1: Put the e-liquid base oil, vegetable oil, nicotine, and organic acid into the stirring tank according to the dosage in Table 1 and mix, heat to 55°C, stir at a speed of 100r / min for 15 minutes to disperse evenly, and obtain the basic e-liquid;

[0043] Step 2: According to the dosage in Table 1, put food glue, phytosterols, and flavors into the stirring tank and mix them with the basic e-liquid, heat up to 80°C, stir at a speed of 60r / min for 30min to disperse evenly, discharge and place in In a constant temperature room, let it stand and cool down to 25°C to obtain a gelled electronic atomization liquid.

Embodiment 3~8

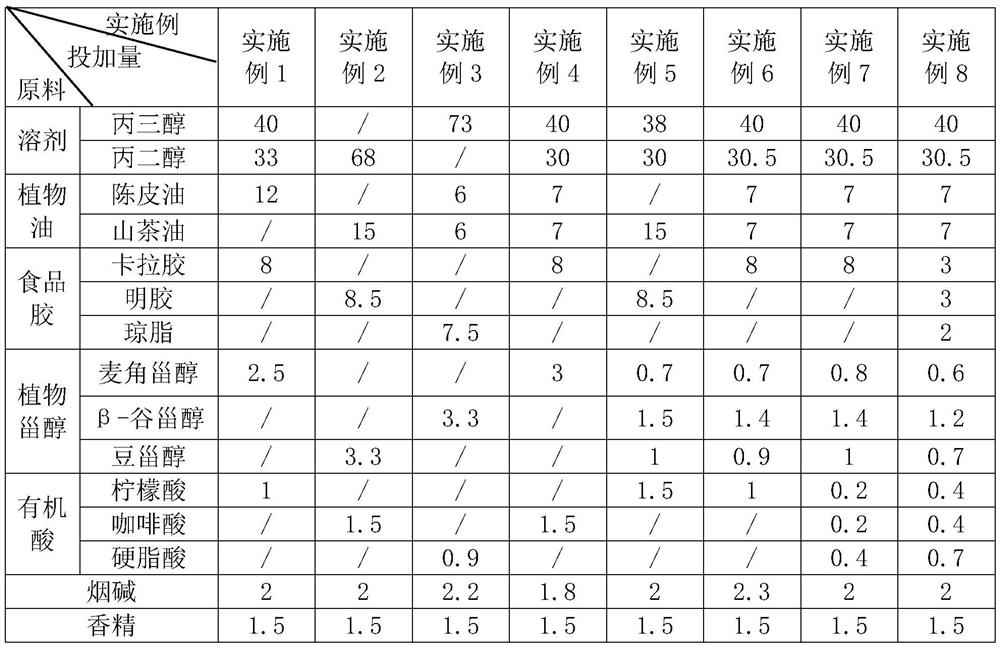

[0045] The difference from Example 1 is that the raw materials and dosage are different. The dosage of each raw material in Examples 3-8 is shown in Table 1 for details.

[0046] The dosage of each raw material of table 1. embodiment 1~8 (unit: 10 -2 kg)

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com