Sintering positioning jig for SMD (Surface Mount Device) diode frame

A technology for positioning fixtures and diodes, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems that affect the pass rate of SMD diodes, and achieve the effect of ensuring stability and good functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

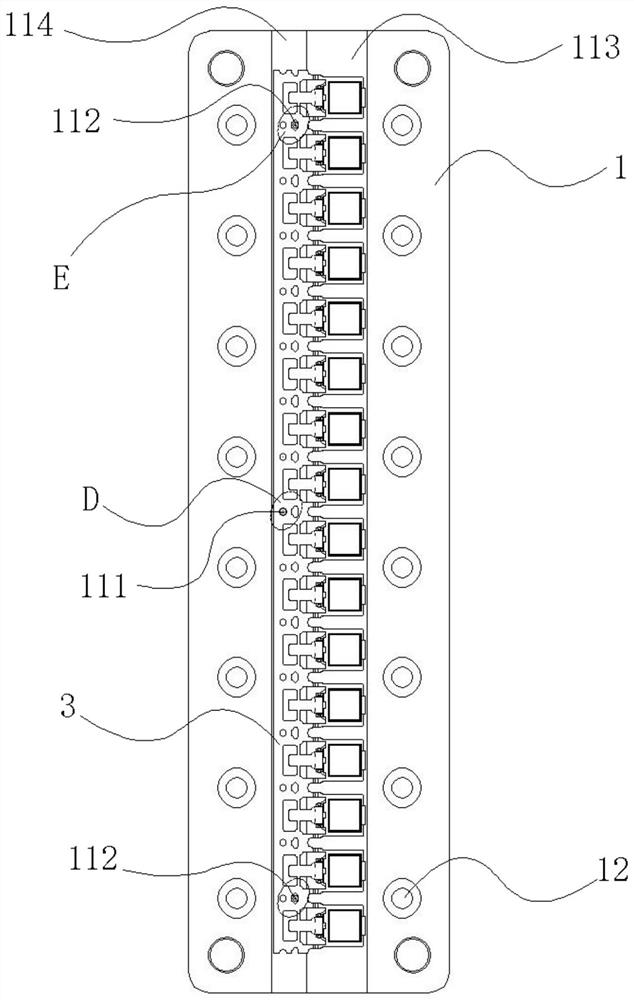

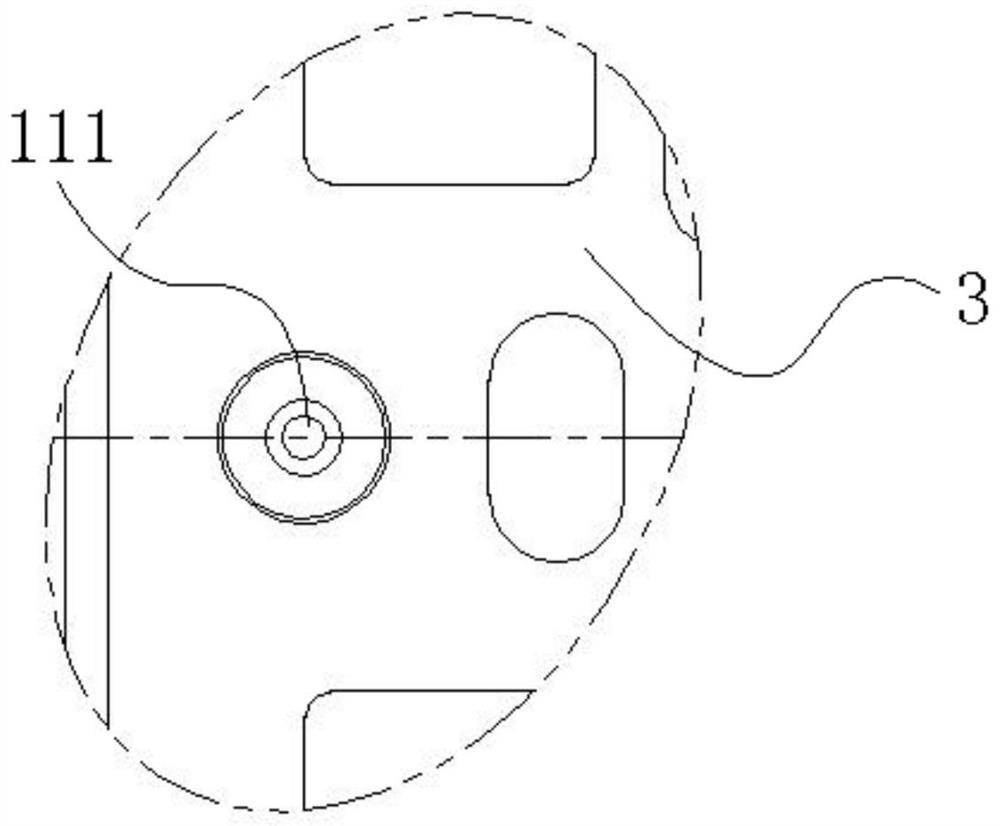

[0040]This embodiment provides a sintering positioning fixture for a chip diode frame, which includes a carrier plate 1, the carrier plate 1 is rectangular, and the upper end surface of the carrier plate 1 is provided with a storage slot 11, and the storage slot 11 is connected with the chip diode frame. 3 Adaptation, the bottom of the storage channel 11 is vertically provided with a positioning pin 111 and a guide pin 112. The storage channel 11 is composed of a placement slot 113 and a positioning slot 114 that are placed side by side, and the depth of the placement slot 113 is greater than that of the positioning slot. 114 depth, the SMD diode frame 3 can be placed stably after being bent and formed; the positioning groove 114 is provided with a relief hole 1141 matched with the cover plate positioning pin 21, and the diameter of the relief hole 1141 is not smaller than the cover plate positioning Twice the diameter of the pin 21, it can position the jig and the SMD diode fr...

