Anti-crystallization water seal device applied to ammonia-containing medium storage barrel and medium recovery method

A water-sealing device and anti-crystallization technology, applied in packaging, transportation and packaging, containers, etc., can solve the problems of poor liquid fluidity, insignificant melting effect, and regular dismantling and cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

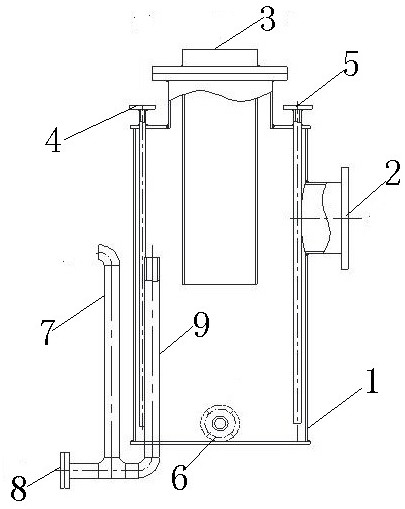

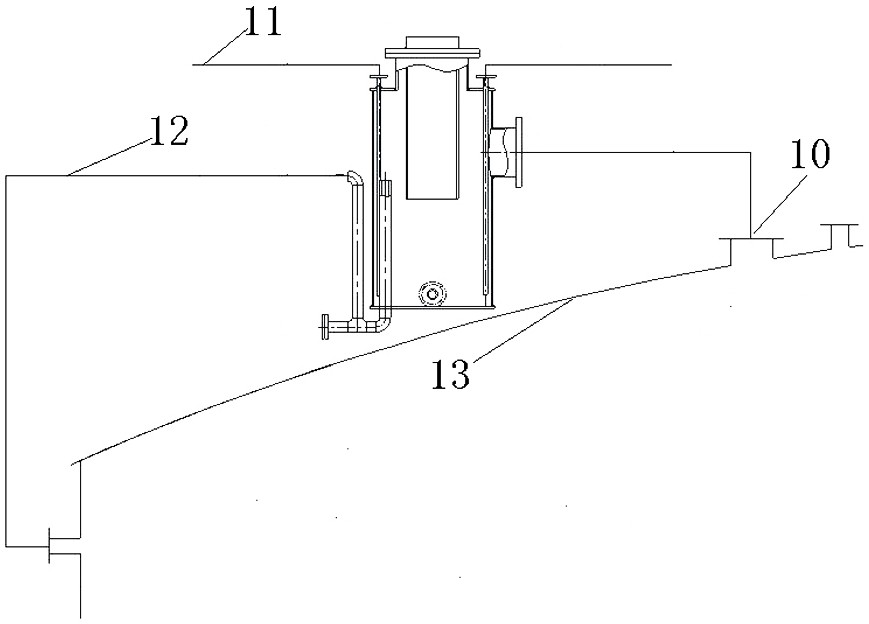

[0023] figure 1 It is a structural schematic diagram of the anti-crystallization water sealing device applied to the ammonia-containing medium storage tank of the present invention.

[0024] An anti-crystallization water seal device applied to ammonia-containing medium storage tanks such as figure 1 As shown, it includes the water-sealed bucket body 1, which is fixedly installed on the air inlet 2 on the side wall of the water-sealed bucket body 1, which is fixedly installed on the top of the water-sealed bucket body 1 and uses steel pipes to go deep into the water-sealed bucket from the top of the water-sealed bucket The air outlet 3 below the inner liquid level is fixedly installed on the body of the water-seale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com