High-temperature granular urea rapid cooling process and urea particle cooling equipment

A kind of cooling equipment and granular technology, which is applied in the field of high-temperature granular urea rapid cooling process and urea particle cooling equipment, can solve the problems of low heat dissipation efficiency of urea particle size, affect the quality of urea particles, and unfavorable environmental protection, etc., to reduce the temperature , Improve the cooling efficiency, the effect of uniform contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

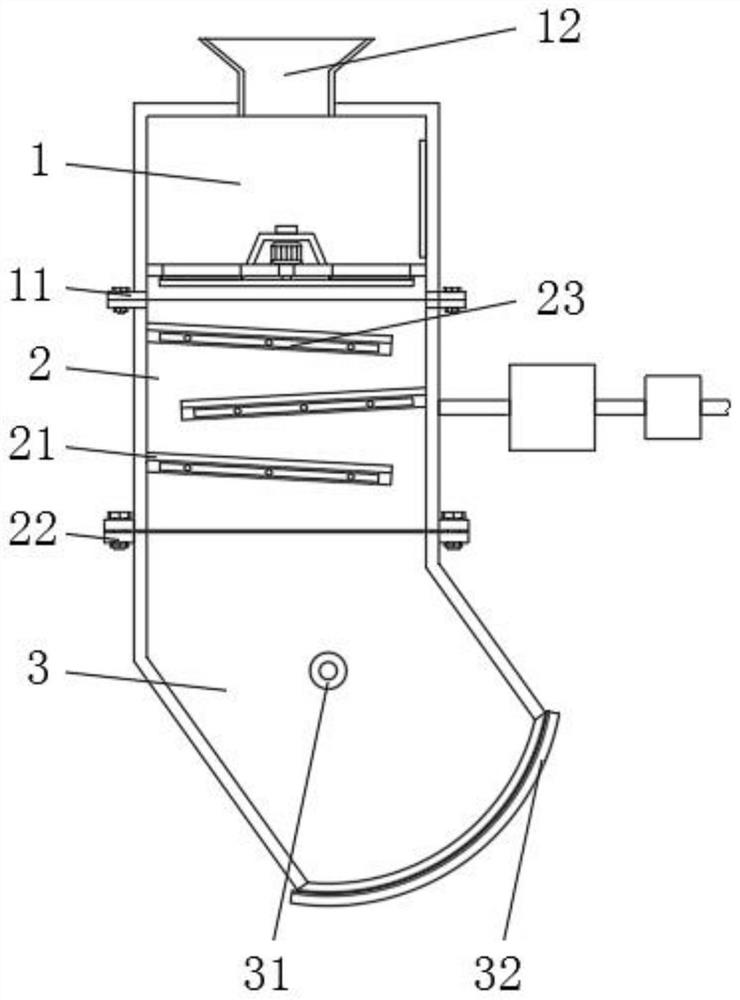

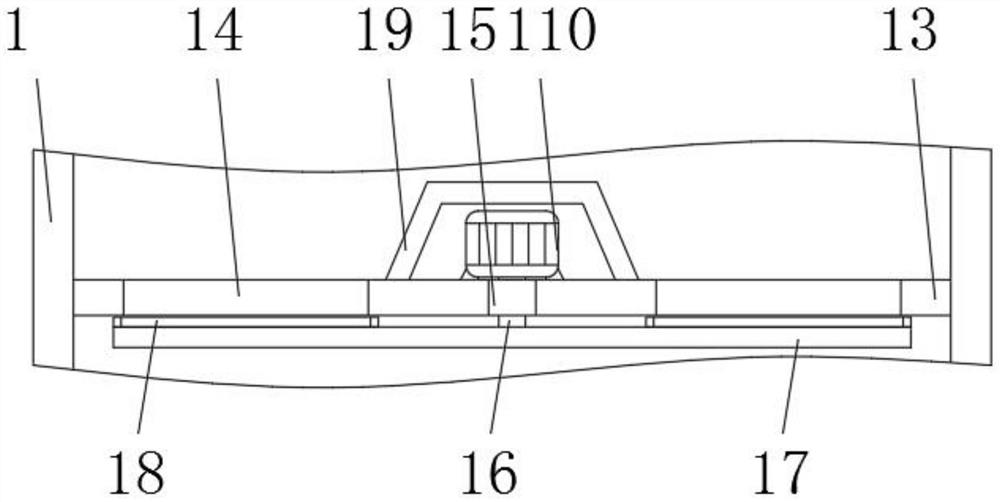

[0031] Embodiment 1: A high-temperature granular urea rapid cooling process and its urea particle cooling equipment, including a feed bin 1, a cooling cover 2, a discharge bin 3, a bearing plate 13, a shielding plate 17, a heat exchange plate 21 and a connecting pipe 26. The first flange 11 is installed on the outer wall side of the lower end of the feed bin 1, and the cooling cover 2 is connected to the feeding bin 1 through the first flange 11, and the second flange 22 is installed on the outer wall side of the lower end of the cooling cover 2, cooling The cover 2 is connected with the discharge bin 3 through the second flange 22, and the feeding cover 12 is installed on one side of the outer wall of the upper