Control unit, drive train, method for operating drive train and motor vehicle

A technology of control unit and drive system, which is applied in the direction of control drive, control system, electric vehicle, etc., and can solve problems such as noise reduction deterioration and noise increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

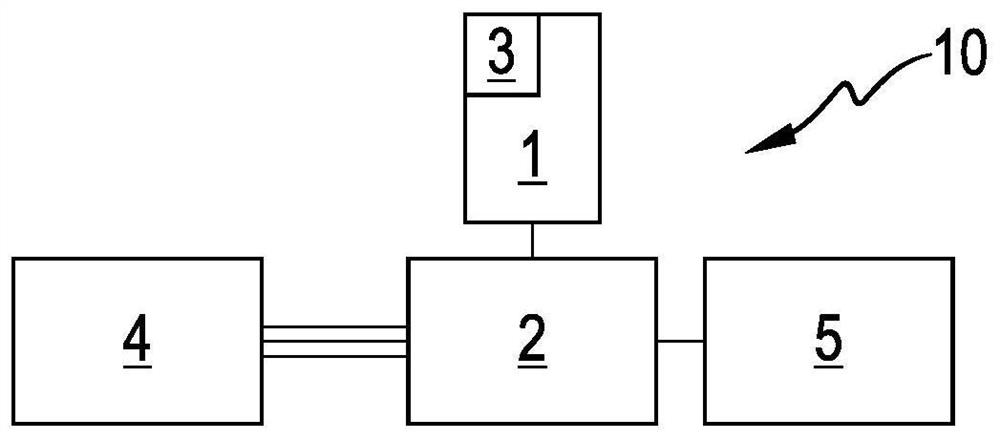

[0032] figure 1 A drive train 10 according to an exemplary embodiment of the invention is shown schematically with a control unit 1 according to an exemplary embodiment of the invention. Drive train 10 has, for example, a three-phase electric machine 4 , which is fed with phase currents from inverter 2 . For this purpose, the inverter 2 converts the DC voltage provided by the energy store 5 into AC voltages which, when connected to the terminals of the electric machine 4 , generate phase currents.

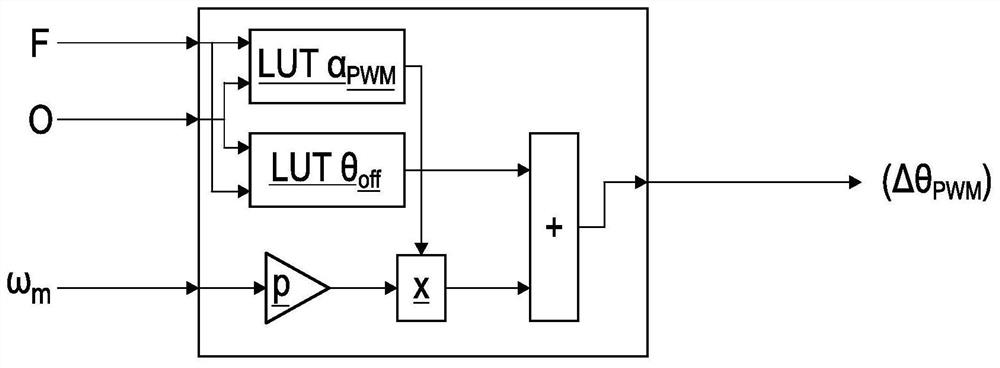

[0033] For this purpose, the inverter 2 has a plurality of semiconductor switches, preferably SiC semiconductor switches and / or GaN semiconductor switches. The semiconductor switches are controlled by the control unit 1 by means of pulse width modulation (PWM). When the electric machine 4 is in operation, unpleasant background noise is typically generated. In order to reduce these background noises, the control unit 1 has a noise reduction device 3 . The noise reduction device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com