Embodiment 2

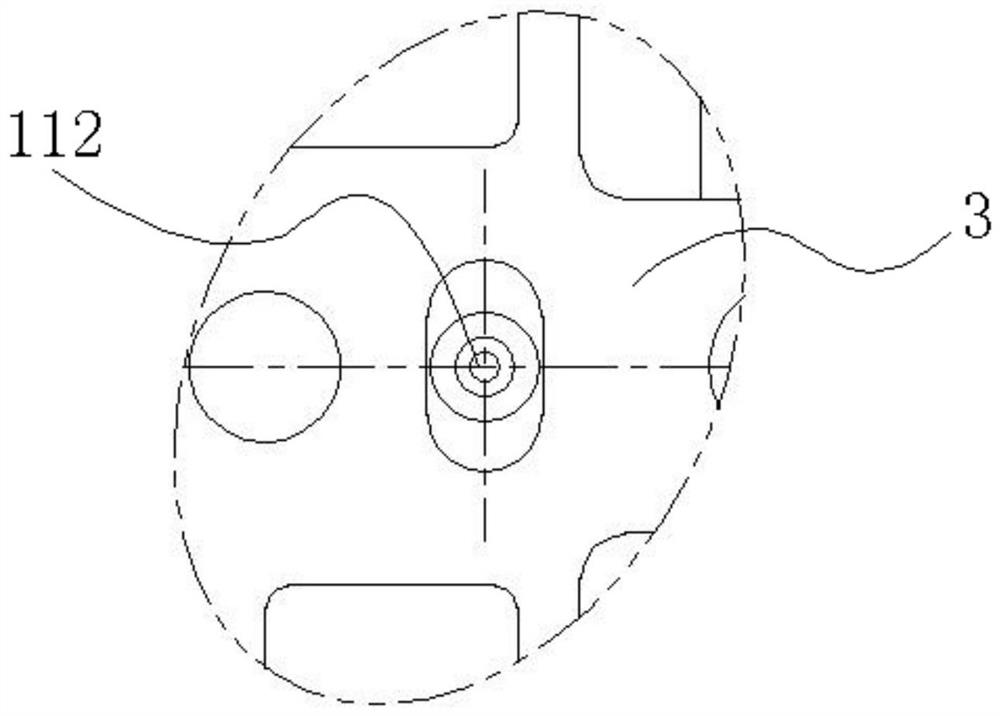

[0042] This embodiment provides a sintering and positioning fixture for a chip diode frame, which includes a carrier plate 1, the carrier plate 1 is rectangular, and the upper end surface of the carrier plate 1 is provided with a storage slot 11, and the storage slot 11 is made of parallel stickers. The tight placement groove 113 and the positioning groove 114 are formed. The depth of the placement groove 113 is greater than the depth of the positioning groove 114, so that the SMD diode frame 3 can be placed stably after being bent and formed. The bottom of the storage slot 11 is vertically provided with a positioning pin 111 And the guide pin 112, the positioning pin 111 is arranged in the positioning groove 114, which is convenient to adapt to the position of the circular positioning hole on the SMD diode frame, the described guiding pin 112 is arranged in the positioning groove 114, and the guiding pin 112 There are two, which are respectively matched with the oval guide hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com