end of the feeding bin 1. The upper end of the inner wall of the feeding cover 12 adopts an open design, and the inner wall of the feeding bin 1 is A material level gauge is installed on the side, and the material level gauge can detect the amount of material on the upp...

Embodiment 2

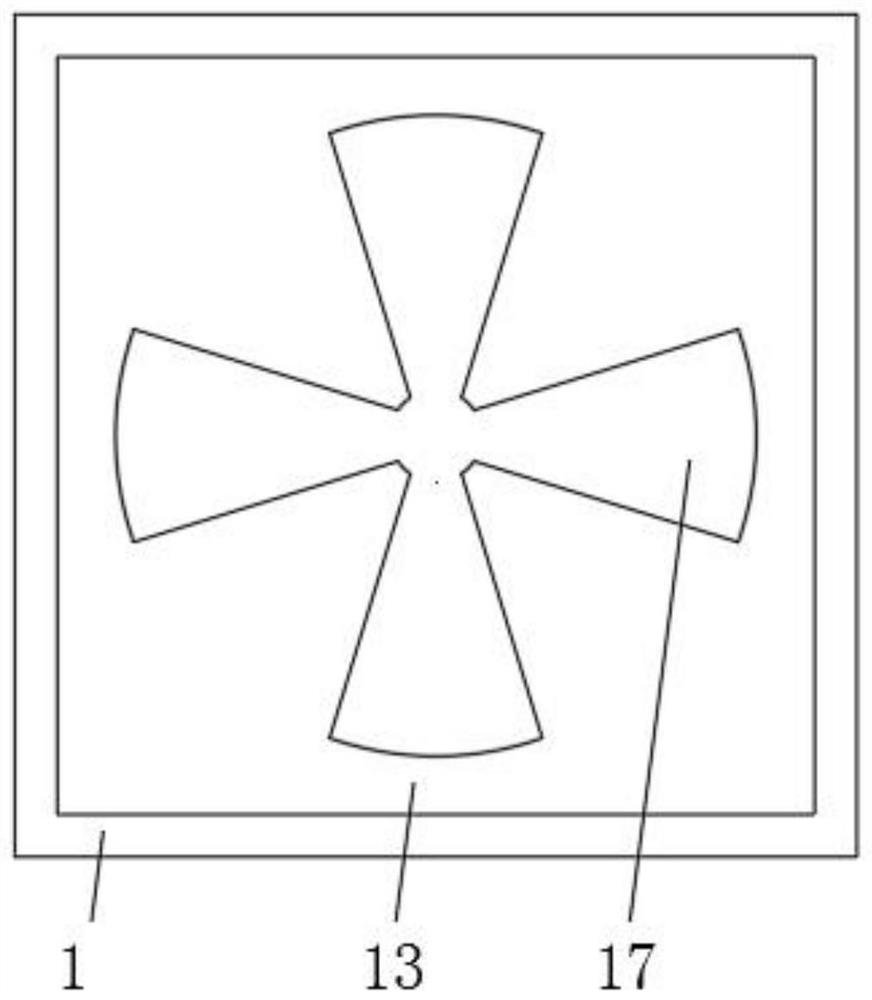

[0037] Embodiment 2: A high-temperature granular urea rapid cooling process and its urea particle cooling equipment, including a feed bin 1, a cooling cover 2, a discharge bin 3, a bearing plate 13, a shielding plate 17, a heat exchange plate 21 and a connecting pipe 26. The first flange 11 is installed on the outer wall side of the lower end of the feed bin 1, and the cooling cover 2 is connected to the feeding bin 1 through the first flange 11, and the second flange 22 is installed on the outer wall side of the lower end of the cooling cover 2, cooling The cover 2 is connected to the discharge bin 3 through the second flange 22. The inner wall of the cooling cover 2 is equipped with equidistant parallel heat exchange plates 21. The heat exchange plates 21 adopt a cross-shaped design, and there are heat exchange tanks inside the heat exchange plates 21. 23. The outer wall of the upper end of the heat exchange plate 21 adopts a corrugated design. The cooling water flowing throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com